Inconel 625 Pipe (Alloy 625 Pipe): Seamless vs Welded, Sizes, Schedule Chart, Suppliers & Price Factors

• Inconel 625 pipe (Alloy 625 pipe / 625pipe) overview for buyers: selection, sizing, and acceptance focus

• Seamless vs welded: how to choose based on service criticality and inspection scope

• Inconel 625 pipe sizes and a practical Inconel 625 pipe schedule chart reference

• Fittings & flanges compatibility: how to avoid interface and documentation mismatches

• Supplier qualification and Inconel 625 pipe price drivers for like-for-like RFQ comparison

Inconel 625 pipe (Alloy 625 pipe / 625pipe) is a nickel alloy pipe used where corrosion resistance and strength must hold up in aggressive media, high temperature, or high-cycle service. It is commonly purchased as Inconel 625 seamless pipe for critical duty, and as Inconel 625 welded pipes for certain sizes and project constraints when the inspection scope matches the job.

What this guide covers: product forms, seamless vs welded selection, Inconel 625 pipe sizes, a practical Inconel 625 pipe schedule chart reference, fittings/flanges compatibility, supplier qualification, and the key drivers behind Inconel 625 pipe price.

What is Inconel 625 Pipe (Alloy 625 Pipe)?

Inconel 625 pipe (often searched as alloy 625 pipe, inconel 625 pipes, or even “inconel 625 pipe”) refers to pipe made from UNS N06625-type nickel alloy designed for demanding corrosion and temperature environments. The buying decision is rarely about the alloy name alone—projects typically hinge on:

• Product form (pipe vs tube)

• Manufacturing route (Inconel 625 seamless pipe vs Inconel 625 welded pipes)

• Size expression (NPS + schedule vs OD + wall)

• Inspection and documentation required for acceptance

Product Forms: Inconel 625 Pipes & Tubes (What’s being quoted)

“Inconel 625 pipes & tubes” is a broad label. In practice:

• Pipe is normally specified by NPS and schedule (or by OD/WT if OD-driven).

• Tube is usually specified by OD + wall thickness and tighter tolerance requirements.

For mixed packages (pipe + tubes), consistency in marking, MTC format, and traceability list prevents receiving and stocking issues later—especially when multiple heats and lots arrive across split shipments.

Inconel 625 Seamless Pipe vs Welded Pipes

Inconel 625 seamless pipe is typically selected when projects prioritize conservative acceptance, fatigue exposure, higher pressure design margins, or owner preference for a fully seamless route.

Inconel 625 welded pipes can be practical for certain diameters and walls, but acceptance is often driven by weld seam control and the project’s NDT plan.

Seamless vs welded: selection at-a-glance

| Selection factor | Inconel 625 seamless pipe | Inconel 625 welded pipes |

|---|---|---|

| Common buyer intent | Simplify acceptance for critical duty | Fit size/availability and controlled inspection scope |

| Typical acceptance focus | Base material traceability, mechanical results | Weld seam quality + NDT records + traceability |

| Risk point to manage | Lead time on uncommon sizes | “Like-for-like” NDT/document scope vs RFQ |

| Best fit examples | Critical service, fatigue-sensitive layouts | Size-driven projects where weld inspection scope is defined |

Inconel 625 Pipe Sizes and 625 OD Pipe (How sizes are specified)

Inconel 625 pipe sizes are commonly expressed as NPS + schedule, while “625 OD pipe” requests typically indicate OD-driven engineering or retrofit constraints.

A complete line item usually identifies: size format (NPS + schedule or OD + WT), length (random or fixed), end preparation (PE/BE/threaded where applicable), and any special requirements tied to straightness and tolerances.

Inconel 625 Pipe Schedule Chart (Practical Reference)

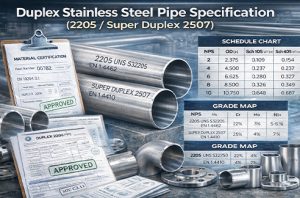

An inconel 625 pipe schedule chart is used to translate NPS into OD and wall thickness, so quotes remain consistent across suppliers. The schedule values below follow common ASME B36.10 references for OD and typical wall thickness by schedule (confirm exact requirements in the governing project standard).

Common NPS schedule reference (OD in inches, WT in inches)

| NPS | OD | Sch 10 WT | Sch 40 WT | Sch 80 WT |

|---|---|---|---|---|

| 1/2 | 0.840 | 0.083 | 0.109 | 0.147 |

| 1 | 1.315 | 0.109 | 0.133 | 0.179 |

| 2 | 2.375 | 0.109 | 0.154 | 0.218 |

| 4 | 4.500 | 0.120 | 0.237 | 0.337 |

| 6 | 6.625 | 0.134 | 0.280 | 0.432 |

Material & Properties Buyers Actually Check (What matters at receiving)

For Alloy 625 purchasing, “material properties” only matter if they can be verified against the PO line item and the project ITP. At receiving, the most common non-conformities are not “wrong alloy grade on paper,” but mismatches between the ordered condition and what is physically delivered—especially when multiple heats, lots, or mixed product forms arrive in split shipments.

What buyers and inspectors typically check first:

• Heat number to piece traceability: Every pipe should be traceable to the heat shown on the MTC. If you receive mixed heats, require a heat-to-piece list (and keep it aligned to bundle tags / piece marking) to avoid mixed-lot stocking issues.

• MTC chemistry and mechanical results tied to the correct product form: The MTC should clearly indicate the product type (pipe/tube), heat number, and test results that correspond to that heat. For critical service, buyers often ask for a clear statement of the manufacturing route (seamless/welded) and any required heat treatment condition stated on the PO.

• Dimensional conformity that affects fit-up: OD, wall thickness, length, straightness, and end preparation (PE/BE) are the items that most often cause site handling delays. A simple dimensional report (OD/WT/length checks) helps receiving inspection move faster—especially for OD-driven “625 OD pipe” requests.

• Verification for wrong-material risk (PMI when required): If your project requires PMI, align the PMI scope (100% pieces vs sampling, method, reporting format) with the ITP up front so it doesn’t become a dispute after delivery.

• Surface condition and end condition: For nickel alloy pipe, surface and bore condition are practical indicators of handling and finishing quality. If the service is cleanliness-sensitive or fabrication-sensitive, confirm expectations on surface finish and end protection in the RFQ so “acceptable” is not left to interpretation.

The point is simple: good receiving outcomes come from matching the ordered condition + inspection scope + traceability discipline—not from generic textbook property tables.

Inconel 625 Pipe Fittings and Nickel Alloy 625 Pipe Flanges

Pipe packages often expand into fittings and flanges, and that’s where projects lose time—because the interface rules change. Many “field fit-up problems” are actually specification alignment problems: end preparation, dimensional standards, facing types, and documentation are not synchronized across vendors.

To avoid interface and approval issues, buyers typically lock these items early:

• Connection and dimensional standard: Confirm what governs the interface—ASME B16.9 for butt-weld fittings, ASME B16.5 / B16.47 for flanges, MSS where applicable, and the agreed tolerances. Even when alloy grade is correct, a mismatch in standard or tolerance can stop fabrication.

• Facing type and flange details: If flanges are included, specify facing (RF/RTJ), pressure class, and any project-specific requirements that must appear on the MTC/marking.

• “Matching documents” across pipe + fittings + flanges: Receiving goes smoother when the document pack is consistent: MTC format, heat identification, traceability list, and any required PMI/NDT reports. If multiple suppliers are involved, require a unified traceability list format so the EPC/owner can review without rework.

• Weldability and fabrication readiness: For butt-weld items, buyers care about end prep quality, bevel geometry, and consistency of wall thickness at the joint. It’s common to include a note in the RFQ that bevels and ends must be suitable for the intended WPS/PQR and that markings remain readable after normal handling.

• Like-for-like scope when comparing offers: Two bids may both say “Alloy 625 fittings,” but differ in inspection scope, marking discipline, and document completeness. If you compare pricing, compare the same inputs: standards, size range, facing, heat treatment condition (if specified), and inspection/document pack.

In short, fittings and flanges are not “add-ons.” They are interface components, and interface components need standard alignment + document alignment to prevent site delays.

Special Configurations: 625 Pipe Screens and Aerospace Use

Some applications use Alloy 625 because the environment is harsh, but the acceptance focus changes depending on what the product is doing.

625 Pipe Screens are usually bought for filtration or sand-control type duty, where corrosion resistance is only one part of the requirement. In practice, buyers pay attention to:

• Dimensional control that affects performance: OD/ID, straightness, and critical features (slot/opening geometry or screen pattern, if applicable) often drive acceptance more than nominal alloy grade.

• Consistency and inspection reporting: For screen-type products, a basic report that confirms critical dimensions and visual condition can prevent disputes at receiving—especially when the screen geometry is tied to flow or erosion performance.

• Handling and protection: Screens can be more damage-sensitive than plain pipe. Packaging and end protection should be defined because dents or edge damage can affect function, not just appearance.

For aerospace-oriented Alloy 625 use cases, the purchasing pattern is different: the emphasis is often on repeatability and documentation discipline rather than “one-off mill capability.” Buyers tend to require:

• Tighter documentation control: Clear traceability, consistent certificate format, and repeatable records across lots (helpful for qualification workflows).

• Lot control and change control mindset: Even when specifications allow flexibility, aerospace-style procurement often expects stable process records and predictable documentation packages.

• Clarity on what is being qualified: If the end-use is qualification-driven, define up front whether you are qualifying material, manufacturing route, inspection scope, or a specific supplier’s delivery pack—so acceptance criteria are measurable.

These “special configurations” are where most delays happen if requirements remain implicit. The fastest way to prevent that is to make the acceptance items explicit in the RFQ: critical dimensions, inspection scope, packaging, and document set.

Alloy 625 Pipe Suppliers: How to Qualify a Supplier

When evaluating alloy 625 pipe suppliers or inconel 625 pipe suppliers, capacity alone is rarely the blocker—documentation and traceability are. Ask whether the supplier can provide an acceptance-ready pack (MTC, PMI if required, NDT reports where applicable, dimensional inspection, and a heat-to-piece traceability list) aligned to your ITP.

Supplier document pack checklist (what commonly reduces approval cycles)

| Document / record | What it proves | Why it matters at receiving |

|---|---|---|

| MTC (EN 10204 3.1 commonly requested) | Chemistry/mechanical results tied to heat | Confirms compliance to the purchased spec |

| Marking + traceability list | Heat-to-piece mapping | Prevents mixed-lot and audit gaps |

| Dimensional inspection | OD/WT/length/tolerances | Confirms what was actually delivered |

| PMI (when required) | Alloy identity verification | Reduces wrong-material risk |

| NDT reports (when specified) | Defect screening per ITP | Supports owner/EPC acceptance |

| Third-party inspection release (when required) | Independent witness/verification | Speeds EPC/owner approval on controlled projects |

Inconel 625 Pipe Price (and why “price list” rarely matches reality)

Inconel 625 pipe price is rarely a single number because the quote is heavily shaped by specification inputs and acceptance scope. Buyers searching “inconel 625 pipe price list” typically want a faster way to compare offers, which comes from locking the same inputs across bids.

Main price drivers for Alloy 625 pipe

| Price driver | What changes cost most |

|---|---|

| Raw material cost | Nickel alloy input volatility and melt route |

| Size (OD/WT or schedule) | Material weight + manufacturing feasibility |

| Manufacturing route | Seamless vs welded route and inspection scope |

| Inspection & documentation | PMI/NDT/traceability requirements |

| Quantity & delivery schedule | Mill planning, batch efficiency, expediting |

| End prep and additional processing | Beveling, special lengths, bundling/packing |

Why Choose Octal Steel for Inconel 625 Pipe Supply

In nickel alloy projects, the fastest way to lose schedule is not the material itself—it’s approval friction: unclear inspection scope, mixed-heat traceability gaps, and document packs that don’t match what the PO actually asks for. Octal Steel is set up to reduce that friction by treating Alloy 625 supply as an acceptance-ready delivery, not a “ship-first, explain-later” transaction.

What buyers typically gain when sourcing Inconel 625 pipe / Alloy 625 pipe through Octal Steel:

• RFQ-to-PO specification alignment (so quotes are truly like-for-like).

We confirm the size expression (NPS + schedule vs OD + WT), manufacturing route (seamless vs welded), required condition, end preparation, and the project inspection requirements before the order is released. This prevents the most common dispute at receiving: “the product is fine, but it’s not what the line item intended.”

• Documentation-first submission pack built for EPC/Owner review.

Nickel alloy approvals often stall because certificates are incomplete or inconsistent. Our standard delivery pack is organized around what review teams check: MTCs in a consistent format, marking/heat identification, a heat-to-piece traceability list, and dimensional inspection records. When additional verification is specified (PMI, NDT, third-party witness), those reports are compiled into the same submission structure so the ITP can be closed without multiple revision rounds.

• Traceability discipline for split shipments and mixed heats.

Alloy 625 orders are frequently delivered in batches. We keep traceability usable at site by maintaining piece-level marking visibility and providing a traceability list that maps heats to bundles/pieces, reducing mixed-lot stocking risk and audit gaps during receiving inspection.

• Inspection scope clarity for seamless vs welded supply.

When welded pipe is part of the scope, acceptance is usually driven by weld seam control and NDT records. We help buyers avoid “document mismatch” by confirming the required inspection plan for welded products (and ensuring the reporting format matches what the project expects), so the welded portion does not become the bottleneck.

• Packaging and end protection designed to protect acceptance condition.

Many nickel alloy “issues” are actually handling damage: end deformation, surface damage, or lost marking. We use practical export packaging and end protection so pieces arrive in the condition required for fabrication and inspection, not just “arrived.”

FAQ

Q1: What is Inconel 625 pipe used for?

A1: Inconel 625 pipe (Alloy 625 pipe / 625pipe) is commonly selected for corrosive media and high-temperature service where projects require corrosion resistance plus strength, supported by traceable documentation and acceptance testing aligned to the job.

Q2: Inconel 625 seamless pipe vs Inconel 625 welded pipes — which should I choose?

A2: Inconel 625 seamless pipe is commonly chosen for critical duty and simplified acceptance, while Inconel 625 welded pipes can fit certain size and availability requirements when weld seam inspection scope and documentation match the project ITP.

Q3: How do I read an Inconel 625 pipe schedule chart?

A3: A schedule chart converts NPS into OD and typical wall thickness by schedule. Using the same NPS and schedule across bids prevents suppliers from quoting different wall thickness assumptions under the same nominal size.

Q4: What should buyers check when comparing Inconel 625 pipe suppliers?

A4: Beyond capacity, the deciding factor is usually documentation discipline: consistent MTC format, heat-to-piece traceability, dimensional inspection records, and any required PMI/NDT reports aligned to the project ITP.