API 5CT P110 Casing and Tubing Pipe

Standards: API SPEC 5CT

Grades: P110, J55/K55, N80, L80, L80, L80 13Cr, T95, Q125

Stock Available: Yes

Manufacturing process: Seamless, ERW

Casing pipe dimension: 4-1/2” to 20”

Tubing dimension: 1.050” to 4-1/2”

Coupling thread: BTC, LTC, STC, premium connections threads, HYD, and equivalent.

Length: R1, R2, R3

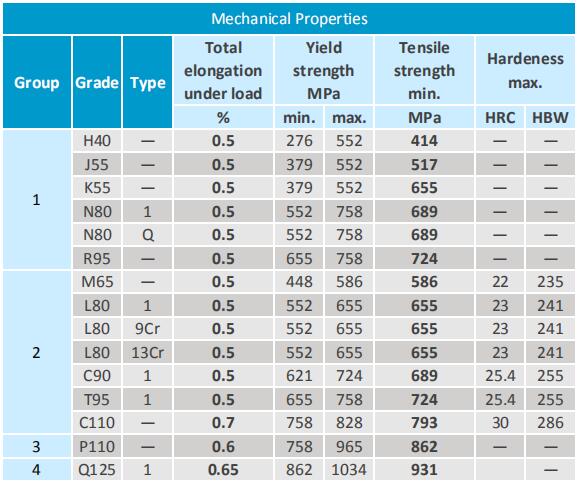

API 5CT P110 Casing and Tubing is a high grade than J55/K55, N80, L80 and T95, tensile strength minimum 862 Mpa, yield strength 758 to 965 Mpa. P110 casing ends with white band to specify this material, it is widely used for oil drilling and producing in a particular surroudings especially for a deep oil well.

API 5CT P110 Casing and Tubing stock

API 5CT P110 manufacturing types

P110 casing and tubing could be made by welded ERW or seamless and in most cases seamless type is adopted.

Heat treatment types for P110 pipes

P110 pipes shall be heat treated with full-body, full-length, as per API 5CT 10th edition quenched and tempered (simplified with Q) shall be adopted to the products. Normalized (N) or normalized and tempered (N&T) is not applicable for P110 casing and tubing.

Special chemical requirements for ERW P110 pipe are specified in Table E.4 in API 5CT, and other requirements specified in A.6 SR11.

Heat treatment is required for P110 grade,

Reference Inspection for P110 Casing and Tubing

Visual inspection for pipe surface

Dimension check

NDT test including Magnetic particle, Ultrasonic Test, Hydrostatic Test

Drift test

Chemical analysis

Mechanical test on tensile strength, yield strength and elongation

Charpy impact test

Flattening tests

Hardness test

Thread ends check with thread gauge and coupling check

API 5CT P110 Casing:

P110 Casing is installed downhole to provide structural integrity to the wellbore and must withstand external-collapse pressure from rock formations and internal-yield pressure from fluid and gas. It needs to bear its own weight and withstand the torque and transaxial pressure placed on it while running downhole. Casing is considered as a pipe pile that will stabilize the oil well.

API 5CT P110 Tubing:

P110 Tubing is installed inside the casing. It is used to transport (pump) crude oil or natural gas from the source rock to the ground wellhead. Inside tubing is sucker rods, where used for pumping oil and gas.

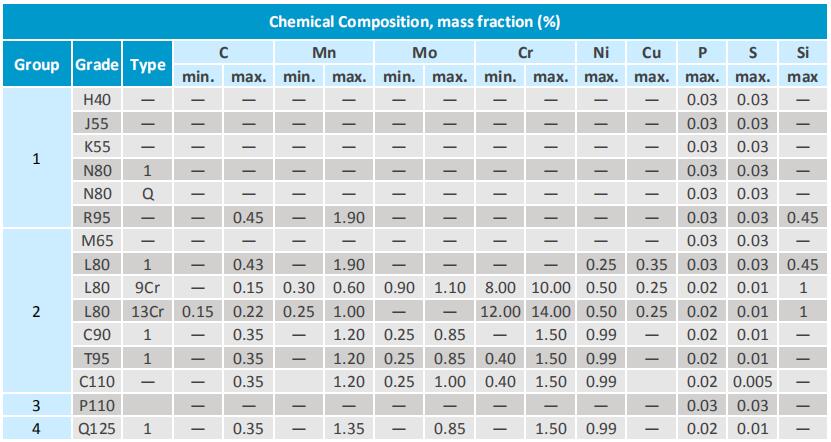

Chemical Composition

For seamless P110 pipe, only limits phosphorus and sulfer content 0.03%, and in case welded type, maximum P 0.02% and S 0.01%. Other chemical composition like C, Si, Mn, Mo, Cr no limits.

Mechanical Properties

Connection type, ends and Couplings

Casing and tubing ends type are different where for casing usually BTC and tubing with EUE or NU.

P110 casing pipe connection types

Common use connection BTC, buttress thread marked with BC

LC: Long round thread

SC: Short round thread

Premium connections like HYD, and other gas tight thread

Customized connection threads as per client requirement

P110 tubing connections with regulare and special clearance

EUE: External upset, tubing ends have an exeternal upset with a larger diameter and thickness than tubing body

NU: Non upset, tubing ends same diameter and thickness with tubing body

Dimension and tolerances

Length Range:

R1: 4.88 to 7.62 meters, permissible variation max 1.83 meters, and permissible length min 5.49 meters.

R2: 7.62 to 10.36 meters.

R3: 10.36 to 14.63 meters.

Outer diameter tolerance:

For pipes below 4-1/2 inch, tolerances +/- 0.79mm or 0.031 inch

For pipes equal and above 4-1/2 inch, tolerances +1% and -0.5% of pipe diameter

Wall thickness tolerance – 12.5%.

Imperfections:

Maximum permissible depth of linear imperfections, external and internal imperfections 12.5 of wall thickness. In case required 5% also could be adopted for P110 grade.

Octal supply range for P110 casing and tubing

Standards: API SPEC 5CT P110 Casing and Tubing

Grades: P110

Stock Available: Yes

Manufacturing process: Seamless, ERW

P110 Casing and Tubing Outer Diameter: 2-3/8”, 2-7/8”, 3-1/2”, 4-1/2”, 5-1/2”, 6-5/8”, 7”, 7-5/8”, 7-3/4”, 8-5/8”, 9-5/8”, 10-3/4”, 11-3/4”, 13-3/8”, 16”, 18-5/8”, 20”

Thickness: 4 LB/FT to 106.59 LB/FT, 0.244” to 0.875”

Coupling thread: BTC, Buttress (Regular, Special bevel or special clearance), LTC, STC, premium connections threads.

Length: R1, R2, R3, customized