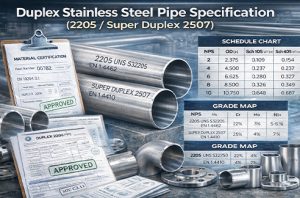

Duplex 2205 Stainless Steel pipe

Standards & Grade focus: ASTM/ASME A790; Duplex 2205 stainless steel pipe (UNS S32205/S31803); 2507 (UNS S32750, upgrade option)

Product focus:2205 duplex stainless steel pipe / duplex 2205 stainless steel pipe (pipe supply; fittings packaged when ordered)

Manufacturing route: Seamless or welded (as ordered)

Size range: NPS 1/2″–24″ (common)

Schedule: 5S / 10S / 40S / 80S (ASME B36.19M)

Ends: PE / BE (threaded as ordered)

Acceptance & docs: EN 10204 3.1 MTC + heat/lot traceability list; PMI/NDT/testing per PO/ITP when specified

Duplex 2205 stainless steel pipe is typically selected when chloride-bearing media, crevice-prone interfaces, and SCC risk need a stronger corrosion-and-strength balance than common austenitic stainless. In purchasing terms, 2205 duplex stainless steel pipe is defined by UNS designation and heat-treatment condition, then closed out through MTC review and traceability reconciliation at receiving. Super duplex 2507 is kept here as an upgrade path for higher chloride severity, but this page is built around duplex 2205 pipe scope and deliverables.

What duplex 2205 stainless steel pipe means in purchasing

In purchasing language, duplex 2205 stainless steel pipe is treated as a grade-locked scope defined by UNS designation and heat treatment condition, then verified through MTC review and receiving traceability reconciliation. For 2205 duplex stainless steel pipe, acceptance typically closes when chemistry and minimum mechanical baselines align to the MTC, and markings/packing list/heat-lot mapping remain consistent through delivery, cutting, and fabrication staging.

Where duplex 2205 stainless steel pipe is specified

2205 duplex stainless steel pipe is widely specified in high-pressure and highly corrosive environments where chloride exposure, crevice conditions, and stress corrosion cracking risk are evaluated together. Typical application scopes include:

• Chemical processing, transport and storage: pressure vessels, tanks, piping, and heat exchangers

• Oil and gas exploration and processing equipment: piping, tubing, and heat exchangers

• Marine and other high-chloride environments

• Effluent scrubbing systems

• Pulp and paper: digesters, bleaching equipment, and stock-handling systems

• Cargo tanks for ships and trucks

• Food processing equipment

• Biofuels plants

Most purchased duplex stainless steel grade families

Duplex 2205 stainless steel pipe

• Typical UNS: S32205 / S31803

• Common RFQ naming: 2205 duplex stainless steel pipe, duplex 2205 stainless steel pipe, duplex 2205 pipe, 2205 duplex pipe

• Shorthand chemistry used by many project teams: ~22% Cr, ~3% Mo, ~5–6% Ni, with N supporting corrosion resistance and phase balance

• In Octal deliveries, duplex 2205 stainless steel pipe is grade-locked by UNS/EN designation and maintained across pipe markings, packing lists, and certificate mapping so receiving can reconcile heat/lot identity without rework loops

Super duplex 2507

• Typical UNS: S32750

• Common RFQ naming: super duplex pipe, super duplex 2507 pipe

• Shorthand chemistry: ~25% Cr, ~4% Mo, ~7% Ni, used where the corrosion basis demands more pitting/crevice margin than duplex 2205 class intent

Duplex 2205 stainless steel pipe vs 2507 in real project execution

In mixed-grade MTOs, 2205 duplex stainless steel pipe commonly covers seawater utilities and many process circuits where corrosion margin remains inside the grade’s intended window, while 2507 is assigned to zones where gasketed interfaces, deposits, stagnation, and warmer seawater compress localized-corrosion margin. The procurement control point is typically the interface chain: ensuring pipe grade and fittings grade remain aligned as one auditable package.

Key chemistry baseline for duplex 2205 stainless steel pipe

Use this table for MTC first-pass screening and heat/lot reconciliation during receiving. The chemistry ranges below are commonly used to review 2205 duplex stainless steel pipe MTCs, distinguishing ordering language for S31803 and S32205.

| Grade | UNS | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|---|

| 2205 | S31803 | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 0.02 max | 21.0–23.0 | 2.5–3.5 | 4.5–6.5 | 0.08–0.20 |

| 2205 | S32205 | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 0.02 max | 22.0–23.0 | 3.0–3.5 | 4.5–6.5 | 0.14–0.20 |

Why chromium, molybdenum, and nitrogen matter for duplex 2205 stainless steel pipe

For practical purchasing, duplex 2205 stainless steel pipe is often summarized as a ~22% chromium duplex with molybdenum and nitrogen supporting pitting/crevice resistance and phase balance. That chemistry is one reason 2205 duplex stainless steel pipe is specified in chloride-bearing duty where joint severity and crevice geometry are harder to control than uniform corrosion. In many environments, duplex 2205 stainless steel pipe is specified as a step up from 316/316L when chloride-driven localized corrosion and stress corrosion cracking concerns become more prominent.

How duplex chemistry is commonly described in project specs

Duplex grades are typically written with high chromium, molybdenum, nitrogen additions, and lower nickel than austenitic stainless, because those are the elements project teams track when chloride pitting/crevice resistance and stress corrosion cracking risk are part of the corrosion basis.

In purchasing language, this chemistry is why duplex 2205 stainless steel pipe is frequently specified where chloride exposure is real and interfaces are crevice-prone, while also delivering higher yield strength than standard austenitics.

Mechanical properties baseline for duplex 2205 stainless steel pipe

Use this baseline to confirm minimum tensile/yield values before dimensional checks and release to fabrication.

| Grade | Tensile Strength (min) | Yield Strength 0.2% (min) | Elongation (min) | Hardness (HB) (max) |

|---|---|---|---|---|

| 2205 | 90 ksi | 65 ksi | 25% | 217 |

Physical properties snapshot for duplex 2205 stainless steel pipe

These values support thermal/electrical estimating and help interpret how properties shift with temperature.

| Temperature | Density (lbm/in3) | Electrical Resistivity (mW·in) | Thermal Conductivity (BTU/hr·ft·°F) | Heat Capacity (BTU/lbm·°F) | Electrical Resistivity (in x 10^-6) |

|---|---|---|---|---|---|

| 68°F | 0.278 | 27.6 | 8.7 | 0.112 | 33.5 |

| 212°F | — | 26.1 | 9.2 | 0.119 | 35.4 |

| 392°F | — | 25.4 | 9.8 | 0.127 | 37.4 |

| 572°F | — | 24.9 | 10.4 | 0.134 | 39.4 |

Corrosion and temperature envelope

Duplex 2205 stainless steel pipe is widely associated with strong resistance in chloride service, including improved resistance to chloride stress corrosion cracking compared with common austenitics in many environments. Duplex grades are commonly limited for sustained elevated-temperature service compared with austenitics; toughness can drop due to metallurgical changes at higher temperatures, and grade/application limits are typically set by code and project basis.

Welding, heat treatment, and processing notes

Welding characteristics

Duplex 2205 stainless steel pipe is commonly treated as weldable with procedures written to preserve corrosion performance through weld metal and HAZ. For 2205 duplex stainless steel pipe fabrication, filler-metal selection and heat input control are typically used to avoid excessive ferrite and to maintain intended joint performance where crevice severity is highest.

Heat treatment baseline

Duplex 2205 stainless steel pipe is commonly associated with an annealing temperature range of 1868 to 2012°F (1020 to 1100°C). 2205 duplex stainless steel pipe is not hardened by heat treatment, but it does work-harden, which affects forming and machining planning—especially on heavier schedules.

Forming and machining

2205 duplex stainless steel pipe can be formed, but higher strength increases spring-back and raises forming loads compared with many austenitics. Duplex 2205 stainless steel pipe is also typically more difficult to machine than 300-series austenitic stainless; rigid setups, minimized tool extension, and cutting sequences that remove work-hardened layers support dimensional control.

Duplex 2205 stainless steel pipe specifications that reviewers approve faster

A duplex 2205 stainless steel pipe definition closes reviews faster when it includes the standard basis, grade/condition, and acceptance evidence tied to the shipment.

Typical purchase definition fields

• Standard + manufacturing route (seamless or welded) for duplex 2205 stainless steel pipe

• Grade: UNS S32205 or S31803 (as ordered)

• NPS/OD, schedule, length, ends, quantity, tolerances

• Acceptance evidence: EN 10204 3.1 MTC + heat/lot traceability list

• PMI reports when ordered; NDE records for welded pipe when specified

Duplex stainless steel pipe schedule chart (common NPS sizes)

| NPS | OD (in) | Sch 10S WT (in) | Sch 40S WT (in) | Sch 80S WT (in) |

|---|---|---|---|---|

| 2 | 2.375 | 0.109 | 0.154 | 0.218 |

| 4 | 4.500 | 0.120 | 0.237 | 0.337 |

| 6 | 6.625 | 0.134 | 0.280 | 0.432 |

| 8 | 8.625 | 0.148 | 0.322 | 0.500 |

| 10 | 10.750 | 0.165 | 0.365 | 0.594 |

| 12 | 12.750 | 0.180 | 0.406 | 0.687 |

Duplex stainless steel advantages and constraints

Advantages commonly specified

⒈ Higher yield strength versus standard austenitic stainless, supporting thickness optimization in some code-verified designs

⒉ Strong resistance profile in chloride environments, especially where stress corrosion cracking is a concern—one reason 2205 duplex stainless steel pipe is specified for seawater utilities and aggressive process lines

⒊ Lower nickel content than many austenitics, reducing exposure to nickel-driven surcharge swings for certain alloy families

Constraints that appear in real project scopes

• Fabrication and welding are typically controlled more tightly than 300-series stainless to preserve phase balance and corrosion performance in welds and HAZ

• Duplex is commonly limited for sustained elevated-temperature service compared with austenitics because toughness can drop due to metallurgical changes at higher temperatures (limits vary by code and project basis)

• Forming/machining can be more demanding than common austenitics, so dimensional discipline and documentation alignment become part of a smooth acceptance path for duplex 2205 stainless steel pipe

Typical operating conditions: how duplex 2205 vs duplex 2507 plays out in real purchasing

Example 1: Seawater / desalination (intake, outfall, SWRO utilities)

What the line typically sees

⒈ high chlorides plus crevice conditions at flanges, supports, clamps, and deposits

⒉ intermittent stagnation and biofouling, with cleaning episodes (chlorination/chemical cleaning)

⒊ temperature swings that can tighten localized corrosion margins

What usually drives the grade callout

⒈ Duplex 2205 pipe is commonly specified for seawater utility headers and many desalination support lines where the project corrosion margin and interface design are within the grade’s intended duty window.

⒉ Super duplex pipe (including super duplex 2507 pipe) is more frequently written where seawater is warmer/more aggressive, crevice exposure is unavoidable, or the project demands higher pitting/crevice resistance at gasketed interfaces.

Practical procurement impact and Octal delivery solution

⒈ Mixed scope is where delays start: correct pipe grade paired with non-matching fittings becomes an NCR driver at receiving and during fabrication.

⒉ Octal can supply grade-matched packages (pipe + duplex stainless steel pipe fittings / flanges where included) with clear lot segregation, marking consistency, and certificate mapping that keeps the pipe-to-fitting grade chain intact on first submission.

⒊ For duplex 2507 scopes, Octal can package super duplex pipe fittings with the same traceability structure as the pipe to avoid “fittings-only” approval delays.

Example 2: Sour/acidic service and chemically aggressive media (H₂S / CO₂ / chlorides)

What the line typically sees

⒈ combined mechanisms (chlorides + acidity + localized corrosion risk), often with strict QA expectations

⒉ acceptance that depends on documented heat treatment condition, PMI coverage, and NDT scope (where specified)

What usually drives the grade callout

⒈ The scope is commonly governed by project requirements and qualification rules rather than generic material comparisons.

⒉ In these services, the “grade” is only one part of the purchase definition; the acceptance package (heat treatment condition, PMI/NDT/test records) becomes equally load-bearing for approval.

Practical procurement impact and Octal delivery solution

⒈ RFQ cycles often expand when the duplex scope lacks a clear record list or when welded vs seamless expectations are not aligned in the same submission.

⒉ Octal can deliver a single inspection dossier mapped to heat numbers and item IDs, including MTC, PMI records (as ordered), NDT/test records where specified, and lot-level traceability for pipe and fittings—reducing resubmittal loops and QA hold time.

⒊ End condition control and durable marking support traceability after cutting and beveling, reducing “unknown heat” hold points during spooling.

Example 3: High flow velocity, erosion–corrosion exposure, and rack weight constraints

What the line typically sees

• higher velocities (cooling water returns, abrasive wash circuits) where elbows/reducers see the earliest wear

• pipe racks where weight and support spacing matter, and strength-to-wall ratio can influence design thickness selection

What usually drives the grade callout

• Duplex is often selected for its strength and chloride resistance combination, while the highest damage risk concentrates at fittings and flow-disturbance locations.

Practical procurement impact and Octal delivery solution

• Fittings become the reliability limiter: elbows/tees/reducers carry the highest turbulence and crevice exposure and often receive the highest scrutiny.

• Octal can manufacture and/or supply duplex fittings lots with grade alignment, traceability linkage, and dimensional/marking consistency, so fabrication and QA do not stall on mismatched fittings or incomplete lot identity.

• Where projects split grades by area (duplex 2205 in utilities, duplex 2507 in higher chloride severity), Octal keeps segregation explicit in packing lists and dossier structure to prevent cross-issue during receiving and spooling.

Duplex pipe fittings and grade-matched packages

Even when the line item is 2205 duplex stainless steel pipe, interfaces are where localized corrosion and receiving NCRs concentrate. Grade-matched packages keep the pipe-to-fitting grade chain auditable on mixed shipments and reduce cross-mixing risk when multiple grades and schedules arrive together.

• Fittings supplied in the same grade family as the pipe, with marking/traceability carried through delivered lots

• Certificate mapping keeping fittings lots aligned with pipe heat/lot structure where required

• Mixed-grade scopes separated cleanly (for example duplex 2205 fittings for utilities, 2507 fittings for higher chloride severity areas)

• For marine/seawater duty where 2507 is specified, super duplex fittings packaged with the same acceptance record structure to avoid fittings-only approval delays

Octal supply scope for duplex 2205 stainless steel pipe

Duplex packages slip for repeatable reasons: mixed-grade receiving, missing traceability links, and document sets that arrive as scattered files and trigger repeated review cycles. Octal structures duplex 2205 stainless steel pipe supply so the shipment is reviewable, receivable, and auditable as one closed loop.

• Scope that stays together (pipe + grade-matched interfaces)

When the MTO includes both duplex 2205 stainless steel pipe and grade-matched fittings, Octal can ship them under one boundary while keeping lot segregation and item mapping clear. Each line item is mapped to its heat/lot list so QA can reconcile “what was ordered vs what arrived” without opening a second clarification loop.

• Controls that protect acceptance at receiving

Octal focuses on the failure points that generate NCRs on duplex deliveries: marking readability, end protection, and packing that prevents cross-mixing during transport and yard storage. Lot-separated packing lists and stable identification allow receiving teams to confirm grade, size/schedule, and quantity before materials are released to fabrication.

• Manufacture-linked documentation built as one dossier

Instead of separate attachments, Octal compiles the MTC package around the actual shipment: EN 10204 3.1 certificates tied to heat numbers and item IDs, plus the heat/lot traceability list arranged in the same structure as the PO line items. This reduces re-submissions caused by missing links between certificates, markings, and packing lists.

• Verification evidence when the PO requires it

When specified, Octal provides PMI records, required NDT/test records, and dimensional evidence aligned to the purchase definition and ITP, so reviewers can close the acceptance checks against the PO requirements rather than requesting “extra” evidence after the shipment is already on site.