3LPE coating standard and tests

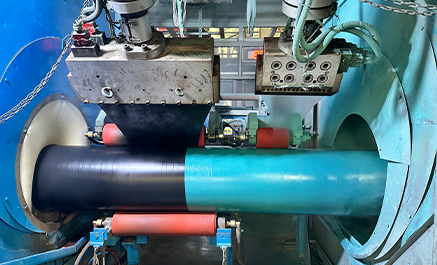

A 3LPE system is only as reliable as its process control and verification. Most projects define the coating requirement through a coating standard/specification and then confirm compliance through routine tests and inspection records.Common checks for

3LPE coating standard compliance typically include:

• Coating thickness measurement (FBE/adhesive/PE and total thickness per the spec)

• Holiday detection (to confirm coating continuity and locate pinholes/defects)

• Adhesion / peel strength testing (to verify bonding performance between layers)

• Impact resistance testing (to validate mechanical robustness during handling/back-fill)

• Bend / flexibility testing (as required by the project standard)

• Cathodic disbondment testing (often required for buried pipeline coatings)

• Visual inspection + repair records (defect repair method and acceptance results)

For procurement and site acceptance, the most valuable outcome is a clear, consistent inspection pack that ties coating results back to pipe identity and heat/lot traceability.