ASTM A53 Grade A & B Steel Pipe

Supply Specifications:

ASTM A53 Grade A and B

Types: Seamless, Welded (ERW), Galvanized

Sizes: 1/2” to 20”

Thickness: Schedule 10, 40, STD, XS, to XXS

Ends: Plain, Beveled, Threaded

Length: 20 ft, 40 ft, customized

Coating: 3PE, FBE, Varnished, Black, Zinc Coated

As we know ASTM A53 Grade B pipe is always required with large quantities from different industries, so what is A53 pipe and how come it gets so popular?

Today we are going to introduce this kind of popular steel pipe.

First and also important to know, ASTM A53 Grade B pipe is the most common used grade in ASTM A53 standard. And it includes three types in pipeline systems:

a. Seamless type

b. Welded type (ERW, EFW, HFW, SAW)

c. Hot Dipped Galvanized type

Now we will try to explain the pipe specification from different sides:

Standard Specification of ASTM A53

Related test methods standard for making A53 pipe

Raw materials

A53 galvanized pipe specification

How many grades in ASTM A53

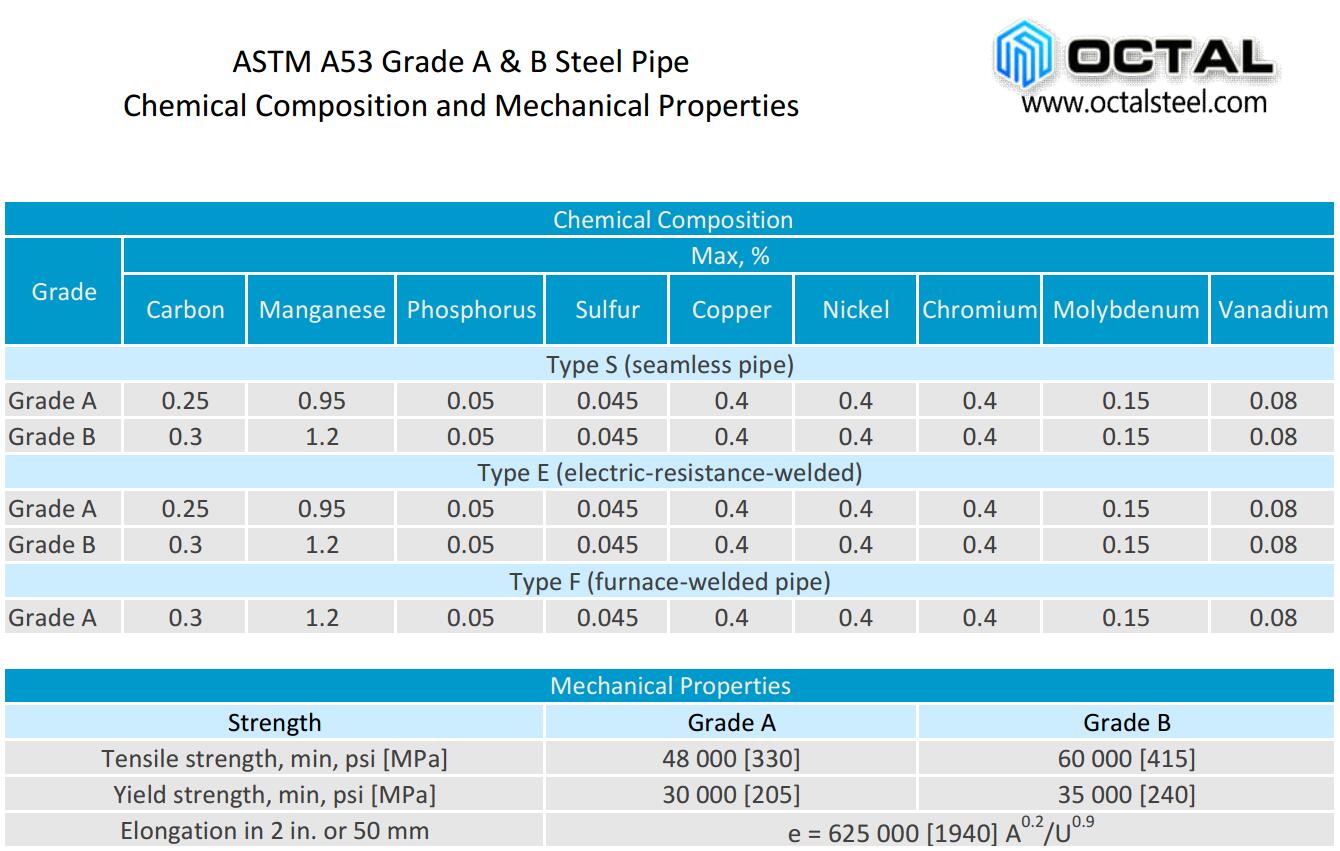

Chemical Composition

Yield Strength and Tensile Strength

How to make a right description for A53 pipe order

ASTM A53 standard specification

ASTM A53 is the standard specification for the carbon steel pipe in seamless, welded, and zinc-coated galvanized pipes. Covers the dimensions ranges from OD 10.3 mm (1/8 inch) to 660 mm (26 inch).

Applications

Transmission: Oil and gas pipeline systems, water treatment, mineral slurry

Construction and Structure: Buildings, underground water drilling, boiler water transmission

Machine Parts: Machining to spare parts

Power station: Wind Turbines, Anti-Static tube

Find here Differences between ASTM A53 and ASTM A106.

Related Standard for manufacturing ASTM A53 Grade B pipe

a. A90/ A90M The standard for the test plan of coating on the pipe or steel products, with Zinc or Zinc alloy coatings.

b. A370 The standard for the test plan and definitions for mechanical testing of steel products.

c. A 530/A 530M The standard for the common requirements for the carbon and alloy steel pipe.

d. A 700 The plan for packing, marking and loading of steel products for shipment.

e. A 751 The test plan for chemical analysis of pipes and steel plates, steel products.

f. A 865 The definitions for threaded coupling, carbon steel and hot galvanized zinc coated welded and seamless, for the joints of the steel pipe.

g. B 6 The standard specification of the zinc.

h. E 29 The plan for using significant digits in test data to value the conformance with the specification.

i. 213 The plan for the test of ultrasonic, for the steel pipe in welded and seamless.

j. 309 The plan for eddy current test and magnetic configuration

k. E 570 The plan for the flux leakage test of ferromagnetic steel pipe products

l. E 1806 The plan for steel sampling and chemical composition of iron for determination

Raw materials of ASTM A53 pipe

The steel for making ASTM A53 pipe (both for seamless and welded) shall be according following processes: open hearth electric furnace, or basic oxygen.

Raw steel material of different grades are independently strand cast identification of resultant transition material is needed. Manufacturer should remove transition material by any established procession that could clearly separate the grades.

The welding seam for ERW welding processes in ASTM A53 Grade B pipe should be done heat treatment after welding to a min of 540℃ 1000℉.

Consequently, there is no untempered martensite remains, or use the other ways of non untempered martensite remains.

In case the pipe is cold expanded, the expansion amount shall not exceed 1 1/2% of the pipe diameter.

How many grades in ASTM A53 standard

a. Seamless Type S, has grade A and B.

b. Welded Type E (ERW), Grade A and B.

c. Furnace Welded Type F, Grade A only.

Galvanized (Zinc Coated) Standard Requirements

ASTM A53 standard specification including hot dipped galvanized (zinc coated) requirements for ASTM A53 Grade B pipe.

Moreover, there are pipe internal and external galvanization. By the hot dip procedures, zinc thickness of any grade shall be complied to specification B 6.

Zinc coating weight should be not less than 1.8 oz/ft2, 0.55 kg/m2, and each sample weight shall not be not less than 1.6 oz/ft2 0.49 kg/m2, meanwhile sample outside surface and inside surface weight shall not be less than 1.3 oz/ft2 0.40 kg/m2.

Chemical composition and mechanical properties of A53

There are two methods to specify the elongation in ASTM A53 standard:

Methode A, By equation: e = 625 000 [1940] A^0.2/U^0.9

Explanations:

e = minimum elongation in 2 inch (50mm) in percent rounded to the nearest percent

A = specimen cross-sectional area, rounded to 0.01 in.^2 (1 mm^2), based on the specified outside diameter to the nominal specimen width and wall thickness. If the area calculated is equal or above than 0.75 in.^2 (500 mm^2), then the value 0.75 in.^2 (500 mm^2) shall be applied, and

U = specified tensile strength, psi (Mpa)

Methode B, See table X4.1 or Table X4.2 in ASTM A53 elongation specification. Where for specimen area 0.75 in.^2 and greater, Elongation in 2 in. and min % at 30% for A53 Grade B pipe. (Tensile strength 415 Mpa)

Our Supply Range for ASTM A53 pipe (Seamless and ERW available for stock)

Octal is capable of supply ASTM A53 pipes as below:

Standard and grades: ASTM A53 Grade A, B. Type E, F, S

Manufacturing types: Seamless, Welded (ERW), Hot-Dipped Galvanized

Pipe Dimensions Range: NPS 1/8” to 20”

Pipe Schedule Range: SCH 10 to SCH 160 and SCH XXS

Ends: Plain, Beveled, threaded. With couplings.

Length range: Fixed length 20 ft and 40 ft, single random length, double random length

Coating: Black paint, anti-rust oil, varnished, galvanized, zinc coating thickness weight is 550g/m2