ASTM A672 Grade B60, C65 Pipe Specification

ASTM A672 GRADE B60, C65, refers to ERW welded pipe used high-pressure services in moderate temperatures. Those pipes are fabricated from pressure vessel plates like ASTM A285, ASTM A515, ASTM A516, and ASTM A537.

ASTM A672 Standard Specification

The specification covers steel pipe manufactured in Electric-Fusion-Welded with filler metal added, fabricated from pressure-vessel quality steel plate of any of several analyses with different strength levels, suitable for high-pressure service at moderate temperatures. Heat treatment may or may not be required to attain the desired properties or to comply with applicable code requirements. Supplementary requirements are provided for use when additional testing or inspection is desired.

Dimension Range

ASTM A672 normally includes the pipe in and above 16inch 406mm diameter with all thicknesses up to 3inch 75mm. Pipes with other dimensions may be furnished provided it complies with all other requirements of this specification.

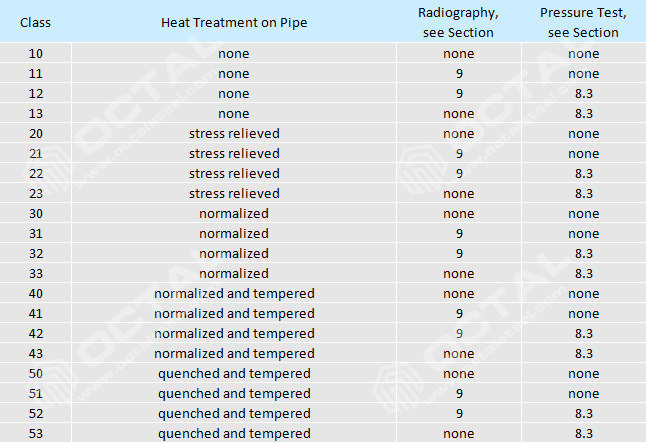

There are several classes in this specification from 10 to 53, common use classes 11, 12, 13, 20, 21, 22 and etc. Detailed class designation is as follows:

Referred documents standard:

ASTM A20 Specification for General Requirements for Steel Plates for Pressure Vessels.

ASTM A370 Test Methods and Definitions for Mechanical Testing of Steel Products

ASTM A435/A 435M Specification for Straight-Beam Ultrasonic Examination of Steel Plates

ASTM A530/A 530M Specification for General Requirement for Specialized Carbon and Alloy Steel Pipe

ASTM A578/A 578M Specification for Straight-Beam Ultrasonic Examination of Rolled Steel Plates for Special Applications

ASTM E 109 Method for Dry Powder Magnetic Particle Inspection

ASTM E 138 Method for Wet Magnetic Particle Inspection

ASTM E 165 Test Method for Liquid Penetrant Examination

ASTM E709 Guide for Magnetic Particle Testing

Plates standard

ASTM A202/A 202M Specification for Pressure Vessel Plates, Alloy Steel, Chromium-Manganese-Silicon

ASTM A204/A 204M Specification for Pressure-Vessel Plates, Alloy Steel, Molybdenum

ASTM A285/A 285M Specification for Pressure Vessel Plates, Carbon Steel, Low and Intermediate-Tensile Strength

ASTM A299/A 299M Specification for Pressure Vessel Plates, Carbon Steel, Manganese-Silicon

ASTM A302/A 302M Specification for Pressure Vessel Plates, Alloy Steel, Manganese-molybdenum and Manganese Molybdenum-Nickel

ASTM A515/A 515M Specification for Pressure Vessel Plates, Carbon Steel, for Intermediate- and Higher-Temperature Service

ASTM A516/A 516M Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service.

ASTM A533/A 533M Specification for Pressure Vessel Plates, Alloy Steel, Quenched and Tempered, Manganese-Molybdenum and Manganese-Molybdenum-Nickel

ASTM A537/A 537M Specification for Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel

Heat Treatment

All calsses other than 10, 11, 12 and 13 shall be heat treated in furnace controlled to +/-25℉ (14℃) and equipped with a recording pyrometer so that heating records are available. Heat treating after forming and welding shall be to one of following:

Classes 20, 21, 22, and 23 pipe shall be uniformly heated within the post-weld heat-treatment temperature range indicated in Table 2 for a minimum of 1 h/in. Of thickness or 1h, whichever is greater.

Classes 30, 31, 32, and 33 pipe shall be uniformly heated to a temperature in the austenitizing range and not exceeding the maximum normalizing temperature indicated in Table 2 and subsequently cooled in air at room temperature.

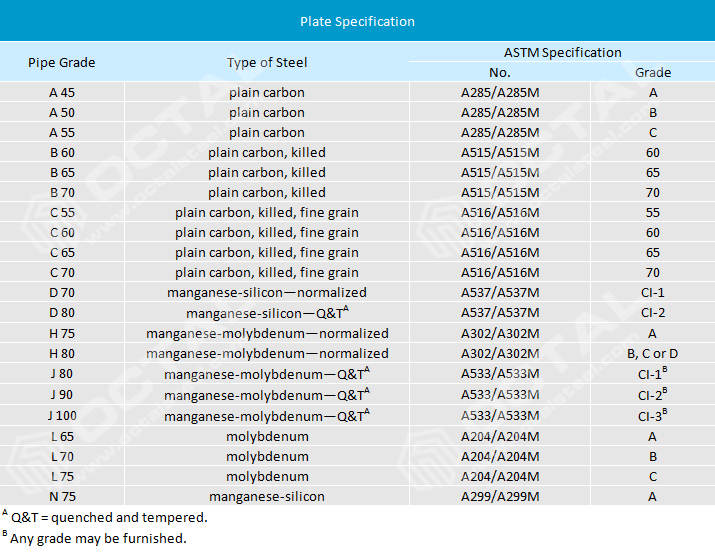

Grades included in ASTM A672 specification

Table 1

Materials and Manufacture

Table 2

Chemical Composition & Mechanical Properties

Tensile test

Transverse tensile properties of the weld joint

Transverse Guided Weld Bend Tests

Radiographic Examination

Dimensions, Mass and Permissible Variations

Supplementary Requirement

Tension and Bend Tests

Charpy V-Norch Test (For pipe with nominal wall thickness of 1/2 inch and greater)

Hardness Test

Product Analysis

Metallography

Magnetic Particle Examination of Base Metal

Magnetic Particle Examination of Weld Metal

Liquid Penetrant Examination of Weld Metal

Straight Beam Ultrasonic Examination of Flat Plate-UT1

Straight Beam Ultrasonic Examination of Flat Plate-UT2

Angle-Beam Ultrasonic Examination (Plate less than 2 inch 50.8mm Thick)-UT3

Our Supply Range for ASTM A672 Pipe

Standard and Grades: ASTM A672 B60, B65, B70, C55, C60, C65, C70, A45, A50, A55, D70, D80, H75, H80, J80, J90, J100, L65, L70, L75, N75

Material types: EFW pipes for high temperature and moderate temperature

Manufacturing types: Electric Fusion Welded

Sizes: 16” to 60”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, up to 3 inch

Length: 6 meters, 12 meters or customized.

Surface treatment: Painted, Natural, 3PE, FBE

Ends: PE (Plain End), BE (Beveled Ends)