Clad Pipe Fittings

CRA clad pipe fittings, including elbows, tees, reducers, and flanges, combine carbon steel strength with corrosion-resistant alloy protection for oil & gas pipelines.

Introduction

In pipeline systems where fluid corrosivity is high—such as sour gas, CO₂ injection, seawater reinjection, and chemical process streams—standard carbon steel pipe fittings often suffer from rapid metal loss and failure. Clad pipe fittings offer a robust solution by combining a corrosion-resistant alloy (CRA) layer or liner with a carbon steel base, thus marrying the structural strength of carbon steel with the corrosion protection of an alloy.

These fittings are essential complements to CRA clad and lined pipes, enabling complete corrosion-resistant networks while maintaining compatibility, performance, and lifecycle reliability.

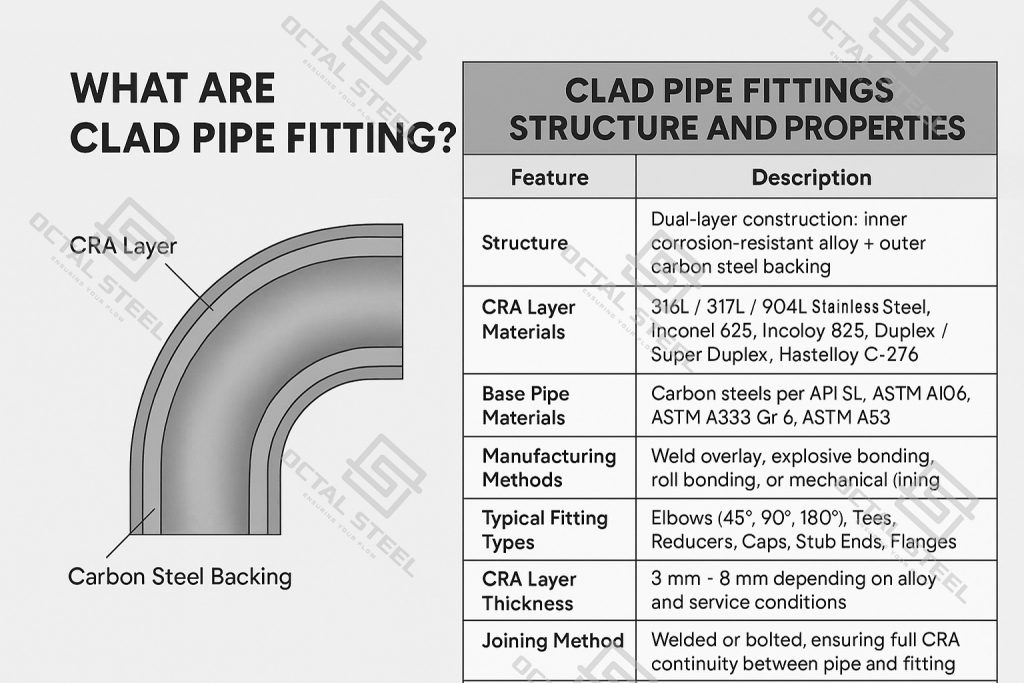

What Are Clad Pipe Fittings?

Clad pipe fittings are specialized components—such as elbows, tees, reducers, caps, and flanges—designed with the same clad or lined structure as CRA composite pipes. The outer (or inner) corrosion-resistant layer is metallurgically bonded or mechanically attached to a carbon steel backing material.

Construction Methods

- Weld Overlay Cladding: Alloy welding (e.g., stainless steel, nickel alloys) deposited on the fitting base.

- Explosive Bonding / Roll Bonding: Metallurgical bonding between alloy plate and carbon steel substrate.

- Mechanical Expansion / Insert Liners: Lined fittings where an alloy liner is expanded within a carbon steel body.

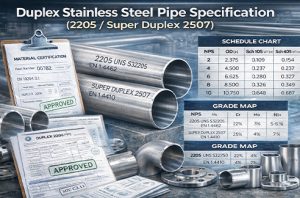

Typical Alloy Materials

- Stainless steels: 316L, 317L, 904L

- Nickel-based alloys: Inconel 625, Incoloy 825

- Duplex / Super Duplex stainless alloys

- Hastelloy, C-276, Alloy 22

The carbon steel backing usually matches pipe specifications (e.g., API 5L, ASTM A106, ASTM A333, etc.).

Clad Pipe Fittings Structure and Propertie

| Feature | Description |

| Structure | Dual-layer construction: inner corrosion-resistant alloy + outer carbon steel backing |

| CRA L | 316L / 317L / 904L Stainless Steel, Inconel 625, Incoloy 825, Duplex / Super Duplex, Hastelloy C-276 |

| Base Pipe Materials | Carbon steels per API 5L, ASTM A106, ASTM A333 Gr.6, ASTM A53 |

| Manufacturing Methods | Weld overlay, explosive bonding, roll bonding, or mechanical lining |

| Typical Fitting Types | Elbows (45°, 90°, 180°), Tees, Reducers, Caps, Stub Ends, Flanges |

| CRA Layer Thickness | 3 mm – 80 mm depending on alloy and service conditions |

| Joining Method | Welded or bolted, ensuring full CRA continuity between pipe and fitting |

| Performance Advantages | High corrosion resistance, pressure strength, long service life, and reduced maintenance |

| Typical Applications | Sour service pipelines, offshore platforms, refineries, chemical and desalination plants |

| Applicable Standards | ASTM A234 / ASME B16.9 (fittings), API 5LD / API 5L / ASME BPVC for materials |

| Testing & QC | NDT (UT, PT, RT), bond strength test, chemical & mechanical property verification |

Functionality & Benefits

- Seamless Corrosion Protection: The CRA layer provides resistance to corrosion, pitting, and sulfide stress cracking, while the carbon steel gives mechanical rigidity and cost efficiency.

- Uniform Performance: Ensures that corrosion resistance is continuous across pipeline and connection nodes (fittings), avoiding weak points.

- Structural Integrity: Fittings preserve high-pressure and structural requirements, especially in critical nodes subject to stresses such as bends, T-branches, and flange transitions.

- Reduced Maintenance & Longer Service Life: By protecting the high-risk fitting zones, operational downtime and replacement costs are minimized.

Applications

Clad pipe fittings are widely used in industries and environments such as:

- Oil & gas production and transport systems, especially sour service and CO₂ flooding pipelines

- Chemical and petrochemical processing plants

- Desalination, chlor-alkali, and aggressive brine handling processes

- Power generation systems, especially in salt-laden steam and cooling circuits

- Subsea flowlines and risers, where corrosion risk is high and joints must maintain integrity

Design & Manufacturing Considerations

- Compatibility: Fittings must match the pipe clad/liner alloy to avoid galvanic corrosion and differential corrosion rates.

- Bond Strength & NDT Verification: Clad layers must meet bond strength requirements; non-destructive testing (e.g., ultrasonic bond testing, dye penetrant) is essential.

- Weldability & Heat-Affected Zone: Care must be taken during joining (base-to-clad or clad-to-clad welds) to minimize dilution and preserve corrosion resistance.

- Thickness Design: The CRA layer should have sufficient thickness to last design life, considering erosion, corrosion allowance, and mechanical constraints.

- Dimensional Tolerances: Clad fittings must maintain close matching to pipe dimensions to allow smooth flow and sealing with gaskets or bolted joints.

Why Choose Octal Steel for Clad Pipe Fittings

- Integrated System Provider: We offer not only CRA clad and lined pipes, but also matching clad pipe fittings and flanges, enabling full-system compatibility.

- Quality Assurance: Every fitting is supplied with bond strength test reports, non-destructive examination (NDE), material certificates (MTC), and traceability documentation.

- Flexible Alloy Solutions: We support a broad range of CRA alloys (e.g., 316L, Inconel 625, duplex) and backing materials to tailor to project needs.

- Custom Capabilities: We design bespoke fittings (e.g. large-diameter elbows, multilayer clad tees) according to project specifications and constraints.

- Global Standards Compliance: Our fittings conform to API, ASME, ASTM, and other international standards, ensuring interoperability in global projects.