API 5L X42 Pipe Specification

API 5L X42 welded (ERW, LSAW, SSAW) and seamless carbon steel line pipe, as following:

PSL1 or PSL2

Diameters: 1/2” to 60”

Wall thickness Schedule: SCH 10, SCH 40, SCH 80, to SCH 160

Coating 3PE, FBE, Black, Varnished

Length Range: 20 ft (6M), 40 ft (12M)

API 5L X42 pipe also called L290 pipe (by ISO 3183), named by minimum yield strength 42100 Psi or 290 Mpa. It’s a higher grade than Grade B where API 5L has various grades up to X100, so x42 pipe is an low-medium level, and it requires large quantities in most of pipelines for oil and gas transmissions.

Octal offers API 5L X42/L290 steel pipe in welded ERW and HFW, LSAW and seamless. Product Specification in PSL1 and PSL2, sizes from general 4”, 6”, 8”, 10”, 12”, 16”, 20” and up to 60 inch.

API 5L X42 Pipe Specification

The pipes ranges in PSL1, PSL2, Sour Services, for onshore and offshore.

API 5L X42 PSL1, in common delivery condition of As Rolled.

API 5L X42N/M/Q, for PSL2 pipe with delivery condition of N, M, and Q.

API 5L X42NS/MS/QS, used for sour services pipelines.

Suffix Letter Means

R: As rolled

N: Normalizing rolled, Normalized formed, Normalized

Q: Tempered and quenched

M: Thermomechanical rolled or thermomechanical formed

S: Sour Service

Ranges by Manufacturing Types

Seamless: Includes hot rolled seamless and cold drawn seamless, diameters up to 24 inch normally.

ERW: Electric Resistance Welded, OD up to 24 inch.

DSAW/SAW: Double Sub-merged Arck Welding, substitute welding methods than ERW for larger diameter welded pipes.

LSAW: Longitudinal Sub-merged Arc Welding, also called JCOE pipe, OD up to 56 inch. JCOE is named by manufacturing processes with J Shape, C shape, O shape and cold expanding process to release the pipe strength during transformations.

SSAW / HSAW: Spiral Sub-merged Arc Welding, or Helical SAW, diameters up to 100 inch

API 5L X42 chemical composition and mechanical strength

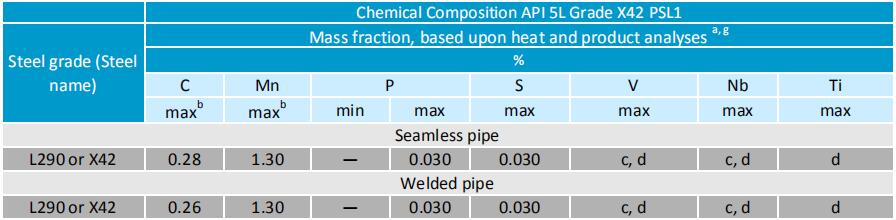

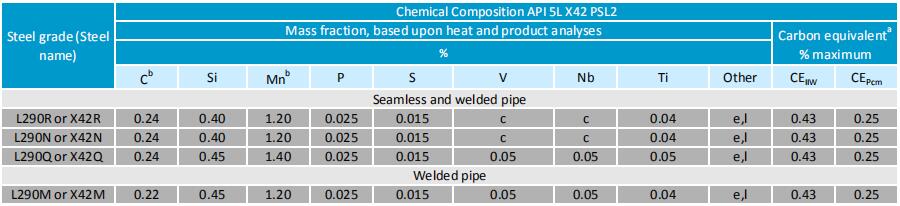

Chemical Composition

Chemical composition property is C≤0.28%, Mn≤1.3%, P≤0.030%, S≤0.030%, Nb+V ≤ 0.06%, V+Nb+Ti ≤ 0.15%, and the properties of chemical element Mn maximum more 0.1% than Grade B.

The maximum content of the chemicals for the welded steel line pipe is lower than seamless steel line pipe.

Above specifications for API 5L X42 is under the condition of PLS1, in case of API 5L X 42 PSL2, the chemical properties and tensile strength is more strictly than PSL1.

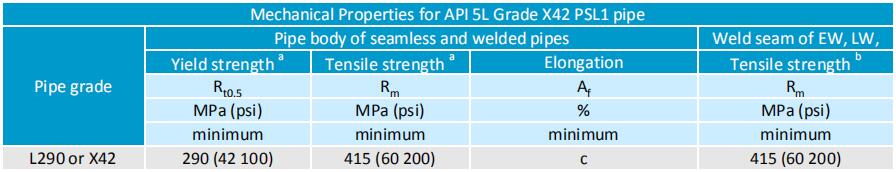

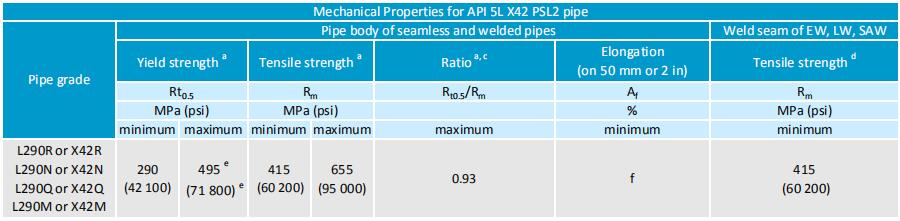

Yield strength and Tensile strength

API 5L X42 Min Yield Strength is 42100 Psi, 290 Mpa (As we called L290), Tensile Strength is the same with API 5L B 60200 Psi, 415 Mpa , Min Elongation: 21%. So compared to API 5L B steel line pipe, API 5L X42 steel pipe tensile strength is higher 6600 Psi, 45 Mpa.

a. For intermediate grades, the difference between the specified minimum tensile strength and minimum yield strength for the pipe body shall be as given in the table for the next higher grade.

b. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was

determined for the pipe body ung footnote a)

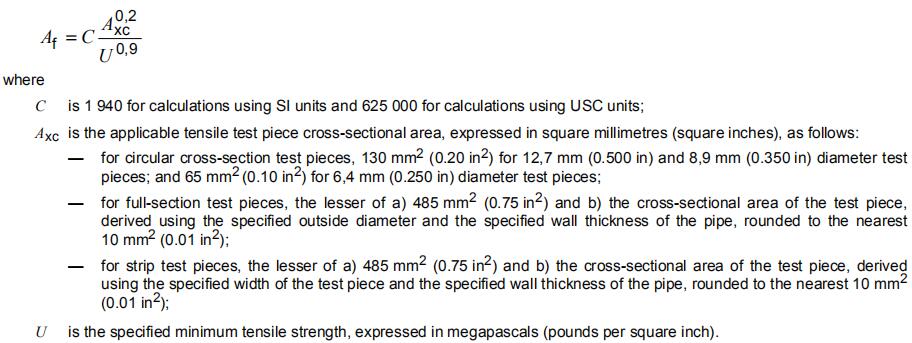

c. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be as

determined using the following equation:

a. For intermediate grades up to Grade L320 or X46, the tensile strength shall be ≤ 655 MPa (95 000 psi). For intermediate grades greater than Grade L320 or X46 and lower than Grade L555 or X80, the tensile strength shall be ≤ 760 MPa (110 200 psi).For intermediate grades higher than Grade L555 or X80, the maximum permissible tensile strength shall be obtained by interpolation. For SI units, the calculated value shall be rounded to the nearest 5 MPa. For USC units, the calculated value shall be rounded to the nearest 100 psi.

c. This limit applies for pipe with OD > 323.9 mm (12.750 in).

e. For pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 495 MPa (71 800 psi).

Other conditions same refers with PSL1.

Our supply range for API 5L X42 pipe

Grades: X42 or L290 (N,M,Q,R)

Product Specification Level: PSL1, PSL2

Manufacturing types: ERW, SAW, (LSAW, SSAW), SEAMLESS (SMLS)

Pipe Sizes: 1/2” to 40” (SEAMLESS), 1/2” to 24” (ERW), 16” to 60” (LSAW)

Steel Pipe Schedule (Wall thickness): SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, SCH XXS, SCH 120, SCH 160

Length range: Random length 5 to 12 meters, fixed length 20 ft (6 meter), 40 ft (12 meter)

Coating types: 3PE, FBE, black painting, varnished, Inside CRA clad or lined pipe

Ends type: Beveled and Plain

Ends protection: Plastic or iron steel caps

MTC types: EN 10204 3.1, EN 10240 3.2

Applications

Oil and gas transmission pipe;

Petroleum and natural gas industries;

Low and medium pressure pipeline systems;

Sour services (Low Carbon, CEQ, and S) Nace pipe anti-corrosion for H2S environment;

On shore and off shore pipelines;

Standard description for API 5L X42 PS1 and PSL2 pipe order

Item Brief Description:

LINE PIPE, SMLS, API 5L X42 PSL2, SOUR, Outer Diameter 16 IN , Wall Thickness 12.7 MM, 3PE 3 Layer PPE Coated

Item Spec:

Design Standard API 5L

Dimensional Spec ASME B36.10M

Material Carbon Steel

Material STD API SPEC 5L 45TH Edition

End Finish Beveled

End Protection Pipes Ends Shall Be Protected By Use of Suitable End Protectors.

Color Code As Per Manufacturer’s Standard

Surface Protection Shall Be Mill Coat/Varnished Based On Synthetic Resin for Instance ALKYD, URETHANE, EXPOXYESTER, ACRYLATES (From these different generic types)

Wall Thickness SCH 40, 12.7 MM

Service Sour

Service Requirements NACE MR-0175 or ISO 15156

Addtional Requirements (from client technical protocol)

Size Normal 16 in

Description Carbon Steel Line Pipe

Pipe Finish Seamless