Carbon Steel Flange

Grades: ASTM A105N (SA105N) / A350 LF2 / A694 (F42–F70)

Types: WN / SO / BL / LAPJ / SW / THD

Standards: ASME B16.5 / MSS SP-44 / DIN 2533

Pressure range: ASME Class 150–2500

Docs: MTC + heat/lot traceability + packing list mapping

Protection: zinc / paint / oil varnish + face protectors

A carbon steel flange is a flange made from carbon steel—steel where carbon is the primary alloying element (higher carbon content than stainless steels that rely on chromium for corrosion resistance)—and it is used as a bolted, gasketed joint to connect pipes, valves, and equipment. In real projects, the early failure and rework risks are usually not about “what a flange is,” but whether the delivered carbon steel grade (for example, ASTM A105N), pressure class, facing, bolt pattern, and traceability match the piping specification and can be released at receiving without site modification.

Common carbon steel flange standards typically include ASTM A105/A105N, ASTM A350 LF2, and ASTM A694 for material, and ASME B16.5, MSS SP-44, and DIN 2533 for flange dimensions/patterns; the usual pressure rating range is ASME Class 150–2500, selected by the project design pressure/temperature and required facing (RF/RTJ/FF).

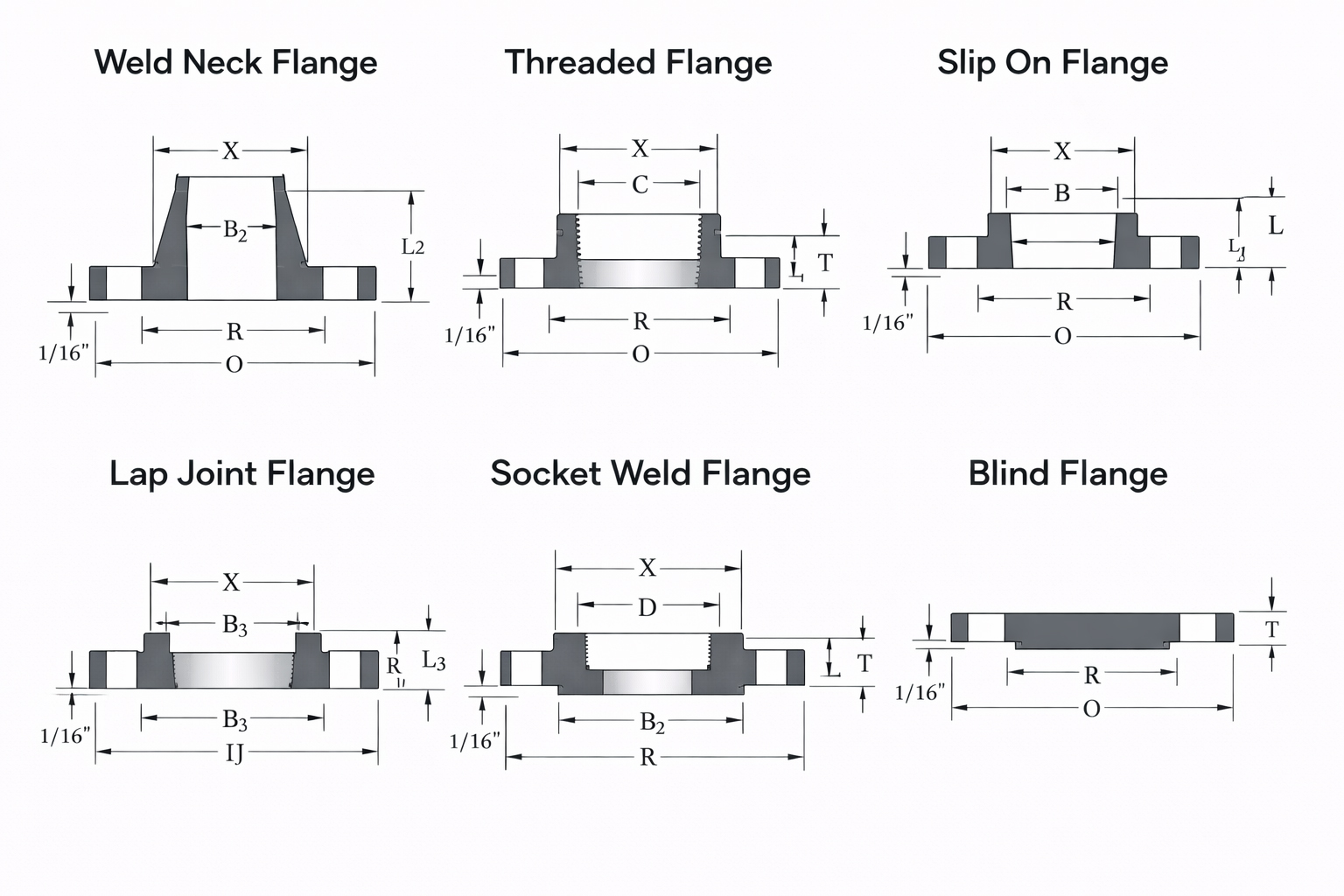

Forged Flange Types Commonly Specified

Procurement usually starts with flange type, then locks material grade and standard.

• SO (Slip On): slips over pipe OD and is fillet welded; selected when fit-up speed and availability matter.

• SW (Socket Weld): socket connection with fillet weld; common for smaller sizes where compact joints are preferred.

• THD (Threaded): threaded connection; used when welding is restricted or avoided by procedure.

• LAPJ (Lap Joint): used with a stub end; favored where frequent dismantling or alignment flexibility is needed.

• WN (Weld Neck): butt-welded neck for better stress distribution; often chosen for higher class or more critical sealing service.

• BL (Blind): closes line ends; used for isolation, hydro-test boundaries, and future tie-in points.

Carbon Steel Flange Grades for Pressure Piping

Common standards used for carbon steel flanges include ASTM A105N (SA105N), ASTM A350 LF2, ASTM A694, plus dimensional systems such as DIN 2533 and MSS SP-44 depending on project requirements. Pressure ratings commonly run from Class 150 to 2500.

Below is the practical split by service condition:

⒈ ASTM A105N (SA105N): default forged flange grade for ambient and higher-temperature pressure systems — commonly used in refinery/process piping tie-ins, pump/valve nozzle connections, and general plant utility lines.

⒉ ASTM A350 LF2: used where low-temperature toughness is specified — commonly used in cold-climate oil & gas pipelines, LNG-related piping/skids, and outdoor winterized units.

⒊ ASTM A694 (F42–F70): used for high-pressure fluid transmission where higher strength levels are required — commonly used in oil & gas transmission pipelines, compressor/booster stations, and high-pressure trunk lines.

ASTM A105N (SA105N)

ASTM A105N (SA105N) is the default forged carbon steel flange grade for general pressure-piping service because it balances strength, toughness, availability, and cost for ambient to higher-temperature systems. It is widely used across oil & gas, process plants, and general industrial piping, and it is also commonly specified as a carbon steel lap joint flange when paired with a lap joint stub end/end ring—a practical way to keep the flange in carbon steel while the wetted piping is stainless steel.

In project supply, SA105N is typically offered in Blind (BL), Weld Neck (WN), Lap Joint (LAPJ), and Slip-On (SO) types, with common stock ranges such as 18″ to 42″ in ASME Class 150 and 300. Other sizes and pressure classes are also available—often with longer lead times—such as 12″ to 60″, depending on type, facing, and machining requirements.

Ordering Data That Prevents Fit-Up Rework

A105N flange orders release faster when these fields are explicit:

• Flange type: SO / SW / THD / LAPJ / WN / BL

• Dimensional standard: ASME B16.5 / MSS SP-44 / DIN pattern (as specified)

• Pressure class: Class 150–2500 (as specified)

• Facing: RF / RTJ / FF

• Size & bore: NPS/DN and bore/schedule match intent (especially for WN and SO)

• Traceability: piece marking tied to heat/lot and MTC

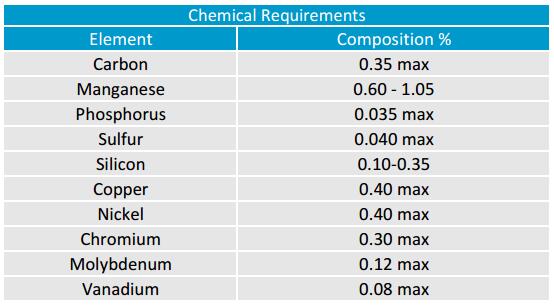

Chemical composition of ASTM A105N Flange

For ASTM A105N carbon steel flanges, the quickest way to pass incoming inspection is to confirm the heat chemistry on the MTC matches the specification limits. This is especially important when the flange will be welded into a pressure boundary, or when multiple heats are delivered under one PO and you need clean lot identification. The table below is a line-by-line reference to verify the reported heat analysis against the ASTM requirements.

| Element | Requirement (Heat Analysis, wt%) | MTC Check (Buyer Acceptance) |

|---|---|---|

| C | 0.35 max | Heat C ≤ 0.35% |

| Mn | 0.60–1.05 | Heat Mn within range (see NOTES) |

| P | 0.035 max | Heat P ≤ 0.035% |

| S | 0.040 max | Heat S ≤ 0.040% |

| Si | 0.10–0.35 | Heat Si within range |

| Cu | 0.40 max | Heat Cu ≤ 0.40% |

| Ni | 0.40 max | Heat Ni ≤ 0.40% |

| Cr | 0.30 max | Heat Cr ≤ 0.30% |

| Mo | 0.12 max | Heat Mo ≤ 0.12% |

| V | 0.08 max | Heat V ≤ 0.08% |

| NOTES: Each reduction of 0.01% for above specified carbon maximum (0.035%), an increase of 0.06% of Mn maximum (1.05%) will permitted up to a maximum of 1.35%. The sum of Cu, Ni, Cr, Mo, and V shall not exceed 1.00%. Cr + Mo shall not exceed 0.32%. |

||

Mechanical properties of A105N

Mechanical properties on the MTC confirm the material meets minimum strength for pressure service and supports stable bolt-up and gasket seating under load. For receiving release, check tensile strength and yield strength first, then ensure the report shows a clear test basis where applicable (specimen type/thickness) so results can be accepted without back-and-forth. The table below summarizes the key mechanical requirements and what to verify on the test report.

| Item | Requirement | MTC Check (Buyer Acceptance) |

|---|---|---|

| Tensile strength | ≥ 485 MPa (70,000 psi) | UTS recorded and meets minimum |

| Yield strength | ≥ 250 MPa (36,000 psi) | YS recorded and meets minimum |

| Elongation | Per ASTM A105/A105N requirements (specimen basis) | Specimen type/thickness basis stated on report |

| Hardness | Per ASTM A105/A105N limit (when required) | Hardness value recorded and within limit |

Receiving Acceptance Focus for A105N

A105N flange release typically depends on whether the shipment can be verified without interpretation:

· Marking-to-MTC match: piece marking shows grade and traceable heat/lot that matches the MTC.

· Dimensional compliance: OD/ID (bore), thickness, bolt circle, hole count/diameter, and facing type match the ordered standard and class.

· Facing protection: RF/RTJ faces arrive protected from dents, scratches, and corrosion to prevent gasket performance issues.

· Documentation completeness: MTC plus any project-required inspection records (dimensional, visual, NDT scope if specified).

· Lot mapping: packing list maps bundles/crates to heat/lot so receiving inspection and site issuance don’t mix heats.

ASTM A350 (SA350) LF2 Flanges (Low-Temperature Service)

A350 LF2 is selected when low-temperature service requires notch toughness control and impact performance. It is often specified in oil & gas and industrial applications where design temperature drives material qualification beyond A105N.

LF2 is commonly supplied as WN, SO, and BL depending on class and maintenance needs, with acceptance emphasis on traceability plus low-temperature test evidence required by the project specification.

ASTM A694 Flanges (High-Strength / Pipeline Service)

ASTM A694 is specified when pipeline and transmission service demands stricter strength and qualification controls than typical general-purpose grades such as SA105N or SA350 LF2. It is widely used for high-pressure fluid transmission in oil and gas piping systems, where the purchasing focus is not only dimensional compliance, but also the higher-strength material provisions that support demanding pressure and operating conditions across a wider temperature envelope.

Each ASTM A694 grade is identified by a number that correlates to its minimum yield strength (for example, F42 through F70). In practice, this grade designation becomes the key acceptance checkpoint: it must be clearly shown on the marking and confirmed on the MTC, so the flange can be released for installation without rework or material clarification.

Forged steel Flange – A common manufacturing type for carbon steel flange

There are several ways to manufacture the flanges, mostly are forging and casting.

As we know, flange is a plate-like round device that is affixed at the end of a pipe, valve, fitting, etc. It helps in putting together a piping system. Manufacturers develop flanges of any material so that it matches the material being used for fittings and pipes. But mostly are two ways: Cast iron and forged in carbon steel.

Forged Steel Flange

A superlative mechanical property of any flange product is forged steel flange, which is made up of stainless steel, alloy steel or carbon steel. Raw materials (mostly is pipe body) are cut and beaten to get rid of the block and defects. Compared to ordinary casting flange, the cost and mechanical properties tend to be higher. A flange connects pipes to other pipes with a valve attached to the pipe end, which is also used for flange on outlets and inlets. The link between the devices is what connects one pipe to the other. At the end of the tube is an alternative pipeline accessory.

The primary standards have forged flange are American Standard, Japanese Standard, German Standard, Superscript, etc. Oil is the key anti-corrosion treatment, which improves temperature performance and forging flange pressure in both high temperature and pressure working settings.

Differences between forged steel flange and cast iron flange

From a buying and service-risk perspective, the biggest difference is consistency under pressure. Forged steel flanges are typically preferred for pressure piping because the material structure is more consolidated and tends to deliver higher mechanical strength and more predictable performance in bolted gasket joints. Casting can be attractive for complex profiles and lower manufacturing cost, but procurement risk often shifts to defect control and verification scope—especially when the service involves pressure containment.

The practical points below reflect how these two routes compare in everyday procurement and site outcomes:

b. Forging process will not make big or uneven brain, cost is higher than cast iron.

c. Forged steel is easy to be cut and can take higher tensile strength.

d. Casting iron could be made to different and complicated profiles, cost lower.

e. Cast iron steel exists air bubble, harmful defects, where forged steel flange don’t.

f. Use Centrifugal machine will produce higher precision cast iron flange than normal cast flanges.

g. Forged steel flange could be used in higher pressure pipelines, where cast iron flange only could be used in non-pressure pipelines, otherwise will cause leaking problems.

For purchasing decisions, the takeaway is simple: when the line is pressure-rated and sealing performance must be stable after bolt-up, buyers typically prioritize forged steel flanges because the verification workload is lower and the risk of internal discontinuities is reduced. When the application is non-pressure or cost-driven and complex shapes are needed, cast options may be considered—provided the project specification clearly defines acceptance criteria and inspection scope so receiving release does not stall.

Rust Prevention and Storage

Carbon steel flanges can rust during transit and yard storage. Anti-rust delivery condition is typically aligned to shipping route, storage duration, and whether the material will stage outdoors.

Electric Zinc Coated (White or Yellow Zinc)

Zinc coating is used when flanges may see extended handling, humid warehouses, or staging where flash rust is a frequent rejection trigger. Coverage consistency matters for bolt holes and external surfaces, while sealing faces still require dedicated protection to avoid coating interference or face damage. Typical receiving checks include uniform coating, clean bolt holes, intact face protectors, and no coating buildup that affects fit-up.

Anti-Rust Painting

Anti-rust paint is often used for outdoor staging or mixed-mode logistics (yard storage + site installation). The purchasing focus is that paint stays off RF/RTJ sealing surfaces and does not build up around bolt holes. Receiving checks commonly include paint condition after transit (chips/abrasion), masking quality on sealing faces, and touch-up compatibility if staging is expected.

Oil Varnished

Oil varnish is frequently selected for sea shipment and longer storage where moisture ingress drives corrosion. Performance depends on a continuous film plus packaging discipline (face protectors, sealed wrapping, moisture control). Receiving checks often include intact packaging, continuous oil film without dry patches, no water staining, and protected faces suitable for gasket sealing.

Delivery & Documentation Controls (Octal)

When you qualify a carbon steel flange manufacturer for a pressure-piping project, the real bottleneck is usually site release: interface accuracy, traceability, inspection evidence, and transit protection. Octal’s controls are built to keep the document package and receiving checks aligned so material can move from RFQ to installation without unnecessary holds.

Spec alignment before production

As a carbon steel flange manufacturer, Octal reduces fit-up delays by controlling the four most common mismatch points at RFQ/PO stage: facing (RF vs RTJ), drilling pattern, bore intent, and flange type. A typical failure is ordering Class 300 correctly but receiving RF when the piping class requires RTJ, or receiving a WN flange with a bore that does not match the intended pipe schedule. By locking type + class + facing + standard + bore as one interface set, Octal helps avoid re-facing, re-drilling, and gasket mis-selection that usually appears only after crates are opened on site.

Traceability that closes audits

Octal treats traceability as a receiving-release requirement expected from a carbon steel flange manufacturer: flanges are often held not because chemistry is “wrong,” but because heat identity cannot be proven after packing and site staging. A common issue is mixed heats on one pallet while only one MTC is attached, or markings that can’t be linked back to the MTC after handling. Octal organizes piece marking, issues MTC per heat/lot, and supports crate/package → heat/lot mapping so receiving teams can sample and release by lot without re-identifying every flange.

Inspection organized to project ITP

For a carbon steel flange manufacturer, the inspection evidence that matters most is what blocks release in real receiving bays: bolt circle, hole quantity/diameter, thickness, bore, and facing type/condition. A recurring site problem is “holes don’t line up” because the delivered flange matches a different pattern standard, or gasket leakage traced to a damaged face. By documenting the ordered standard/class and the measured drilling/facing items in a way that aligns with project ITP expectations, Octal reduces back-and-forth and prevents full-batch re-measurement at receiving.

Protection matched to logistics

Octal manages anti-rust treatment and packing as a carbon steel flange manufacturer would for sea freight and outdoor staging, because many rejections come from handling damage rather than metallurgy—typically scratched RF faces or dented/flash-rusted RTJ grooves. With zinc/paint/oil varnish options for external surfaces and dedicated face protection plus sealed packing, Octal helps keep sealing faces install-ready and reduces avoidable rework such as cleaning, re-finishing, or holding material for replacement.

FAQ

Q1: What is the difference between ASTM A105 and ASTM A105N for carbon steel flanges?

A1: ASTM A105 is the specification for forged carbon steel piping components; “A105N” indicates normalized condition when normalization is required by the order or project specification.

Q2: Which forged flange types are commonly supplied in ASTM A105N?

A2: ASTM A105N is commonly supplied as WN, SO, LAPJ, and BL, selected by pressure class, sealing criticality, and maintenance access requirements.

Q3: What are the most important receiving checks for A105N flanges?

A3: The key release items are marking-to-MTC traceability, dimensional compliance to the ordered standard/class, intact facing protection, and complete documentation for the required inspection scope.

Q4: Which anti-rust delivery condition is suitable for sea shipment and longer storage?

A4: Oil varnish is commonly used for sea shipment and longer storage where moisture ingress is the main corrosion driver, typically paired with sealed packing and face protection to preserve sealing performance.