ASTM A335 P91 Pipe Specification (Chrome Moly Pipe)

Standard and Grades: ASTM A335 / ASME SA335 Grade P91

Material types: Chrome Moly Alloy

Manufacturing types: Seamless hot rolled

Sizes: 1/2” to 24” DN25 to DN600

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

Surface treatment: Polished, Varnished, 3LPE, FBE

Ends: PE (Plain End), BE (Beveled Ends)

ASTM A335 P91 / ASME SA335 P91 pipe is a seamless ferritic chrome-moly alloy steel pipe specifically designed for high-temperature service and corrosion resistance. Containing 8.00–9.50% chromium and 0.85–1.05% molybdenum, this alloy provides excellent creep strength, oxidation resistance, and long-term stability under elevated temperatures. With a minimum yield strength of 205 MPa and a tensile strength of 415 MPa, ASTM A335 P91 offers mechanical properties superior to conventional carbon steels, and it is often compared to ASTM A335 P9 pipe due to its similar alloying base but enhanced performance.

P91 material is part of a larger family of chrome moly steels used across multiple product forms:

-

ASTM A234 WP91 – seamless pipe fittings (elbows, tees, reducers)

-

ASTM A182 F91 – forged flanges

-

ASTM A387 Grade 91 – chrome moly alloy steel plates

-

ASTM A691 91 – welded chrome moly pipe fabricated from plates

By offering high toughness, wear resistance, and excellent weldability, ASTM A335 P91 pipe is widely applied in oil & gas pipelines, power plants, refineries, boilers, and petrochemical installations. Its unique combination of strength and metallurgical stability makes it indispensable for ultra-supercritical boilers, steam lines, and other critical high-pressure systems where long-term reliability is required.

Chrome Moly Pipe – ASTM A335 Pipe

ASTM A335 / ASME SA335 Pipe named chrome moly pipe as they have a high level of Chromium and Molybdenum.

Chromium will increase oxidation resistance and provides high-temperature strength, along with the better tensile & yield strength and proper hardness at room temperature. When the chromium content increased more than 12%, it can be classified as stainless steel.

Molybdenum increases the overall strength, resistance, elasticity, hardenability and overall quality, moly ensures that the material is more resistant to softening, restrains the growth of grains and lessens the chances of embrittlement. It is the single additive that is responsible for the increase in high temperature resistance (to 540-750°C) and it also improves the corrosion resistance to steel.

ASTM A335 P9/ASME SA355 P91 Data Sheet

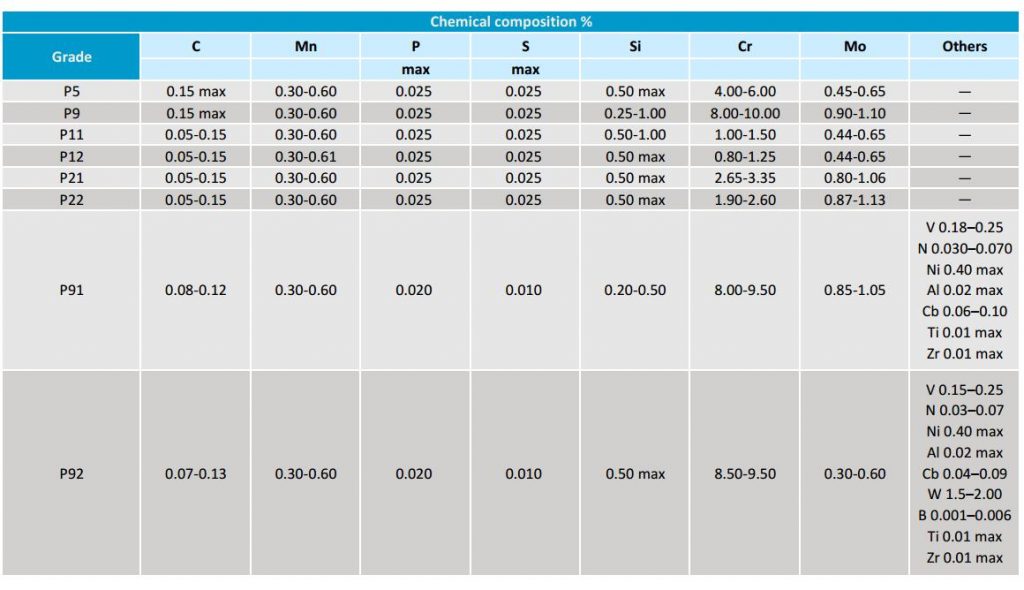

Chemical Composition and for other P grade Pipe (P5, P9, P11, P22)

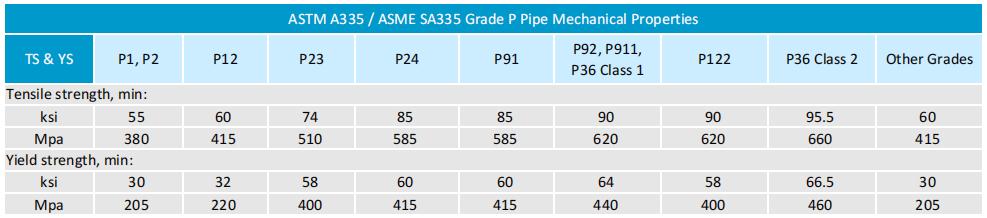

P91 Pipe Tensile Strength, Yield Strength

Elongation

Elongation in 2 in or 50mm or 4D minimum%:

For wall thickness 5/16 in [8mm] and over: Longitudinal 30% and Transverse 20%.

Elongation smaller 2 in or 50mm or 4D minimum%:

For wall thickness 5/16 in [8mm] and over: Longitudinal 22% and Transverse 14%.

For strip tests a deduction of each 0.8mm below 8mm shall be calculated with the Table 5 in ASTM A335.

Tolerances

Inside diameter not vary more than 1% from specified ID in the PO.

Outside diameter for 6mm to 40mm, vary +/-0.40mm.

For OD 40 to 100mm, +/-0.79mm.

OD 100 to 200mm, +1.59/-0.79mm.

OD 200 to 300, +2.38/-0.79mm.

Over 300mm 12 inch, +/-1% from specified OD in the PO.

Wall Thickness Tolerance

DN6 to 65, +20%/-12.5%

Abover DN65 t/D ≤5%A, +22.5%/-12.5%

Abover DN65 t/D >5%A, +22.5%/-12.5%

At= Specified Wall Thickness; D = Specified Outer Diameter

Referred standards of producing ASTM A335 P9 Pipe

a. ASTM A999/ A999M, Standard specification for common requirements for stainless and alloy steel pipe

b. ASTM A92, Hardness test methods for steel materials

c. E213, Instructions and practice for ultra sonic testing of steel pipe and tube

d. E309 Eddy-Current Examination methods for steel pipe products

e, E381, Inspection methods for steel bars, beams, profiles, billets and forgings.

f, E527, Numbering metals and alloys practices

g, E570, Instructions for flux leakage examination of ferromagnetic steel pipe products

Tests

Tensile tests: Transverse and Longitudinal

Flattening test

Hardness test not exceeding 250 HBW/265 HV30 [25HRC]

Bend Test shall be carried as per ASTM A370

Hydrostatic Test shall be carried , depending on the buyer a nondestructive examination shall be performed plus with hydrostatic test.

Heat Treatment

ASTM A335 P91 shall be heat treated with normalize and temper, or quench and temper, normalize temperature 1900-1975℉ [1040-1080℃], subcritical annealing or tempering temperature minimum or range 1350-1470 ℉ [730-800℃].

Our Supply Range

Standard and Grades: ASTM A335 / ASME SA335 Grade P9, P5, P1, P11, P22, P91

Material types: Chrome Moly Alloy

Manufacturing types: Seamless hot rolled

Sizes: 1/2” to 24”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

Surface treatment: Polished, Varnished, 3LPE, FBE

Ends: PE (Plain End), BE (Beveled Ends)