ASTM A333 Grade 6 Pipe

ASTM A333 Grade 6 pipe for low temperature services at above -45℃.

Sizes: 1/8” to 24”

WT Schedules: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 160, SCH XXS

Length: Single Random Length, Double Random Length, 20 ft, 40 ft

Ends Types: Plain, Beveled

Coatings: 3PE/3LPE, FBE, Galvanized, Varnished, CRA or stainless clad and lined

ASTM A333 Grade 6 pipe is common use material for low temperature services in above -45℃, with yield strength minimum at 240 Mpa, and tensile strength 415 Mpa. ASTM A333 Grade 6 pipe is often written in RFQs as ASTM A333 6 pipe, ASTM A333 Gr 6, or simply A333 ASTM. It is specified for low-temperature pressure service where notch toughness is verified by Charpy impact testing. In code projects, the common equivalent designation is ASME SA-333 Grade 6.

ASTM A333 Standard Specification Scope

ASTM A333 is the standard specification for seamless and welded steel pipe for application in low temperature services and other applications with the required notch toughness. In practice, the ASTM A333 Grade 6 specification is confirmed through a combination of chemical composition, mechanical properties, heat treatment condition, and impact test requirements. The required low-temperature performance should always be aligned with the project’s design minimum temperature and the specified impact test temperature.

Manufacturing Types

The standards includes manufacturing types in welding (ERW) and seamless. Material covers carbon and alloy steels.

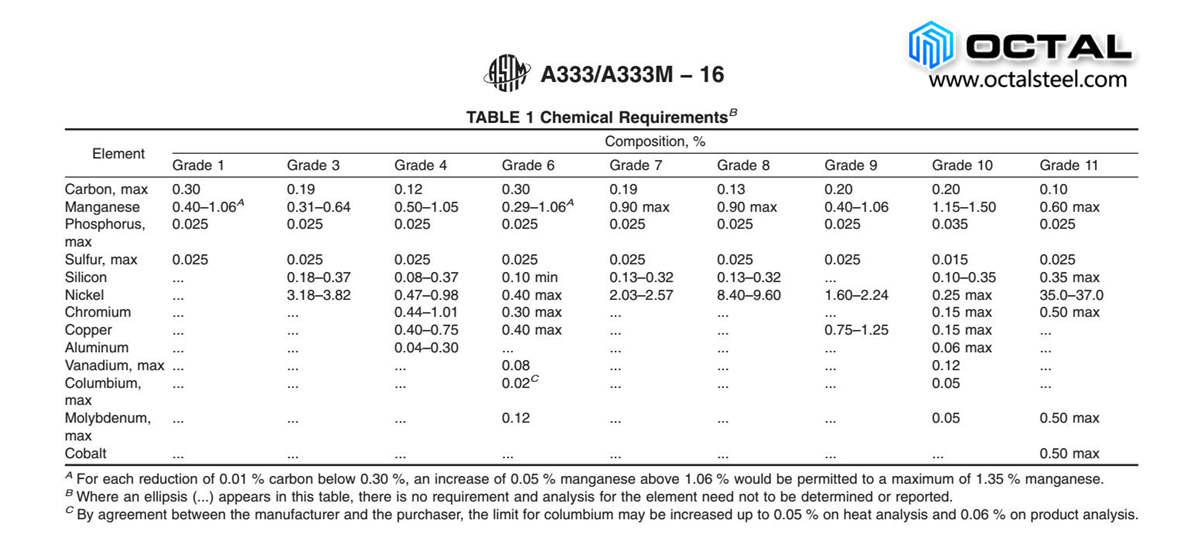

How many grades that included in ASTM A333 specificatoin?

There are total 9 grades in this standard, Grade 1, 3, 4, 6, 7, 8, 9, 10 and Grade 11.

There are differences on chemical composition and mechanical properties as following table:

A333 pipe Chemical Composition

Below is a text reference for ASTM A333 Gr 6 chemical composition (key elements), so the limits are readable and searchable alongside the chart.

| Item | ASTM A333 Gr 6 Chemical Composition | Limit |

|---|---|---|

| Carbon (C) | Max | 0.30% |

| Manganese (Mn) | Range | 0.29–1.06% |

| Phosphorus (P) | Max | 0.025% |

| Sulfur (S) | Max | 0.025% |

| Silicon (Si) | Min | 0.10% |

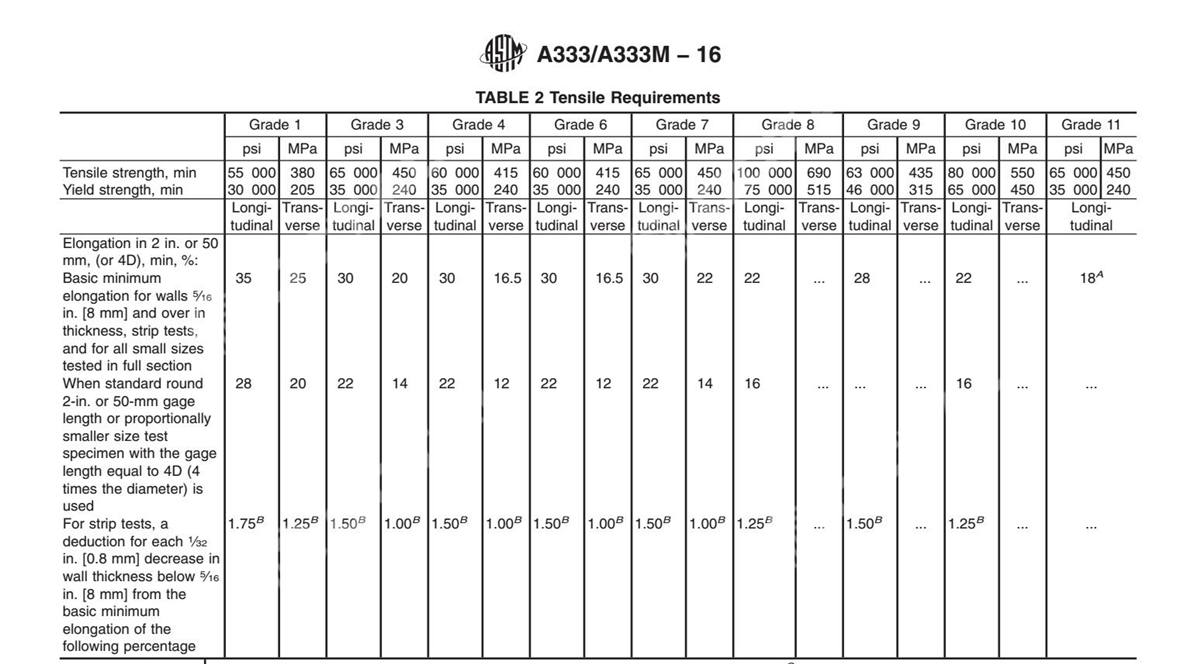

Yield Strength and Tensile Strength

For quick review of ASTM A333 Grade 6 material properties, the key minimum strength requirements are typically checked first during bid evaluation and incoming inspection.

| Property | ASTM A333 Grade 6 Requirement |

|---|---|

| Yield Strength (min) | 240 MPa (35 ksi) |

| Tensile Strength (min) | 415 MPa (60 ksi) |

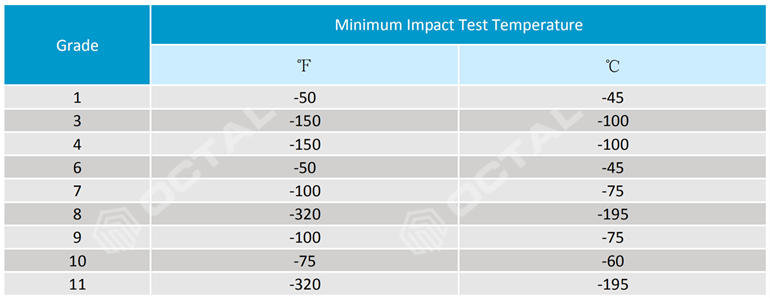

Impact Test Temperature

For low-temperature projects, the phrase “ASTM A333 temperature range” is usually interpreted as the specified impact test temperature and the design minimum temperature. ASTM A333 Grade 6 is commonly impact tested at −45°C (−50°F) unless the project specifies a different test temperature and acceptance criteria.

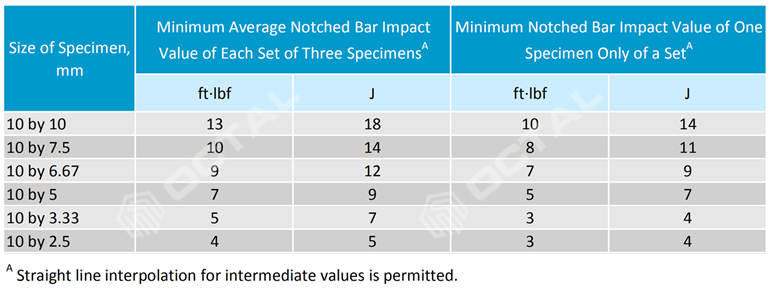

Impact Test Values For ASTM A333 Grade 6, 1, 3, 4, 7, 9, 10, 11

Dimensions and Sizes Schedule

The pipe complied to Nominal Dimension standard ASME B36.10M. (NPS or outside diameter and schedule number of average thicknes). Meanwhile, some pipe sizes may not be available under the ASTM A333 standard, as heavier wall thickness have an harmful on impact properties. In case client have special requirements shall follow the supplementary specification in ASTM A333. When ordering ASTM A333 pipe (including ASTM A333 6 pipe), list the required NPS/OD, wall thickness (or schedule), length (random or fixed), end preparation (plain, beveled, or threaded), heat treatment condition, and impact test requirement. Confirming these inputs upfront helps keep the ASTM A333 Grade 6 specification consistent across production, inspection, and site acceptance.

Related Standard for Producing ASTM A333 Grade 6 Pipe

Referred ASTM Documents:

a. ASTM A370 The test plan for the definitions for the mechanical strength test of the steel products

b. ASTM A999/ A999M The specification for the general requirements of stainless and alloy steel pipe

c. ASTM A671 The specification for ERW EFW steel pipe for lower temperature and atmospheric applications

d. E23 The test plan for notched bar impact testing for the iron and steel materials

e. E165 Practice for liquid penetrant examination for industry

f. E709 Guide for magnetic practice testing

Differences Between Each Grade

If you are comparing ASTM A333 Gr 1, Gr 3, and Gr 6, start from the project minimum temperature, required toughness, and material availability. Grade 6 is widely used as a general low-temperature carbon steel option, while other grades are selected when the service condition or alloy requirement is more specific.

As we know ASTM A333/A333M pipe could be manufactured in seamless or welded, so in which cases to use seamless type and when to use welded type?

In case of ASTM A333 Grade 4 steel pipe, it shall be made by the seamless process.

If welding process in EFW or ERW with filler metal added, and fabricated of pressure vessel quality plates.

| Item | ASTM A333 Gr 1 | ASTM A333 Gr 3 | ASTM A333 Gr 6 |

|---|---|---|---|

| Typical use (selection intent) | Low-temperature carbon steel pipe for cold-service piping where project toughness tests are required | Low-temperature service where chemistry/property requirements differ by grade and project preference | Most commonly specified grade for general low-temperature pressure piping with verified impact performance |

| Search terms buyers use | astm a333 gr 1 | astm a333 gr 3 | astm a333 gr 6 / astm a333 6 / astm a333 6 pipe |

| Why it is chosen (engineering focus) | Meets low-temperature service requirement with project-defined impact testing and weld-ability expectations | Used where grade selection is driven by project chemistry/property preference and availability | Balanced option for cold-service pipelines: availability + cost + toughness verification |

| Procurement checkpoint | Confirm test temperature, impact requirement, heat treatment, and MTC traceability to ASTM A333 | Confirm grade-specific chemistry/property requirements and required tests per project ITP | Confirm impact test temperature (commonly −45°C/−50°F unless specified), MTC, and dimensional schedule |

| Common documentation request | MTC + heat number traceability + impact test records (as specified) | MTC + chemistry/mechanical + impact test records (as specified) | MTC + impact test records + dimensional inspection + marking/traceability list |

ASTM A333 Pipe Heat Treatment Options

All the seamless and welded steel pipe, except ASTM A333 Grade 8 and Grade 11, shall be treated to control the micro-structure in one option as follows,

1. Normalized in a uniform temperature not less than 815℃ [1500℉], and cool in air or in the cooling chamber of an atmosphere controlled furnace, or after this heat treatment then heating to a suitable temperature to do the termpering.

2. Besides above heat treatment option, and with manufacturers will, reheat material to a suitable tempering temperature.

3. In case the seamless steel pipe in the ASTM A333, reheat and control hot working and the temperature of the hot finishing operation to a finishing temperature range from 845 to 945℃ [1550 to 1750℉], and cool in air or in a controlled atmosphere furance from an initial temperature more than 845℃ [1550℉]. For the ASTM A333 seamless steel pipe in Grade 1, Grade 6, and Grade 10 could be heat treated from a uniform temperature more than 815℃ [1500℉], then quenching in liquid and reaheat to a suitable tempering temperature, this type of heat treatment could replace the above plan also provided the ASTM A333 4.3.1. For the ASTM A333/ A333M Grade 8 and Grade 11, heating treatment shall be complied the standard specification.

For the ASTM A333 Grade 1, Grade 6 and Grade 10 steel pipe, and it is not allowed to add the chemical element not specified in the specification, but it is allowed to add the element for the deoxidation of steel.

Our Supply Ranges

• Standard: ASTM A333/A333M, ASME SA333

• Material Grades: Grade 1, Grade 3, Grade 4, Grade 6, Grade 7, Grade 7, Grade 8, Grade 9, Grade 10 and Grade 11

• Outer Diameters: NPS 1/8 inch to NPS 20 inch, 10.13mm to 1219mm

• Wall Thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, SCH XS to SCH160, SCHXXS; 1.24mm up to 1 inch, 25.4mm

• Range of Length: 20ft to 40ft, 5.8m to 11.8m, 6m to 12m.

• Ends procession: Plain, beveled, threaded

• Coatings: 3LPE, FBE, Galvanized

If you need an ASTM A333 Grade 6 pipe PDF for submittals, we can prepare a project-style data sheet together with traceable documentation such as MTC, heat numbers, dimensional inspection, and impact test records aligned to your ITP.

Why Choose Octal for ASTM A333 Grade 6 Pipe

Low-temperature service is unforgiving: what usually slows projects down isn’t the pipe body itself, but toughness proof + traceability. Octal supplies ASTM A333 Grade 6 pipe (ASTM A333 6 pipe / A333 ASTM) with a documentation-first workflow that aligns to EPC/owner review. Each order can be supported with an acceptance-ready pack that ties the pipe marking to the paperwork—typically including EN 10204 3.1 MTC (showing ASTM A333 Gr 6 chemical composition and mechanical results), Charpy impact test reports at the specified test temperature (often referenced as the “ASTM A333 temperature range” requirement), dimensional inspection records (OD/WT, length, straightness), and a heat/lot traceability list that maps heat numbers to pieces. Where the project calls for it, third-party inspection and release notes can be coordinated so the submittal is cleaner and needs fewer revisions. The end result is simpler: the offer matches the ASTM A333 pipe specification you issued, and the shipment arrives with the documents needed to pass receiving inspection without rework.