316L/316H/316Ti Stainless Steel Pipe

Standard: ASTM A312, ASME SA312, ASTM A269, ASTM A270

Common Use Grades: 316, 316L, 316H, 316Ti, 316N, 316LN

Diameters: From 1/8 inch to 30 inch.

Wall thickness: SCH 10S, 40S, 80S

Length: 20ft, 40ft, Single Random Length, Double Random Length and Customized

316L stainless steel pipe is a molybdenum-bearing austenitic stainless grade commonly purchased as ASTM A312 TP316L (UNS S31603) for corrosion-service piping where welded fabrication, traceable documentation, and repeatable inspection are part of acceptance. Within the same 316 family, 316H (UNS S31609) is selected for elevated-temperature design cases, while 316Ti (UNS S31635) is a stabilized option specified for prolonged high-temperature exposure. This page focuses on 316L stainless steel pipe and keeps the other 316 sub-grades as controlled alternatives.

Quick supply scope

Standards: ASTM A312 / ASME SA312; ASTM A269; ASTM A270

Common grades: 316L (focus), 316, 316H, 316Ti, 316N, 316LN

Diameters: 1/8 in to 30 in

Wall thickness: SCH 10S, 40S, 80S

Length: 20 ft, 40 ft, SRL, DRL, customized

Standards and matching components

Pipe standards

ASTM A312 / ASME SA312: common baseline for 316/316L/316H process pipe (seamless and welded)

ASTM A269: general stainless tubing used across instrumentation and utility systems

ASTM A270: sanitary tubing where hygienic acceptance language is specified

Matching components commonly specified with 316L systems

Stainless steel pipe fittings: ASTM A403 WP316/WP316L/WP316H

Stainless steel flanges / forgings: ASTM A182 F316/F316L/F316H

Stainless steel plates: ASTM A240 Type 316/316L/316H

EN/DIN references (by confirmation): EN X2CrNiMo17-12-2; DIN/EN 1.4404 commonly associated with 316L supply documentation

Seamless vs welded supply

316L stainless steel pipe can be supplied as seamless or welded. In purchasing, the practical differences usually show up in diameter availability, seam-related inspection scope, and how the project defines acceptance:

• Seamless pipe is often selected where a seam-free product is required by the project specification or where seamless availability matches the requested size and schedule.

• Welded pipe is widely used for larger diameters and schedule combinations where welded production is the practical route; seam acceptance is then managed through the specified NDE scope and traceable documentation.

For either route, approvals typically move faster when the purchase order defines the manufacturing route (seamless/welded), the inspection scope (if any beyond the base standard), and the document package format at the time of order.

316L vs 304/304L in corrosion service

Compared with 304/304L, 316/316L chemistry typically includes Mo 2.0–3.0% and Ni 10.0–14.0%, a combination widely associated with stronger resistance to localized corrosion mechanisms (pitting and crevice attack) in chloride-bearing environments. 316L is the low-carbon version within the 316 family and is commonly selected where welded fabrication and post-weld corrosion performance are evaluated as part of project acceptance.

Why Mo and Ni content drives the 316 vs 304 decision

Molybdenum and nickel are the two chemistry markers that most clearly separate the 316 family from 304 in practical purchasing decisions. 304/304L is essentially Mo-free, while 316/316L carries Mo 2.0–3.0%, a range commonly associated with improved resistance to localized corrosion mechanisms in chloride-bearing service—especially pitting and crevice attack. That difference becomes more relevant when the system includes stagnant zones, gasketed joints, threaded connections, dead legs, or intermittent salt contamination, where localized corrosion risk is typically more difficult to manage than uniform corrosion.

Nickel content also matters for 316/316L because Ni 10.0–14.0% stabilizes the austenitic structure and supports toughness and formability across a wide temperature band. In fabrication-heavy projects, that translates into more predictable forming and weld fabrication behavior, fewer fit-up surprises, and lower rework risk when spools and supports must hold tight alignment. For procurement, the Mo/Ni difference is not only a material label—it influences how confidently the project can treat corrosion risk at joints and crevices, which is often the limiting factor in chloride-exposed systems.

| Grade family | Mo (typical range) | Ni (typical range) | What it changes in service | Typical trigger to upgrade |

|---|---|---|---|---|

| 304 / 304L | ~0% | Lower than 316 family | Lower margin against chloride-driven pitting/crevice corrosion at joints and stagnant zones | Coastal exposure, wash-down salts, chloride-bearing media, gasketed/crevice-prone designs |

| 316 / 316L | 2.0–3.0% | 10.0–14.0% | Typically stronger resistance to localized chloride attack; more robust selection confidence for crevice-prone assemblies | When project corrosion margin is tight or maintenance access is limited |

Where 304/304L may still be acceptable

304/304L is commonly used when chloride exposure is controlled, crevice severity is low, and salt contamination or aggressive cleaning chemistry is not part of normal operation—provided the project specification allows it and joint/crevice corrosion is not the dominant risk.

When 316L may still not be enough

For higher-severity chloride duty, persistent stagnation, or more aggressive chemical exposure, selection may move beyond 316L to higher-alloy or duplex options based on the project’s corrosion basis and design code requirements.

Grade selection within the 316 family

316L (TP316L)

316L stainless steel pipe is commonly purchased as UNS S31603 and is frequently specified for welded corrosion-service piping where post-fabrication corrosion performance and documentation closure are key acceptance factors. It is routinely selected when the project wants the 316 family’s Mo-bearing corrosion resistance while keeping a low-carbon grade for welded assemblies.

316H (TP316H)

316H (UNS S31609) is typically specified when elevated-temperature strength is part of the design case and the grade is explicitly named in the project documents. It is used to align material selection with high-temperature performance requirements rather than general corrosion duty alone.

316Ti (TP316Ti)

316Ti (UNS S31635) is a stabilized grade option specified when prolonged high-temperature exposure is expected and stabilization language appears in the specification. It is also seen in heat exchangers and selected process equipment where stabilized-grade intent is documented.

316N / 316LN (TP316N / TP316LN)

Nitrogen-alloyed 316 variants are used when higher strength is required while maintaining austenitic corrosion performance. 316LN is commonly treated as the low-carbon + nitrogen-strengthened variant when both strength targets and welded-fabrication intent are present in the purchase specification.

| Grade | UNS | Primary intent | Typical decision trigger |

|---|---|---|---|

| 316L (TP316L) | S31603 | Corrosion service + welded fabrication | Low-C control for sensitization risk Mo-bearing chloride resistance |

| 316H (TP316H) | S31609 | Elevated-temperature strength | High-temperature design case / creep-driven selection |

| 316Ti (TP316Ti) | S31635 | Stabilized grade for prolonged high-temp exposure | Stabilization required by spec for sustained exposure |

| 316LN (TP316LN) | S31653 | Higher strength with corrosion resistance retained | Strength-driven design / wall optimization targets |

Ordering data and delivery

| Item | Options / Range | Notes |

|---|---|---|

| Standard | ASTM A312 / ASME SA312 ASTM A269 ASTM A270 |

Per project specification and purchase order |

| Common grades | 316 / 316L / 316H / 316Ti / 316N / 316LN | 316L (TP316L / UNS S31603) is the page focus |

| Diameters | 1/8 inch to 30 inch | Seamless or welded per size and availability |

| Wall thickness | SCH 10S / 40S / 80S | Other schedules by agreement |

| Length | 20 ft / 40 ft Single Random Length (SRL) Double Random Length (DRL) Customized |

Length tolerance and end condition per PO |

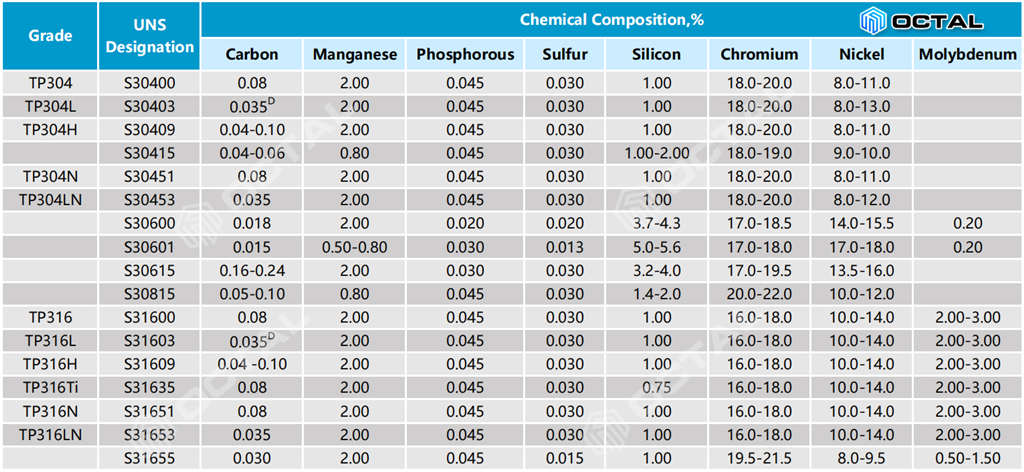

Chemistry snapshot

Reference chart for 304/316 families for comparison; TP316L (S31603) is the page focus.

| Grade | C (max) | Cr | Ni | Mo |

|---|---|---|---|---|

| TP316 | 0.08 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 |

| TP316L | 0.035 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 |

| TP316H | 0.04–0.10 | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 |

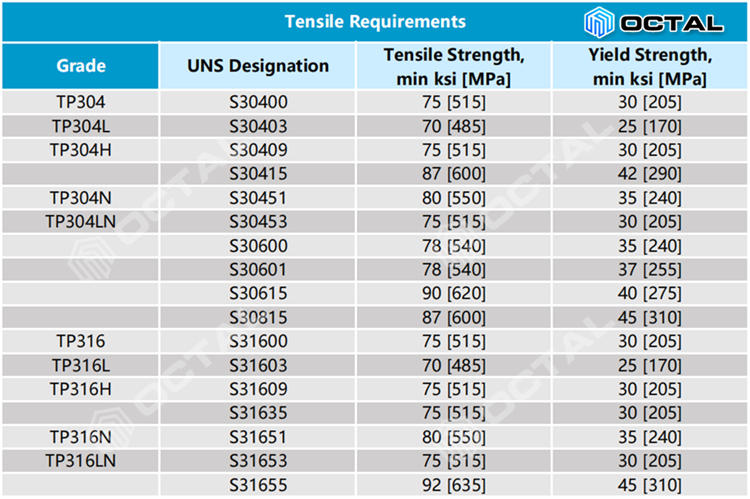

Tensile requirements

ASTM A312 TP316 316L 316H 316LN Mechnical Strength

Reference chart for common grades; verify minimum tensile and yield values against MTC and order requirements.

| Grade | UNS Designation | Tensile Strength (min) | Yield Strength (min) |

|---|---|---|---|

| TP316 | S31600 | 75 ksi [515 MPa] | 30 ksi [205 MPa] |

| TP316L | S31603 | 70 ksi [485 MPa] | 25 ksi [170 MPa] |

| TP316H | S31609 | 75 ksi [515 MPa] | 30 ksi [205 MPa] |

Quality and documentation

In corrosion-service stainless procurement, approvals close faster when documents, markings, and lot mapping connect each pipe length to heat/lot data and test records while keeping the inspection scope aligned to the purchase order.

| Acceptance element | Typical scope | Deliverable / evidence |

|---|---|---|

| Material identification | Grade + heat/lot traceability mapping to pipe lengths | Heat list + pipe-to-heat mapping (as applicable) |

| MTC package | Chemistry + mechanical results per standard | EN 10204 3.1 MTC |

| Dimensional & visual | OD, WT, length, straightness, end condition | Inspection record + packing list alignment |

| NDE (order-driven) | Weld seam RT/UT or other NDE where specified | NDE report package + traceable identification |

| PMI (if required) | PMI method and sampling plan per PO | PMI record (heat/lot referenced) |

| Marking & packing | Grade, size, schedule, standard, heat no. | Marking photos + packing list + seaworthy packing record |

Applications

316L stainless steel pipe is widely specified in systems where chloride-bearing media, cleaning chemicals, or mildly acidic environments increase pitting/crevice corrosion risk and where welded assemblies need stable post-fabrication corrosion behavior. Typical applications include:

• Marine and coastal utilities (salt exposure, splash-zone-adjacent service, seawater auxiliary and washdown-related lines where specified)

• Chemical and petrochemical process piping (transfer and circulation runs, chemical dosing/injection lines, corrosion-controlled utilities)

• Pharmaceutical and clean utilities (process/utility lines with controlled material identification, documentation-managed receiving, and defined surface condition language)

• Water and wastewater treatment (chloride-influenced plant piping, chemical feed lines, process and utility runs with corrosion margin evaluation)

• Architectural and structural components in corrosive environments (handrails, poles, supports, coastal infrastructure where aesthetics and corrosion resistance are both required)

Supply experience

Octal Steel supports 316L stainless steel pipe procurement with a shipment setup that reduces receiving-side ambiguity: each lot is kept segregated, each pipe is marked to match the heat/lot reference, and the packing list is built so inspectors can reconcile piece/heat/size/schedule without rework. Documentation is compiled as a single, traceable package—EN 10204 3.1 MTC, heat list, and (when ordered) PMI/NDE records—so the material review can be closed against the PO and project specification in one pass.

On the physical delivery side, Octal controls the points that most often trigger NCRs in stainless pipe receiving: end protection, clear bundle/box identification, and seaworthy packing that maintains marking readability through transit. For projects buying multiple grades or mixed schedules, lots are separated and labeled to prevent cross-mixing at site and to keep the receiving checklist aligned to the actual shipment content.

FAQ

Q1: What is the correct purchase description for 316L stainless steel pipe?

A1: A common line item is “ASTM A312 TP316L, UNS S31603, NPS/OD × Schedule, length (20 ft/40 ft/SRL/DRL), ends (PE/BE), seamless or welded, EN 10204 3.1 MTC.”

Q2: Why is 316L preferred for welded piping in chloride-prone service?

A2: 316L keeps Mo-bearing corrosion resistance for pitting/crevice control and limits carbon to reduce sensitization risk in welded fabrication, helping corrosion performance remain consistent after joining.

Q3: When should 316H be specified instead of 316L?

A3: Specify 316H when elevated-temperature strength is required by the design case or project specification; it is commonly tied to high-temperature service criteria rather than general corrosion duty.

Q4: What acceptance documents are typically required for 316L stainless steel pipe shipments?

A4: Common packages include EN 10204 3.1 MTC, heat/lot traceability aligned to pipe markings, dimensional inspection records, and any ordered NDE/PMI reports for the supplied manufacturing route.