ASTM A234 WP11 Pipe Fittings Specification

Grades in Chrome Moly Alloy Steel: ASTM A234 WP11 CL1/2/3, WP12 CL1/3, WP5 CL1/3, WP9 CL1/3, WP91 Type 1/2

Grades in Carbon Steel: ASTM A234 Grade WPB, WPC,

Outer Diameters: 1/2” to 48” in ASME B16.9

Wall Thickness Schedule: SCH 10, SCH 20, SCH 30, SCH 40, SCH STD, SCH 80, SCH XS, SCH120, SCH 160, SCH XXS comply with ASME B36.10

Pressure Class: Class 150, 300, 600, 900, 1500, 2500

Manufacturing Standards: ASME B16.9, ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97.

ASTM A234 WP11 (ASME SA234 WP11) is Chrome Moly Pipe Fittings standard specification for high temperature services. WP11 Pipe Fittings Chrome content at 1.00% to 1.50%, Moly content 0.44% to 0.65%, Minimum tensile strength 415MPa, minimum yield strength 205Mpa. It covers the butt-welded pipe fittings of Elbow, Tee, Reducer, Cap and Cross, and some socket welding, threaded pipe fittings, raw material from ASTM A335 P11.

ASTM A234 Standard Scope

The specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction covered by the latest revision of ASME B16.9, B16.11, MSS-SP-79 /83 /95 /97. These pipe fittings used in pressure pipelines and pressure vessel fabrication for servic at moderate and increased temperatures. Fittings out of above standards shall be complied with A960/A960M.

It does not cover cast welding fittings which refered standards are ASTM A216/A216M and A217/217M.

Corresponding Material

Seamless Pipe Standard: ASTM A335 P11 / ASME SA335 P11

Flange Standard: ASTM A182 F11

Steel Plate Standard: ASTM A387 Grade 11/ ASME SA387 Grade 11

Welded pipe standard: ASTM A691 1-1/4 CR

Key Elements – Chromium and Moly

Chromium is a key component that is used in the manufacture of stainless steel. If the chromium levels are above 12%, it can be classified as stainless steel. The oxidation resistance potential of chrome is irreplaceable even in elevated temperatures. The hardness, tensile and yield strength is better at standard temperatures. Due to the composition of the material, it is ideal to be used in power plants, refineries, petro-chemical plants and other oil field services when there is transportation under high temperatures and pressures involved.

Moly ensures that the material is more resistant to softening, restrains the growth of grains and lessens the chances of embrittlement. It is the single additive that is responsible for the increase in high temperature resistance (to 540-750°C) and it also improves the corrosion resistance to steel.

Materials and Manufacturing

The raw material for making ASTM A234 WP11 fittings hall be fully killed, consisting of forgings, bars, plates, sheet, and seamless or fusion-welded pipe products with filler metal added and shall conform to the chemical requirements of Table 1. Unless specified for carbon steel plates or sheet, the steel may be made to either coarse grain or fine grain practice. Which ASTM A234 WP9 shall be made to fine grain practice.

Forgings or forming operations could be perfomred by hammering, pressing, piercing, upseting, rolling, extruding, bending, fusion welding, machining, or by a combination of two or more above operations. Which the point of manufacturing is not to produce injurious imperfections in the fittings.

ASTM A234 WP11 Fittings Data Sheet

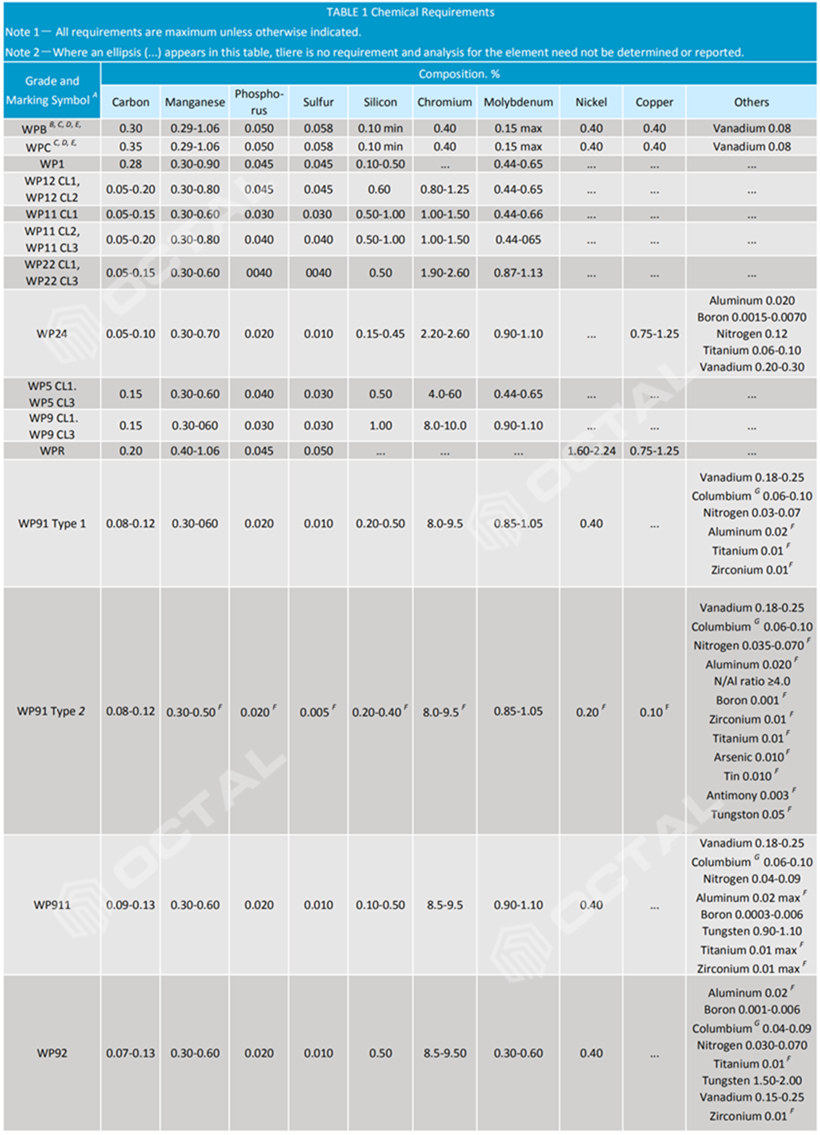

Chemical Composition:

Table 1

A When A234 fittings are made by welding structural, the grade and marking shown above shall be added letter “W”.

B Fittings made from steel plate or bar may require 0.35 max carbon.

C In case made from forgings may have 0.35 max carbon and 0.35 max silicon with no minimum.

D For each reduce of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted, up to a maximum of 1.65 %.

E Copper + Nickel + Chromium + Molybdenum shall not exceed 1.00 %.

F Applies both to heat and product analyses.

G Columbium (Cb) and Niobium (Nb) are alternate names for element 41 in the Periodic Table of the Elements.

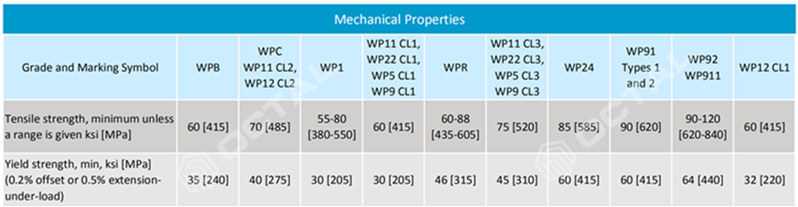

Mechanical Properties:

Table 2

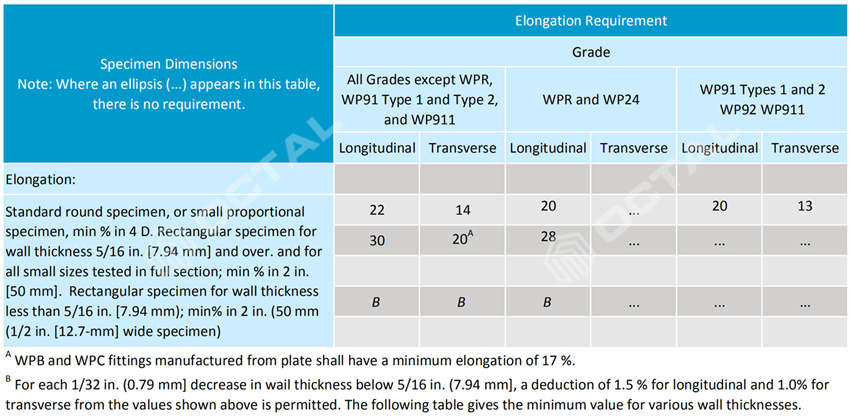

Elongation

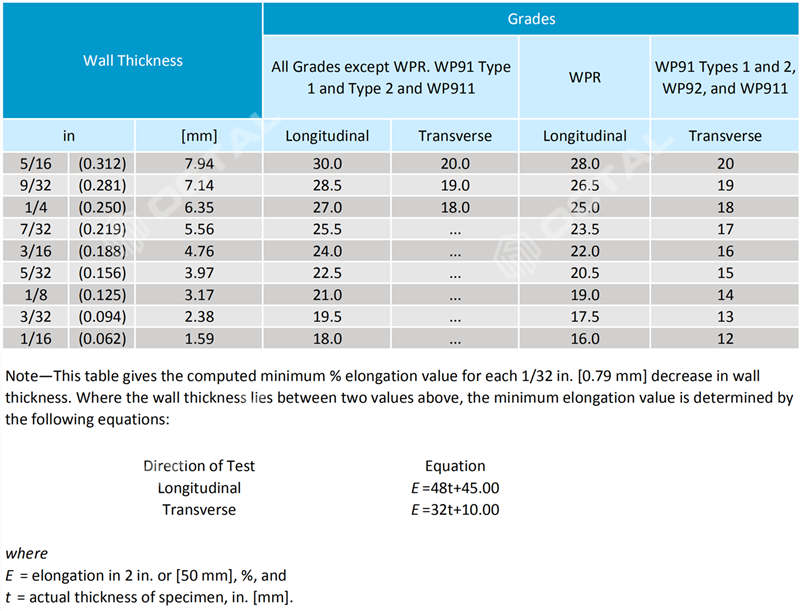

For different wall thickness Elongation Value:

Heat Treatment

For alloy material:

ASTM A234 WP11 (ASME SA234 WP11) fittings after shaping from an elevated temperature, shall be cooled down to a temperature below critical range under suitable conditions which preventing injurious defects caused by too rapid cooling, but in no case more rapidly than the cooling rate in still air. Referring standard in Section 7 of ASTM A960/A960M.

Fittings of grades WP11 Class 1, WP11 Class 2, WP11 Class 3, WP12 Class 1 & Class 2, WP22 Class 1 & 2, WP5, WP9 shall be furnished in the annealed, isothermal-annealed, or normalized and tempered condition.

In case of normalized and tempered, temperature for WP11 Class 1, WP11 Class 2, WP11 Class 3, WP12 Class 1 & 2, shall not be less than 1150℉ 620℃; For grades WP5, WP9, WP11 Class 1 & 3, the tempering temperature shall not be lss than 1250℉ 675℃.

For Carbon Steel Grades ASTM A234 WPB, WPC, WPR

Hot formed WPB, WPC, WPR fittings forming at above 620℃[1150℉] to 980℃[1800℉] no need to be heat treated which they are cooled in still air.

Hot formed or forged WPB, WPC, WPR fittins made at above 980℃[1800℉] shall be annealed, normalized, or normalized and tempered. NPS4 hot forged fittings no need to be heat treated.

Fittings over NPS12, produced by locally heating a portion of the fitting stock to any temperature for forming, shall be annealed, normalized, or normalized and tempered. And these fittings inlcudes elbow, tee, reducers, the carbon content shall les than 0.26%. NPS12 under no need to be heat treated under this forming process.

Cold formed fittings, below 620℃[1150℉], shall be normlized or stress relieved at 595 to 690℃[1100 to 1275℉].

Fittings produced by fusion welding and wall thickness at welded end of 3/4 in [19mm] or bigger shall be post-weld heat treated at 595 to 675℃[1100 to 1250℉].

At manufacturer’s option, heat treatment could be performed.

Hardness

A minimum of two pieces per batch or continuous run shall be hardness tested to ensure fittings of each grade comply with Table 2. Except only one fittings is pruchased and except Grade WP91 Type 1 and Type 2.

Fittings for ASTM A234 WP5, WP9 and WPR, 217 HBW maximum hardness.

Hyrdrostatic Tests

Shall be complied with ASTM A960/A960M.

Product Marking:

Shall be complied with ASTM A960/A960M.

Our Supply Range

Grades in Alloy Steel: ASTM A234 WP11 CL1/2/3, WP12 CL1/3, WP5 CL1/3, WP9 CL1/3, WP91 Type 1/2

Grades in Carbon Steel: ASTM A234 Grade WPB, WPC

Outer Diameters: 1/2” to 48” in ASME B16.9

Wall Thickness Schedule: SCH 10, SCH 20, SCH 30, SCH 40, SCH STD, SCH 80, SCH XS, SCH120, SCH 160, SCH XXS comply with ASME B36.10

Pressure Class: Class 150, 300, 600, 900, 1500, 2500

Manufacturing Standards: ASME B16.9, ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97.