Steel Casing Pipe API 5CT

Octal supplies API 5CT Casing Pipe in J55/K55, N80Q, P110 BTC and Premium Connection

Range of Sizes: 5 1/2” to 20”

Ends Type: BTC, LTC, Premium Connection Casing Pipe

Length: R2, R3

In modern oil and gas drilling and production engineering, wellbore integrity is the fundamental principle ensuring structural safety, preventing formation fluid influx, and protecting the environment. The selection of API 5CT casing grades is pivotal, as it directly determines the well’s ability to withstand specific challenges related to depth, pressure, and corrosive media.

Octal Steel offers a comprehensive range of API 5CT-compliant casing pipes. Our scientifically graded product portfolio is engineered to precisely meet requirements ranging from standard wells to extreme service conditions. Beyond standard-strength grades like J55/K55, N80 Type 1, and P110, we provide high-performance options designed for demanding environments:

The Balance of Corrosion Resistance and Medium Strength: The L80 grade, one of the most widely used sour-service grades, has its hardness strictly controlled below HRC 23, delivering reliable resistance to Sulfide Stress Cracking (SSC) in environments containing Hydrogen Sulfide (H₂S).

Combining High Strength and Corrosion Resistance: C90 and T95 grades offer higher strength than L80 while maintaining excellent SSC resistance, making them suitable for deeper, higher-pressure sour wells.

Ultra-High-Strength Support: P110 and Q125 grades are designed to provide superior collapse and internal pressure resistance for ultra-deep wells, high-pressure formations, or sections requiring extreme structural support.

Dedicated CO₂ Corrosion Solutions: In addition to standard carbon and alloy steel grades, we supply 13Cr and higher-alloy martensitic stainless steel pipes, which effectively combat CO₂-induced uniform corrosion through the formation of a dense passive film.

We recognize that each grade embodies an application of materials science. Consequently, through precise metallurgical design (e.g., employing Quenching & Tempering for N80Q to achieve a fine, uniform tempered sorbitic structure) and rigorous end-to-end quality verification, Octal Steel ensures every joint of casing delivers its promised mechanical properties and durability under complex down-hole stress and chemical conditions. Choosing Octal Steel means selecting an engineering assurance rooted in a profound understanding of materials, providing a solid foundation for your asset integrity and operational efficiency.

Octal Steel provides a comprehensive selection of API 5CT steel casing and tubing pipes to meet various needs in oil exploration and production. The materials offered include carbon steel (the most commonly used), alloy steel, chrome steel, and high alloy steels. The API 5CT grades available encompass J55/K55, N80 Type 1, N80Q, L80, C90, T95, P110, and Q125, along with additional specifications for 13 Cr.

Steel Casing pipe Feature

Casing pipe section shape is a round, big diameter pipe put into the oil well, fixed by the cement, to protect other equipment which is mostly made of iron and steel. Oil wells shall be designed to bear the different strengths of external power, such as crush, explosion, stress, and chemical corruption. During the well drilling process, put casing into the well bore, it will stabilize the well bore perfectly.

Key Features of Steel Casing Pipe:

- Material: Typically made from high-strength steel, casing pipes are engineered to withstand high pressures and harsh conditions encountered during drilling operations.

- Standards: Steel casing pipes often conform to industry standards such as API 5CT, which specifies the requirements for casing and tubing used in the oil and gas industry.

Application

API 5CT casing pipe is used to support the oil and gas pipe wall and to ensure the drilling process and the post-completion wells’ normal operation. Each well depending on the depth of drilling and geological conditions, uses several layers of casing. After cementing casing to be used to go down, it is different from tubing, and drill pipe and can not be reused, a one-time consumable material. Therefore, the casing consumption accounts for over 70% of all the oil well pipe. According by usage can be divided into the sleeve pipe, surface casing, casing, and production casing.

API 5CT Casing and Tubing in Oil & Gas OCTG

API 5CT casing and tubing are the two primary strings in OCTG casing and tubing systems used across casing and tubing oil and gas wells. Casing provides well bore integrity and zonal isolation (commonly cemented in place), while tubing is the inner production conduit used for flowing or injecting fluids and can be retrieved during work-over.

In practice, casing and tubing are designed as a system: the casing string defines the well bore barrier and supports external loads, while the tubing string manages production flow conditions and pressure cycling. This page focuses on API 5CT casing pipe, with related tubing specifications and charts referenced for quick cross-checking.

Difference Between Casing and Tubing

• Function: Casing stabilizes formations and isolates zones; tubing carries produced/injected fluids to surface.

• Placement: Tubing typically runs inside casing, creating the annulus used for circulation, gas lift, packers, and monitoring.

• Life-cycle: Casing is commonly a permanent barrier; tubing is commonly retrievable and replaceable.

• Design focus: Casing emphasizes collapse/burst/tension under drilling and cementing loads; tubing emphasizes pressure cycling, flow, and work-over handling.

In casing and tubing design, pressure checks are commonly expressed as three fundamentals: burst (internal pressure), collapse (external pressure), and tension (axial load). Grade, wall thickness, and connection type are selected to match the design envelope and service environment (sweet/sour), and to maintain sealing performance under casing and tubing pressure variations.

Octal supply API 5CT steel casing pipe in the below specifications and sizes

Standard: API 5CT

Grades: J55/K55, N80-1, N80Q, L80, C90, T95, P110, Q125 and 13Cr Casing

Range of Sizes: 5 1/2” to 20”

Length: R2, R3

Ends Type: BTC (Buttress Thread Coupling), LTC (Long Buttress Thread Coupling), Premium connection.

Premium connections; Tenaris connections TenarisHydril CS, TSH W511 and Blue Series, Wedge Series 500, Legacy Series; Hunting Connections like Seal-Lock-Flush (SLX), Seal-Lock Semi Flush (SLSF) etc premium connections.

Casing and tubing supplier evaluations in OCTG procurement often focus on traceability, test scope, and connection compatibility. Typical RFQ fields include API 5CT grade and PSL level, OD and wall thickness, thread type (BTC/LTC/STC or premium), coupling requirement, length range (R2/R3), and inspection documentation (MTC, dimensional report, NDT records when applicable). Clear alignment of these fields reduces mismatch risk between casing strings, couplings, and completion hardware.

For projects referencing casing and tubing in oil and gas applications, connection selection is commonly tied to pressure-tight performance, make-up control, and operational handling. Premium connections may be specified when gas-tight sealing, higher torque capacity, or stricter leak resistance is required by the well design envelope.

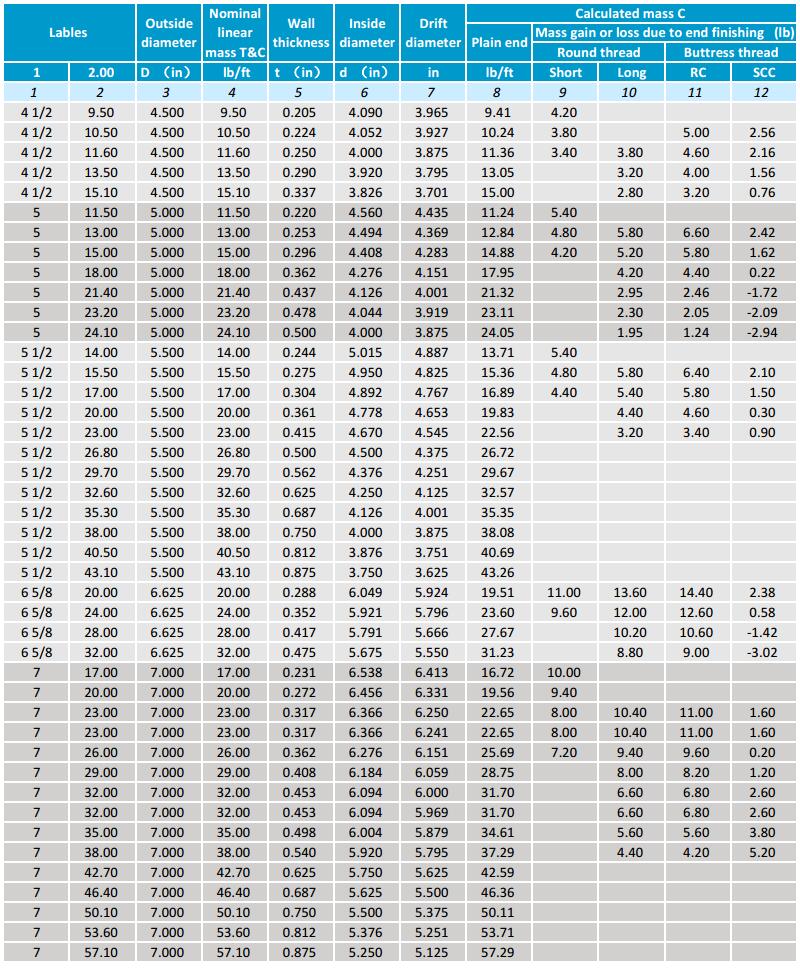

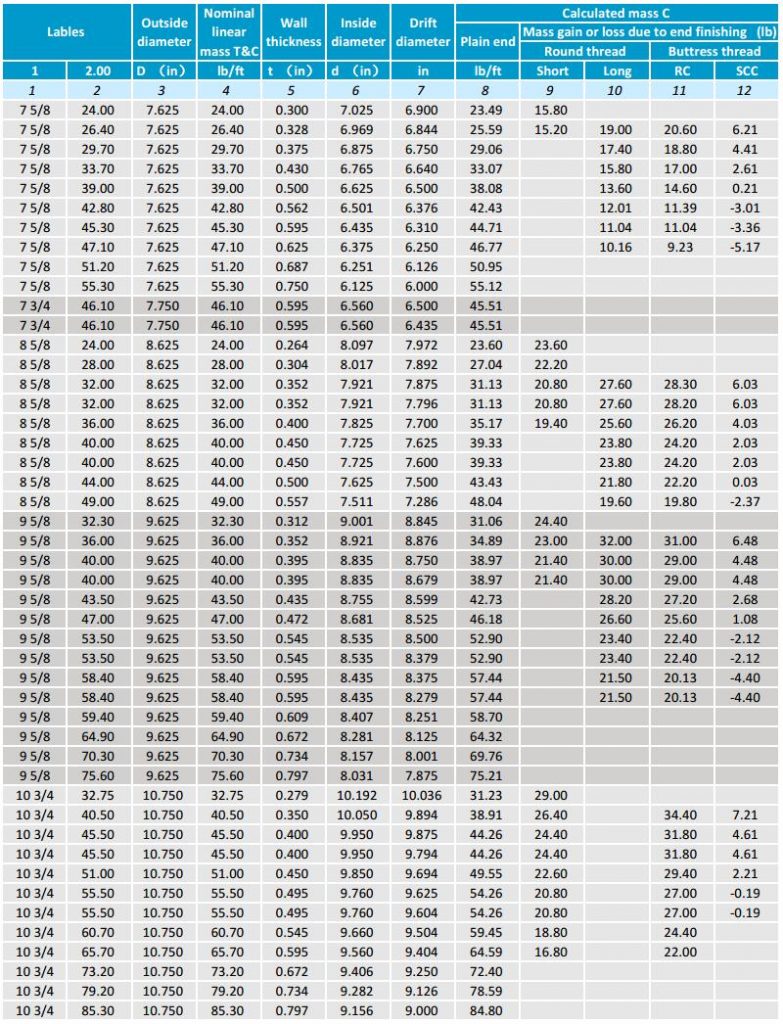

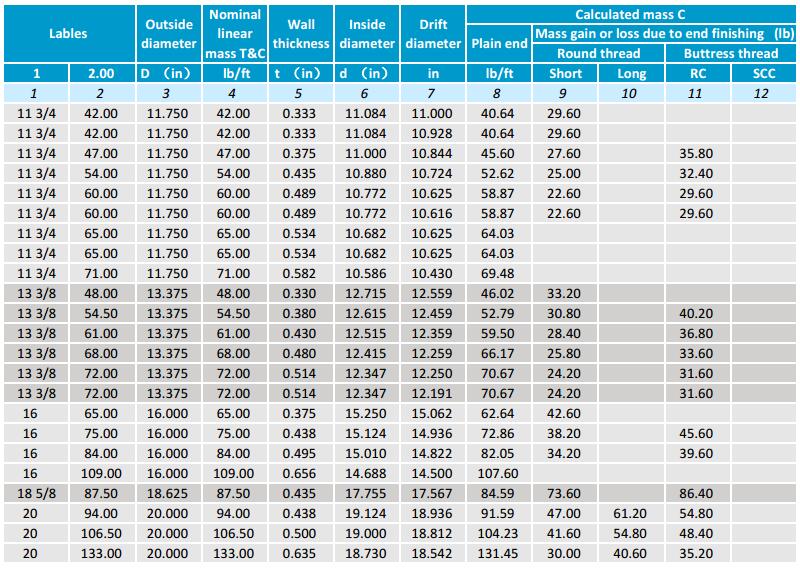

Steel Casing Pipe Dimensions and Weight Chart

Table E.23–Dimensions and masses for standard casing and for casing threaded with API round thread and buttress thread

| API Tubing & Casing Chart Item | Common OD Range | Typical Connections / Ends | Common Length Range | Typical API 5CT Grades |

|---|---|---|---|---|

| API 5CT Tubing | 1.05″–4 1/2″ (common: 2 3/8″, 2 7/8″, 3 1/2″, 4 1/2″) | EUE / NUE / BTC / Premium | R2 / R3 | J55/K55, N80, L80, C90/C95, P110 |

| API 5CT Casing | 4 1/2″–20″ (common: 5 1/2″, 7″, 9 5/8″, 13 3/8″) | BTC / LTC / STC / Premium | R2 / R3 | J55/K55, N80-1/N80Q, L80, C90/C95, P110 |

Annular capacity between casing and tubing is frequently referenced in drilling, cementing, and completion planning because tubing is typically run inside casing and creates an annulus for circulation and system functions. Annular volume between casing and tubing can be expressed using consistent units as:

Annular Volume = (π/4) × (ID² of casing − OD² of tubing) × Length

This annulus geometry affects displacement volumes, fluid returns, and operational checks where casing and tubing dimensions directly control the available annular space.

Our Advantages

Sourcing from all the good API 5CT casing pipe manufacturers in China, Octal is working on providing high quality casing pipe with most competitive price. Especially for the the grades J55/K55, N80-1 and N80Q casing. Moreover, Octal is engaged in providing various premium connection casing pipe, for the server working conditions.

API 5CT Casing Pipe SPEC

In summary, Octal Steel delivers more than just API 5CT casing that meets specifications; we provide high-reliability well-bore barrier solutions built on a deep understanding of materials science, corrosion mechanisms, and drilling engineering. From standard J55/K55 to specialty grades like T95 and 13Cr for extreme conditions, our precise metallurgical control and rigorous quality system ensure product performance in the most complex down-hole environments.

Why Partner with Octal Steel?

Technical Expertise: We are not just a manufacturer but your trusted engineering partner, offering expert support from grade selection and corrosion assessment to custom specifications.

Traceable Quality: Fully traceable quality control from steel-making to finished product, complemented by comprehensive test reports, provides solid assurance for your project’s compliance and safety.

Global Logistics & Support: Leveraging an efficient global supply chain, we ensure timely delivery to your site, backed by responsive technical after-sales service.

Your well-bore integrity starts with the correct selection of foundational materials. Contact our technical sales team today to receive a personalized casing proposal and a competitive quote tailored to your specific geological data and engineering design. Let’s build the success and safety of your next drilling project on a foundation of exceptional materials.

FAQ

Q1: What is the difference between casing and tubing?

A1: Casing is the structural liner installed to stabilize the wellbore and isolate zones (typically cemented). Tubing is the inner string used for production or injection flow and is usually removable for workover.

Q2: What does API 5CT casing and tubing cover?

A2: API 5CT defines the technical and quality requirements for OCTG casing and tubing, including grades, product specification levels, manufacturing and testing requirements, and delivery condition.

Q3: How is casing and tubing pressure evaluated in design?

A3: Casing and tubing pressure performance is commonly checked through burst (internal pressure), collapse (external pressure), and tension (axial load). Grade, wall thickness, and connection type are selected to match the design envelope.

Q4: What is annular volume between casing and tubing used for?

A4: Annular volume is used to estimate displacement and circulation volumes, cementing calculations, and completion planning where annulus space affects fluid returns and operational control.

Q5: Why do some searches mention “AK casing and tubing” or “API tubing and casing pipes in Mississippi”?

A5: These phrases typically reflect destination-based procurement searches. Technical matching still depends on API 5CT grade, size, connection type, PSL level, and required documentation, while delivery terms depend on routing and incoterms.