Chrome Moly Pipe

Supply Range of Diameters: 1/2” to 26”

Range of Thickness: SCH 10 to SCH 160

Ends Type: Beveled ends, Plain ends

Range of length: 20FT, 40FT or customized

Protection Caps in plastic or iron available

Surface: Natural, Varnished, Black painting, 3PE, FBE, etc

Chrome Moly pipe, short for chromium-molybdenum alloy steel pipe, is engineered by adding controlled amounts of chromium (Cr) and molybdenum (Mo) into the steel matrix. Chromium contributes to enhanced oxidation and corrosion resistance, while molybdenum improves overall strength, toughness, creep resistance, hardenability, and high-temperature stability. The synergy of these alloying elements makes chrome moly steel one of the most reliable materials for high-pressure and high-temperature services, where ordinary carbon steel would fail.

Widely manufactured under specifications such as ASTM A335 (seamless ferritic alloy-steel pipe for high-temperature service) and ASTM A182 (forged alloy fittings and flanges), chrome moly pipes are essential in power plants, refineries, petrochemical plants, and boilers. Their ability to withstand extreme thermal cycles, aggressive media, and mechanical stress ensures long-term integrity in environments where safety and reliability are paramount.

Key Features of Chrome Moly Pipe:

- Material Composition:

- Typically made from alloy steel with a composition that includes approximately 0.5% to 0.8% chromium and 0.1% to 0.5% molybdenum.

- Strength and Durability:

- Chrome moly pipes are known for their high tensile strength and ability to withstand extreme conditions, making them ideal for high-pressure applications.

- High-Temperature Resistance:

- These pipes maintain their strength and structural integrity at elevated temperatures, making them suitable for use in power plants, refineries, and other industrial settings.

- Corrosion Resistance:

- The addition of chromium provides enhanced resistance to oxidation and corrosion, extending the lifespan of the pipes in harsh environments.

- Weldability:

- Chrome moly pipes can be welded using standard welding techniques, allowing for flexible installation and repair options.

Applications:

- Oil and Gas: Used in pipelines and equipment for transporting oil and gas.

- Power Generation: Commonly found in boiler systems and heat exchangers.

- Chemical Processing: Employed in the transport of chemicals and other industrial fluids.

Mainly standard of Chrome Moly Pipe:

ASTM A335 for Seamless, Common use grades in P11, P22, P5, P9, P91

ASTM A691 for Welded, Corresponding to 1-1/4CR, 2-1/4CR, 5CR, 9CR, 91

ASTM A335 Standard Specification

The ASTM A335 standard—also known as Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service—covers seamless alloy steel pipes intended for use in high-temperature and high-pressure environments. This specification includes both nominal wall thickness and minimum wall thickness requirements, ensuring dimensional consistency and mechanical reliability across different pressure classes and design codes.

Pipes manufactured under ASTM A335 must be capable of bending, flanging, and other forming operations without compromising structural integrity. In addition, they must demonstrate excellent performance in fusion welding, making them suitable for critical fabrication processes in boilers, heat exchangers, superheaters, and petrochemical installations. By setting strict chemical composition limits and mechanical property requirements, ASTM A335 ensures that pipes provide creep strength, oxidation resistance, and thermal stability necessary for continuous service at elevated temperatures.

The most common grades covered by ASTM A335 include P1, P5, P9, P11, P22, P91, and P92, each with specific alloying elements tailored to different operating conditions. For example, P22 is widely used in power generation piping systems due to its balance of strength and weldability, while P91 provides superior creep resistance for ultra-supercritical boiler applications.

ASTM A335 Grades P11, P22, P91, P92 are prevalent grades for the power industry, and P5 or P9 pipe used for refinery processing.

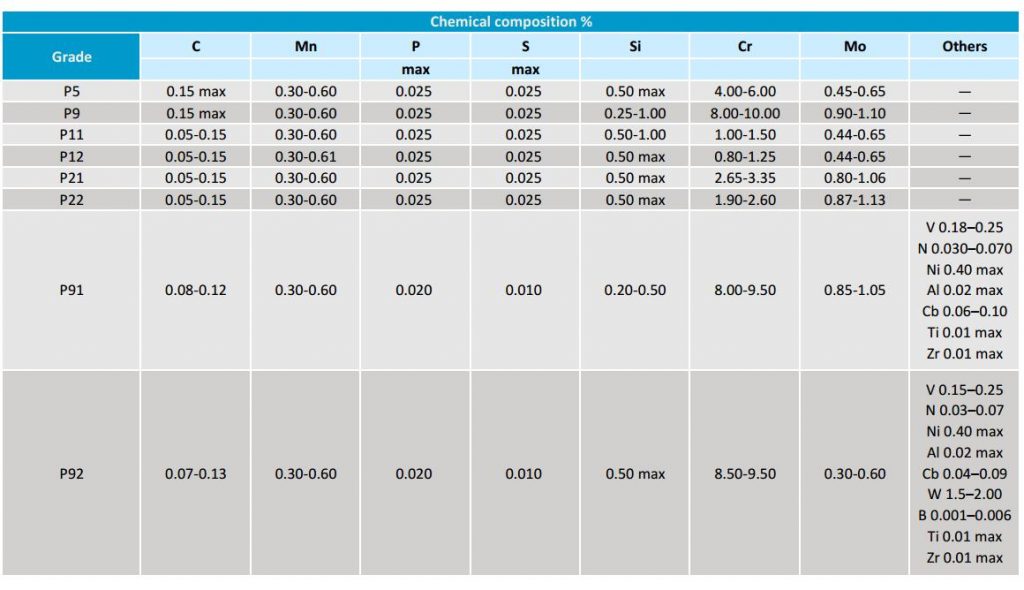

Chemical Composition

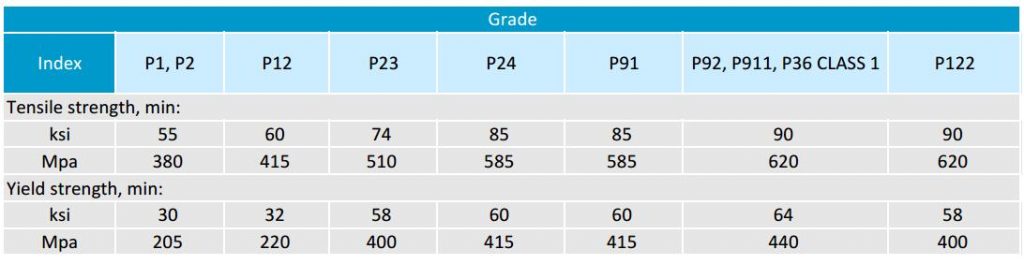

Mechanical Properties

ASTM A691 Standard Specification

ASTM A691 specification covers carbon and alloy steel pipe, electric-fusion-welded with filler metal added, fabricated from pressure-vessel-quality plate of several analyses and strength levels and suitable for high-pressure service at high temperatures. Heat treatment may or may not be required to attain the desired mechanical properties or to comply with applicable code requirements. Supplementary requirements are provided when additional testing or examination is needed.

Mechanical Requirements

Tensile Test – Transverse tensile properties

Transverse Guided Weld Bend Tests

Hydrostatic pressure test classes X2 and X3 pipe shall be tested in accordance with Specification A530/A530M.

Charpy V-Notch Test for pipe with nominal wall thickness of 1/2in 13mm and greater.

Hardness tests

Metallography

Magnetic Particle Examination of base metal and weld metal

Liquid Penetrant Examination of base metal and weld metal

Ultrasonic Test

ASTM A691 Permissible Variations

Outside diameter +/- 0.5%.

Out of roundness – The difference between major and minor outside diameters 1%.

Alignment – Using a 10-ft 3m straightedge placed so that both ends are in contact with the pipe, 1/8in. 3mm.

Thickness – Minimum wall thickness at any point in the pipe shall not be more than 0.01 in 0.3mm under the specified nominal thickness.

Lengths with unmachined ends shall be within -0, +1/2 inch, 0 +13mm of that specified. Lengths with machined ends shall be as agreed between manufacturer and purchaser.

Dimension range:

ASTM A691 covers pipe OD in 16inch and above, wall thickness up to 3inch, 75mm.

Equivalent Material for Fittings, Flanges, Plates

Pipe fittings standard: ASTM A234 WP22

Flange Standard: ASTM A182 F22

Steel Plate Standard: ASTM A387 Grade 22/ ASME SA387 Grade 22

Welded pipe standard: ASTM A691 2-1/4 CR

P22 pipe material has high toughness and high wear and tear resistance, it could be used to manufacture pipe fittings like elbow, tee, reducers in ASTM A234 WP22 chrome moly pipe fittings.

Our Supply Range:

Standard and Grades for Seamless: ASTM A335 / ASME SA335 Grade P11, P22, P5, P9, P11

Standard and Grades for Seamless: ASTM A691 for Welded, Corresponding to 1-1/4CR, 2-1/4CR, 5CR, 9CR, 91

Material types: Chrome Moly Pipe

Manufacturing types: Seamless pipe by hot rolled or cold drawn

Sizes: 1/2” to 24”

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

Surface treatment: Polished, Varnished, 3PE, FBE

Ends: PE (Plain End), BE (Beveled Ends)