API 5CT P110 Casing and Tubing Pipe

• Standards: API SPEC 5CT

• Grades: P110, J55/K55, N80, L80, L80, L80 13Cr, T95, Q125

• Stock Available: Yes

• Manufacturing process: Seamless, ERW

• Casing pipe dimension: 4-1/2” to 20”

• Tubing dimension: 1.050” to 4-1/2”

• Coupling thread: BTC, LTC, STC, premium connections threads, HYD, and equivalent.

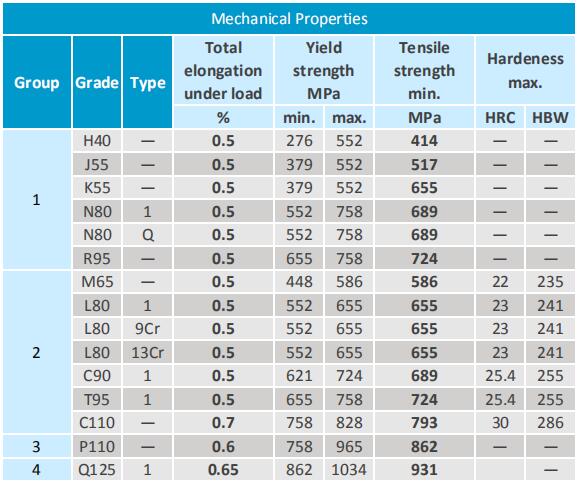

• Length: R1, R2, R3

API 5CT P110 casing and tubing pipe represents one of the highest grades of API 5CT steel pipes, specifically engineered for the demanding requirements of deep oil and gas wells. Compared with J55, K55, N80, L80, and T95 grades, P110 provides significantly greater mechanical strength and enhanced resistance to downhole stresses. It is defined by a minimum tensile strength of 862 MPa and a yield strength range of 758–965 MPa, placing it among the most robust tubular products in the oilfield industry, it is widely used for oil drilling and producing in a particular surroudings especially for a deep oil well.

In accordance with API 5CT specifications, P110 casing is identified with a white band at the pipe ends, signifying its superior strength classification. This grade is particularly suited for high-pressure, high-temperature (HPHT) drilling operations, sour service conditions, and wells with complex geological formations. By offering a reliable balance of toughness, resistance to collapse, and structural integrity, API 5CT P110 ensures safe and efficient production performance even in the harshest downhole environments.

API 5CT P110 Casing and Tubing stock

API 5CT P110 manufacturing types

P110 casing and tubing could be made by welded ERW or seamless and in most cases seamless type is adopted.

Heat treatment types for P110 pipes

P110 pipes shall be heat treated with full-body, full-length, as per API 5CT 10th edition quenched and tempered (simplified with Q) shall be adopted to the products. Normalized (N) or normalized and tempered (N&T) is not applicable for P110 casing and tubing.

Special chemical requirements for ERW P110 pipe are specified in Table E.4 in API 5CT, and other requirements specified in A.6 SR11.

Heat treatment is required for P110 grade

Because P110 is a high-strength grade, the heat treatment condition is not only a manufacturing requirement but also a critical acceptance checkpoint that supports predictable performance under downhole loading. When the purchase order references API 5CT Casing and Tubing Specification, the heat treatment condition (Q) should be verified alongside mechanical property compliance, hardness limits when specified, and the NDE scope required by the selected PSL level. This alignment helps reduce uncertainty in high-stress strings where performance margin is sensitive to both metallurgy and verification coverage.

Reference Inspection for P110 Casing and Tubing

• Visual inspection for pipe surface

• Dimension check

• NDT test including Magnetic particle, Ultrasonic Test, Hydrostatic Test

• Drift test

• Chemical analysis

• Mechanical test on tensile strength, yield strength and elongation

• Charpy impact test

• Flattening tests

• Hardness test

• Thread ends check with thread gauge and coupling check

In P110 procurement, inspection items become actionable only when they are delivered as a traceable documentation package that matches the purchase order. Typical deliverables include an MTC referencing heat number traceability, mechanical test results (yield/tensile/elongation), impact results where required, NDE reports for the specified methods and acceptance criteria, dimensional reports, and thread gauging records when threads and couplings are included. For standard definitions of PSL scope and how acceptance requirements are organized for casing and tubing products, reference API 5CT Casing and Tubing Specification.

API 5CT P110 Casing:

P110 Casing is installed downhole to provide structural integrity to the wellbore and must withstand external-collapse pressure from rock formations and internal-yield pressure from fluid and gas. It needs to bear its own weight and withstand the torque and transaxial pressure placed on it while running downhole. Casing is considered as a pipe pile that will stabilize the oil well.

API 5CT P110 Tubing:

P110 Tubing is installed inside the casing. It is used to transport (pump) crude oil or natural gas from the source rock to the ground wellhead. Inside tubing is sucker rods, where used for pumping oil and gas.

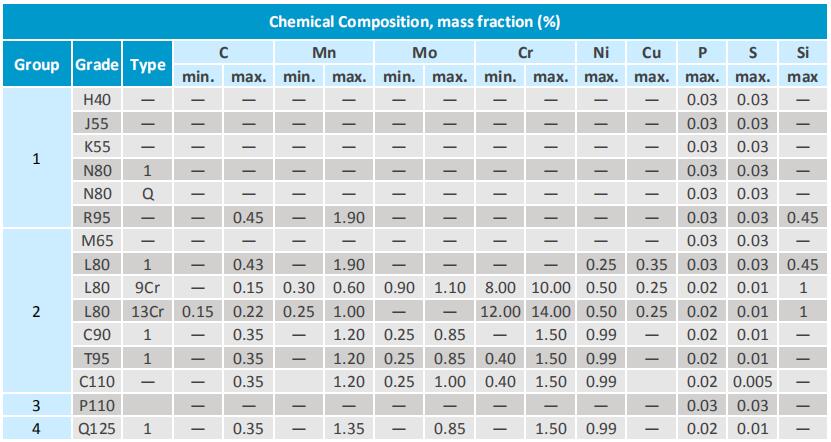

Chemical Composition

For seamless P110 pipe, only limits phosphorus and sulfer content 0.03%, and in case welded type, maximum P 0.02% and S 0.01%. Other chemical composition like C, Si, Mn, Mo, Cr no limits.

Mechanical Properties

Connection type, ends and Couplings

Casing and tubing ends type are different where for casing usually BTC and tubing with EUE or NU.

P110 casing pipe connection types

Common use connection BTC, buttress thread marked with BC

LC: Long round thread

SC: Short round thread

Premium connections like HYD, and other gas tight thread

Customized connection threads as per client requirement

P110 tubing connections with regulare and special clearance

EUE: External upset, tubing ends have an exeternal upset with a larger diameter and thickness than tubing body

NU: Non upset, tubing ends same diameter and thickness with tubing body

In high-strength programs, connection selection impacts sealing reliability under casing and tubing pressure changes. Standard API designations such as BTC for casing and EUE/NU for tubing define the baseline geometry, while premium threads may be specified for gas-tight performance and higher torque capacity.

Dimension and tolerances

Length Range:

R1: 4.88 to 7.62 meters, permissible variation max 1.83 meters, and permissible length min 5.49 meters.

R2: 7.62 to 10.36 meters.

R3: 10.36 to 14.63 meters.

Outer diameter tolerance:

For pipes below 4-1/2 inch, tolerances +/- 0.79mm or 0.031 inch

For pipes equal and above 4-1/2 inch, tolerances +1% and -0.5% of pipe diameter

Wall thickness tolerance – 12.5%.

Imperfections:

Maximum permissible depth of linear imperfections, external and internal imperfections 12.5 of wall thickness. In case required 5% also could be adopted for P110 grade.

Dimension and tolerance requirements are frequently used as field acceptance checkpoints for running and make-up readiness, especially when multiple strings must interface smoothly during completion. When verifying sizes for matched strings, the API tubing and casing chart can be used as a quick cross-check reference for common OD ranges and typical connection families, while detailed casing selection by size and grade can be reviewed on Steel Casing Pipe API 5CT.

Octal supply range for P110 casing and tubing

• Standards: API SPEC 5CT P110 Casing and Tubing

• Grades: P110

• Stock Available: Yes

• Manufacturing process: Seamless, ERW

• P110 Casing and Tubing Outer Diameter: 2-3/8”, 2-7/8”, 3-1/2”, 4-1/2”, 5-1/2”, 6-5/8”, 7”, 7-5/8”, 7-3/4”, 8-5/8”, 9-5/8”, 10-3/4”, 11-3/4”, 13-3/8”, 16”, 18-5/8”, 20”

• Thickness: 4 LB/FT to 106.59 LB/FT, 0.244” to 0.875”

• Coupling thread: BTC, Buttress (Regular, Special bevel or special clearance), LTC, STC, premium connections threads.

• Length: R1, R2, R3, customized

In Summary

In modern oilfield operations, the choice of casing and tubing directly influences well integrity, production efficiency, and long-term economic returns. With its superior tensile and yield properties, API 5CT P110 casing and tubing pipe stands out as the optimal solution for deep and challenging drilling projects. Its proven ability to withstand high stress, corrosive elements, and geological unpredictability makes it indispensable for safe hydrocarbon recovery.

As a trusted supplier, Octal Steel provides fully certified API 5CT P110 casing and tubing pipes, complete with inspection reports, mill test certificates (MTC), and full traceability. By adhering to international standards and implementing strict quality control, Octal Steel ensures that every pipe delivers both mechanical reliability and operational confidence. For oil and gas companies seeking dependable tubular solutions, Octal Steel’s P110 products offer not only material strength but also a foundation for long-term field success.

FAQ

Q1: What is API 5CT P110 casing and tubing used for?

A1: P110 is commonly used in deep or demanding wells where high mechanical strength and downhole integrity margin are required for casing strings and tubing strings.

Q2: Why is heat treatment emphasized for P110 grade?

A2: P110 is supplied in a quenched-and-tempered condition, and the heat treatment condition is a key acceptance checkpoint that supports predictable mechanical performance under high stresses.

Q3: Which connections are common for P110 casing and tubing?

A3: P110 casing commonly uses BTC and related casing thread families, while P110 tubing commonly uses EUE or NU; premium connections may be specified when gas-tight sealing or higher torque capacity is required.

Q4: Where can thread inspection and gauging practice be checked?

A4: Thread acceptance and gauging references can be cross-checked via API Coupling and Threads for Casing and Tubing.

Q5: Where can standard PSL scope and acceptance requirements be confirmed?

A5: PSL scope and acceptance requirements can be reviewed in API 5CT Casing and Tubing Specification, while product-level casing and tubing options can be cross-checked via Steel Casing Pipe API 5CT and OCTG Tubing, API 5CT Tubing.