Steel Pipe Production Line

-

LSAW / SSAW / ERW / seamless + coating in one line

-

Integrated design from forming to testing & coating

-

Intelligent control with real-time production & QA data

-

API / ASTM / EN / GB compliant, turnkey and scalable

Octal Steel provides complete, integrated production lines for LSAW, SSAW, ERW, seamless pipe and anti-corrosion coating. All sections — from plate/coil preparation, forming and welding to NDT, beveling and 3LPE/FBE coating — are designed to work together as one system, not as separate islands of equipment.

When you invest in a steel pipe plant, you are not just buying machines — you are buying production capacity, product quality and delivery reliability for the next 10–20 years.A poorly designed line means bottlenecks, unstable quality and constant troubleshooting. A well-matched line runs smoothly, produces pipes that pass inspection, and helps you win projects.

On top of the mechanical line, we integrate modern intelligent control systems widely used in leading Chinese mills:

Production parameters, welding currents, temperatures, line speeds and NDT results are captured and updated in real time. This kind of digital control and data logging gives you:

- More stable and repeatable product quality

- Full production and QA traceability for every pipe

- Faster troubleshooting when something goes wrong

- Clearer KPI and efficiency monitoring for plant management

For the buyer, this means one responsible supplier for both the production line and its digital backbone, with processes already matched to API / ASTM / EN / GB standards, and a plant that is easier to start up, manage and maintain.

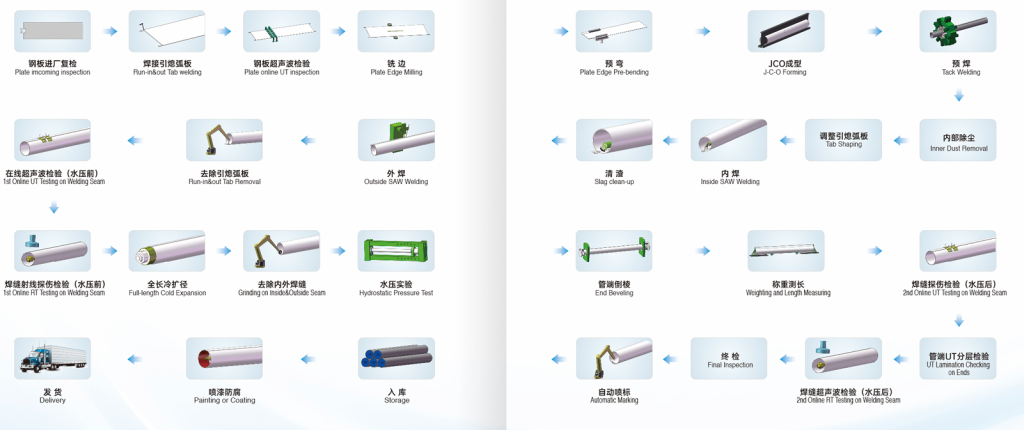

LSAW (JCOE) Pipe Production Line

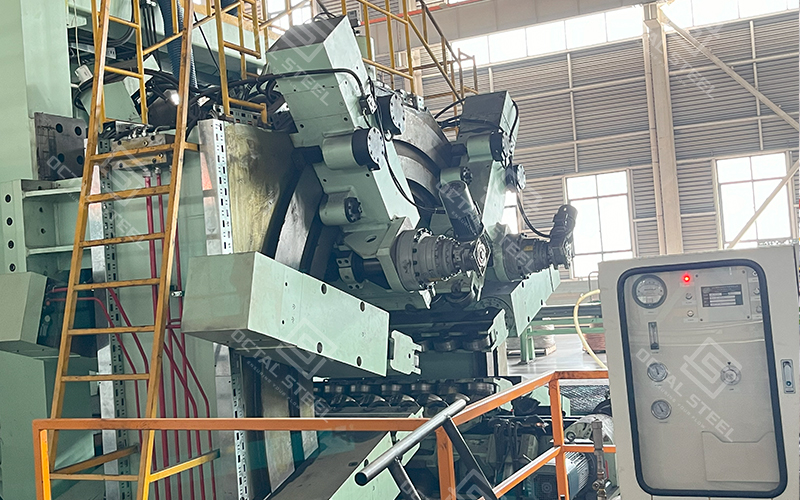

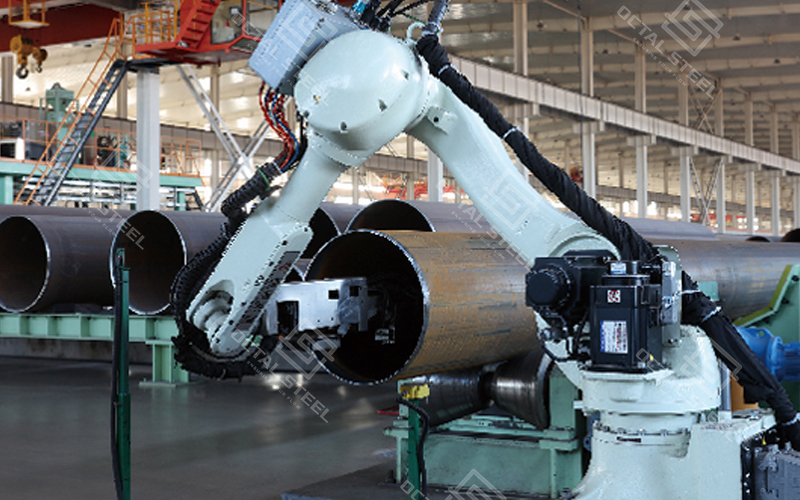

For large-diameter, high-grade line pipe and structural pipe, we offer full JCOE LSAW pipe lines, including:

| Process Stage | Key Equipment | Main Function & Standards Supported |

|---|---|---|

| Raw Material Inspection | Automatic plate UT scanner + laser marking system | 100 % defect detection, full traceability (API 5L, EN 10219) |

| Edge Preparation | High-precision edge milling + crimping machine | Perfect weld bevel geometry, ±0.1 mm tolerance |

| Forming | J-C-O-E progressive press (up to 3000-ton) + pre-bending stands | Uniform roundness, minimal residual stress, OD up to 1626 mm |

| Welding | Internal & external multi-wire (4+4) SAW stations | Full-penetration welds, qualified to API 5L / ISO 3183 |

| Expansion & Sizing | 9-roll mechanical expander / cold expansion unit | Precise OD tolerance ±0.5 %, improved yield strength |

| NDT & Quality Control | Online/offline full-body UT + RT on weld seams | 100 % coverage, meets PSL2 and EN/GB third-party requirements |

| Hydrostatic Testing | High-pressure tester (up to 500 bar) + auto weighing | Verifies pressure integrity and accurate weight calculation |

| Finishing | Flying cut-off, end beveling (30°±5°), cleaning | Ready for field welding and coating, no additional machining |

This line is suitable for producing API 5L / ISO 3183 / GB/T 9711 pipes for long-distance oil, gas and water transmission, as well as heavy structural and piling applications.

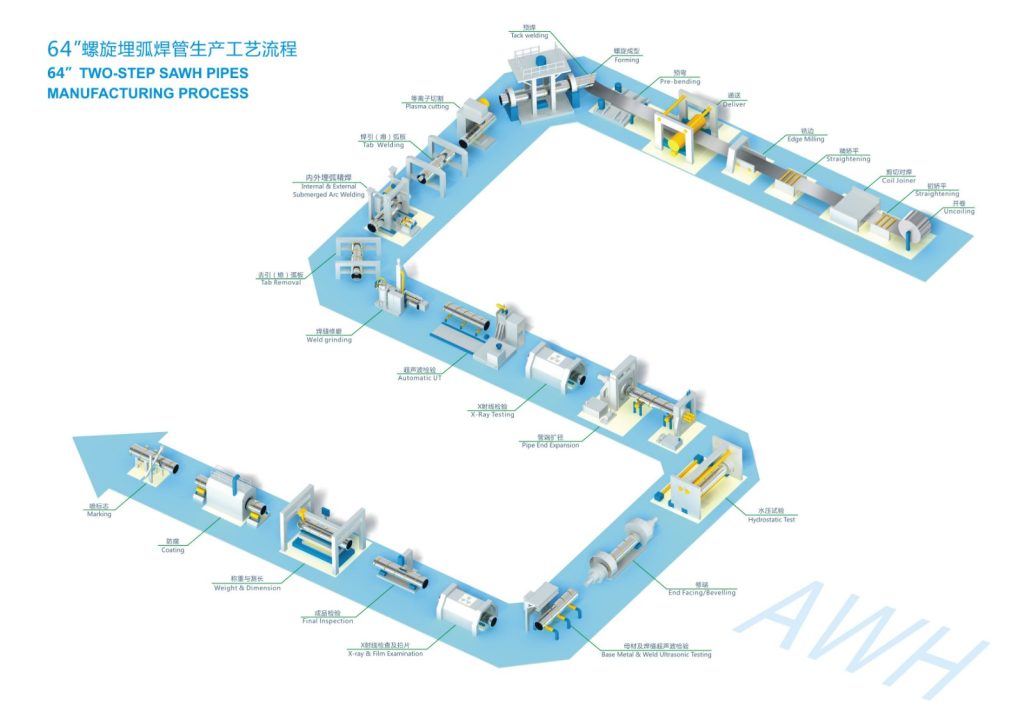

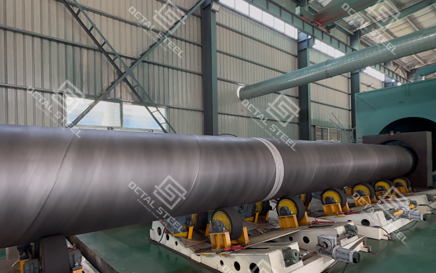

SSAW (Spiral Welded) Pipe Line

For high-efficiency production of long-length spiral pipes, we supply:

| Process Stage | Key Equipment | Main Function & Standards Supported |

|---|---|---|

| Coil Preparation | Automatic uncoiler + leveller + edge milling + strip joining | Perfect strip alignment, weld-ready edges (API 5L, ASTM A252) |

| Spiral Forming | Three-roll forming mill with adjustable forming angle (30°–70°) | Precise helix control, OD range 219–3048 mm |

| Welding | Internal & external multi-wire (up to 4+4) SAW stations + flux recovery system | Full-penetration welds, high deposition rate, qualified to PSL2 |

| Online Quality Control | Real-time seam tracking + ultrasonic weld monitoring | 100 % weld inspection during production, meets DNV-GL requirements |

| Cut-off & End Finishing | Flying cut-off saw + end facing + hydraulic rounding unit | Clean square ends, bevel 30°±5°, ready for field welding |

| NDT & Hydrostatic Testing | Full-body offline UT + high-pressure hydrostatic tester (up to 500 bar) | Complete integrity verification, automatic weight & length record |

| Material Handling | Roller conveyors + transfer cars + automatic stacking system | Safe handling of 18 m+ pipes, reduces surface damage |

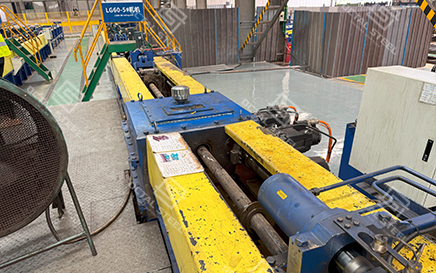

ERW (High-Frequency) Pipe Line

For small and medium diameters, we provide high-frequency ERW straight-seam pipe mills, including:

| Process Stage | Key Equipment | Main Function & Standards Supported |

|---|---|---|

| Coil Preparation | Uncoiler + precision slitting + strip accumulator + automatic strip joining | Continuous feeding, perfect strip edge alignment (API 5L, ASTM A53) |

| Forming | Cage forming + fin-pass stands with quick-change cassettes | Accurate roundness, OD range 21.3–660 mm (½″–26″) |

| Welding | Solid-state high-frequency welder (200–800 kW) + impedance roller | Full-penetration weld at speeds up to 120 m/min, qualified to PSL2 |

| Bead Removal | Internal & external scarfing system (air or water-cooled) | Clean weld zone, smooth ID/OD surface |

| Seam Heat Treatment | Online induction normalizing furnace | Uniform microstructure, improved toughness & weld ductility |

| Sizing & Straightening | Turk’s head sizing mill + multi-roll straightener | OD tolerance ±0.5 %, straightness ≤ 1:2000 |

| NDT & Hydrotest | Eddy current + full-body UT + hydrostatic tester (up to 500 bar) | 100 % weld & body inspection, meets API 5L PSL2 / ASTM A53 |

| Finishing | Flying cut-off, end beveling/threading, bundling & marking | Ready for immediate shipment or coating |

This line covers ASTM A53, API 5L, EN 10219, water and gas pipes, structural hollow sections and other low/medium-pressure applications.

Seamless Pipe Line (Hot Rolling & Finishing)

For seamless pipe projects, we can design and supply the key equipment for:

| Process Stage | Key Equipment | Main Function & Standards Supported |

|---|---|---|

| Billet Preparation | Walking-beam heating furnace + billet centering & transfer system | Uniform heating 1250–1280 °C, precise centering for piercing |

| Piercing | Mannesmann two-roll cross piercing mill or cone-type piercer | Hollow shell creation, OD 60–220 mm, wall 5–30 mm |

| Elongation & Wall Reduction | Mandrel mill (5–8 stands) or retained-mandrel + plug mill | OD range 21.3–660 mm, wall 2.5–70 mm, meets API 5CT / ASTM A106 |

| Sizing & Finishing Rolling | Stretch-reducing mill (SRM) 18–28 stands + de-tenser | Final OD tolerance ±0.5 %, wall ±8 %, perfect roundness |

| Cooling & Straightening | Cooling bed + 9-roll rotary straightener | Straightness ≤ 1:2000, controlled cooling for microstructure |

| Heat Treatment | Walking-beam normalizing / Q&T furnace + water quench | Full N80Q, P110, Q125, 13Cr Q&T capability |

| NDT & Testing | Full-body UT + EC + hydrostatic tester (up to 700 bar) | 100 % inspection, meets API 5CT PSL2/3, EN 10204 3.2 |

| Finishing Line | Cut-to-length saw + CNC beveling + threading + marking | Ready for premium connections and immediate shipment |

The seamless line is suitable for boiler tubes, OCTG, high-pressure pipe and high-temperature alloy pipe production.

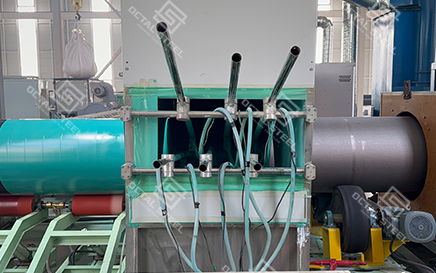

Anti-Corrosion Coating & Lining Lines

To complete the production chain, Octal Steel also supplies external and internal coating lines matched to the pipe mills:

| Process Stage | Key Equipment | Main Function & Standards Supported |

|---|---|---|

| Surface Preparation | Closed-cycle shot-blasting + dust collection + induction pre-heating | SA 2.5 cleanliness, surface temperature 40–60 °C for perfect adhesion |

| FBE Primer | Electrostatic powder spray guns + fluidized bed system | 350–600 μm uniform FBE layer, meets CSA Z245.20, NACE standards |

| Adhesive & PE/PP Layer | Extruder + T-die for adhesive + side-wrap PE/PP extrusion | Total 2.5–4.5 mm 3LPE/3LPP, peel strength ≥ 250 N/cm at 23 °C |

| Water Quenching & Cooling | Closed-loop water quench tunnel + air cooling section | Rapid cooling, prevents PE crystallization damage |

| Holiday Detection | DC high-voltage holiday detector (25 kV adjustable) | 100 % pinhole-free guarantee, meets NACE SP0274 |

| Internal Coating (Optional) | Internal blast + liquid epoxy / FBE spray lance system | 300–500 μm internal lining for potable water or flow efficiency |

| Final Inspection & Handling | Automatic marking, thickness/adhesion test station + pipe transfer system | Full QA report per pipe, ready for immediate shipment |

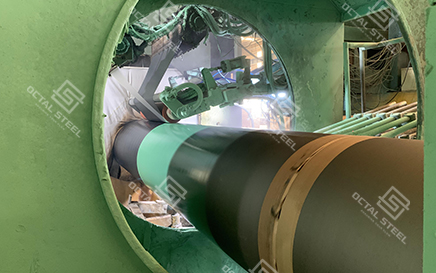

3LPE Coating Production Line (External Pipe Anti-Corrosion System)

A 3LPE coating production line is designed to apply a three-layer polyethylene system—Fusion Bonded Epoxy (FBE) primer, copolymer adhesive, and outer PE jacket—to steel pipes for long-term corrosion protection in buried and submerged pipeline service. In Octal’s configuration, the 3LPE coating line is integrated with upstream pipe mills to keep surface condition, temperature control, and line speed consistent, which is critical for coating adhesion and thickness uniformity.

The process starts with closed-cycle shot blasting to achieve SA 2.5 surface cleanliness, followed by induction pre-heating to maintain the steel surface at a controlled temperature window suitable for FBE bonding. The FBE layer is applied by electrostatic powder spray guns or a fluidized bed system, typically producing a uniform epoxy layer in the 350–600 μm range in accordance with ISO 21809 and NACE requirements.

After FBE gelation, the pipe enters the adhesive and PE extrusion section, where a copolymer adhesive layer and PE topcoat are applied through an extruder and T-die system. Total coating thickness is commonly controlled within 2.5–4.5 mm for standard 3LPE systems, with peel adhesion values typically exceeding 250 N/cm at 23 °C, depending on project specification. A closed-loop water quenching and air cooling tunnel stabilizes the PE layer without inducing crystallization damage or residual stress.

Quality control on the 3LPE coating production line is carried out inline. Each pipe undergoes 100% holiday detection using an adjustable DC high-voltage detector (up to 25 kV) to verify pinhole-free coating integrity, followed by thickness measurement, adhesion testing, and visual inspection. Where required, the same line can be configured for internal epoxy or FBE lining, allowing combined external corrosion protection and internal flow-efficiency solutions.

By supplying the 3LPE coating production line as part of a complete pipe manufacturing and finishing package, Octal Steel enables consistent coating performance, traceable inspection records, and coating systems that are ready for pipeline installation without secondary handling or rework.

Why Work with Octal Steel for Complete Lines

-

One package from steel pipe to coating – LSAW, SSAW, ERW, seamless and coating lines designed to work together instead of being pieced together from different suppliers.

-

Process + equipment – We provide not only machines, but also process layouts, equipment selection, utilities list and basic process parameters based on API/ASTM/EN standards.

-

Installation and commissioning support – Supervising installation, start-up, trial production and training for operators and maintenance staff.

-

Experience from real pipe mills – Our solutions are based on mills already running for line pipe, OCTG, piling and coated pipe projects in the Middle East, Asia, Europe and South America.

-

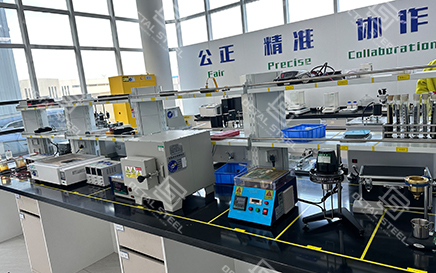

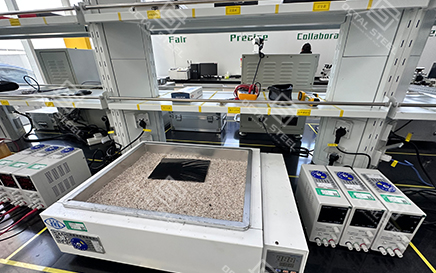

Smart & Digital Steel Pipe Manufacturing Base

Modern pipe mills are moving from simple automation to truly digital and intelligent manufacturing. Octal Steel can help you build not just a production line, but a smart steel pipe manufacturing base with a million-tonne class operation system behind it.

Instead of isolated machines, the whole plant is connected through an integrated MES / SCADA platform:

-

Real-time data from every key station – forming, welding, heat treatment, NDT, hydrotest and coating all feed live data into one system. Production speed, welding current, temperatures and coating thickness are monitored and adjusted on the fly.

-

Full-process digital traceability – each pipe carries its own digital record: heat number, forming parameters, NDT results, hydrotest pressure, coating data. This supports API / ASTM / EN / GB standards and makes third-party audits much easier.

-

Smart production planning and scheduling – the system can balance orders, grades and sizes across the line, helping you run a competitive million-tonne operation with fewer bottlenecks and higher line efficiency.

-

Data-driven quality and R&D – quality trends and process data are stored and analyzed, so your technical team can optimize welding procedures, coating recipes and heat-treatment curves instead of relying only on experience.

For investors and plant owners, this means the new mill is not just “automated” on paper, but truly upgrades your digital manufacturing capability and technical level. You get a plant that can produce competitive steel pipe at scale, with the kind of transparency, stability and efficiency that modern pipeline and energy projects expect.

-