Stainless Steel Pipe and Tube

Octal supply below ranges for the stainless steel pipe and tube:

Standards: ASTM A321, ASTM A213, ASTM A269, ASME SB677

Duplex stainless steel pipe standards: ASTM A789/ ASME SA 789. ASTM A790/ ASME SA 790

Material: AISI 304, 304L, 316, 316L

Outer Diameter: 5.8 – 508mm

Wall Thickness: 0.3 – 50mm

Stainless steel pipes and tubes are engineered by enriching the steel matrix with nickel (Ni) and chromium (Cr) to achieve exceptional corrosion resistance, strength, and durability across diverse environments. Among the most commonly used stainless grades are 304 / 304L and 316 / 316L, offering a balance of ductility, weldability, and chemical resistance. These products are manufactured in compliance with industry standards such as ASTM A312, A213, A270, among others, ensuring reliable performance in critical applications.

Because stainless steels provide a passive oxide film enriched by Cr and stabilized by Ni, they resist oxidation, pitting, and crevice corrosion when exposed to chemicals, seawater, and elevated temperatures. As a result, stainless steel pipes and tubes find their way into chemical processing, food & beverage, pharmaceutical, desalination, marine, and high-purity systems. Their versatility across demanding service conditions makes them a preferred material choice when longevity and low maintenance are priorities.

What is stainless steel pipe

Stainless steel pipe is a kind of hollow and longitude steel, economic steel section is round shape. Stainless steel pipe and tube has been widely used in oil, chemical industry, medical, food, light industry, equipment and apparatus and structural parts etc. In additional, when twisting and anti-twist intensity is equal, stainless steel is more lighter, so it used in equipment parts and projects structural. Also used to produce all kinds of conventional weapons, barrel, shells and so on. This kind of pipes divide into: stainless steel seamless pipes and stainless welded pipes. According by manufacturing process can divided into following basic types: hot-rolled, extrusion, cold-circular, hexagonal, equilateral triangle, octagonal and other special-shaped stainless steel pipe

Octal offers super austenitic stainless steel pipe and tube in different material standards and grades.

Common standards explanation

ASTM A312

ASTM A213

ASTM A269

ASTM A789/ASME SA789

ASTM A790/ASME SA790

ASME SB677

ASTM A312 – For high temperature and general corrosive

The ASTM A312 standard specification for seamless, welded, and heavy cold worked austenitic stainless steel pipes. stainless steel pipe and tube is widely in sulfuric acid storage tank in the phosphate fertilizer industries. Fluorosilicic /acid reactor phosphoric acid plant; Chlorate Crystallizer in the production of fertilizer; Ventilation system in pharmaceutical factory; Solvent recovery filter, condenser, pipeline; Bleaching equipment and filter in the pulp and paper industry; pipelines and water collecting system in offshore platforms; multi-stage flash distillation, low-temperature multi effect desalination; seawater condenser for power plant and so on.

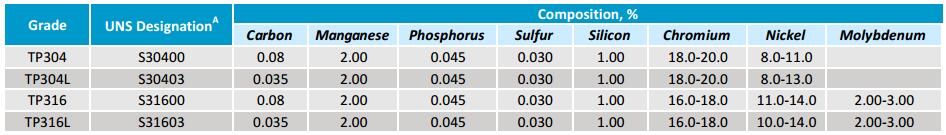

Chemical Composition for ASTM A312 TP304 and TP316

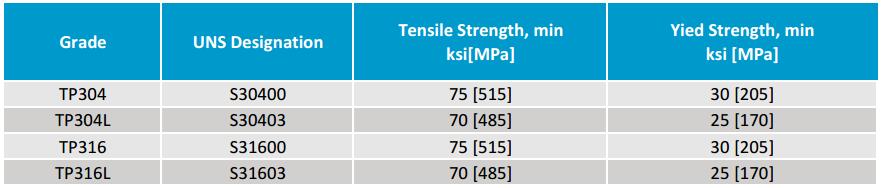

Mechanical Properties

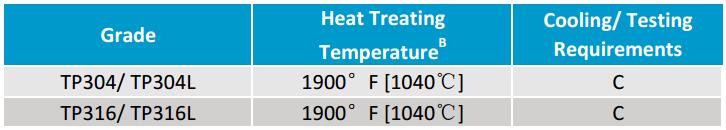

Heat Treatment Methods

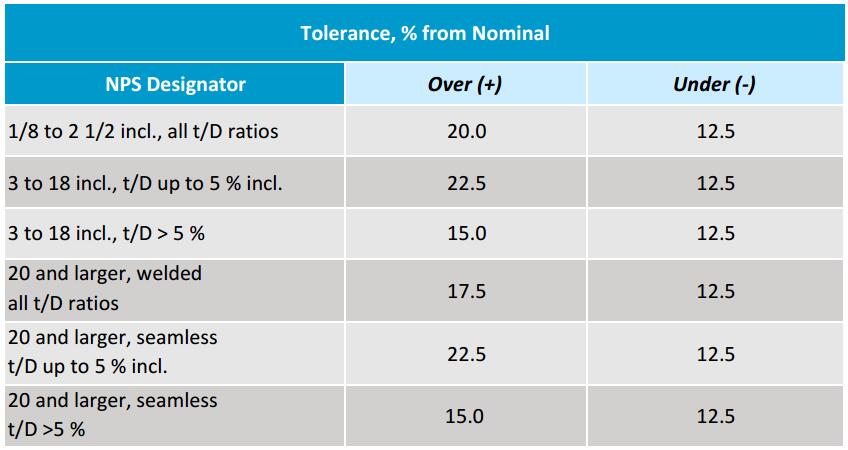

Permitted Tolerance in Wall Thickness in ASTM A312

Where:

t = Nominal Wall Thickness

D = Ordered Outside Diameter

ASTM A213 stainless tubing for boiler, heat exhanger

The ASTM A213 covers the seamless ferric carbon steel and austenitic alloy stainless steel tube, applied for boiler, superheater, and heat-exchanger steel tubes.

ASTM A269 – General use stainless tubing

The ASTM A269 covers the stainless steel tubes for common application in seamless and welded.

ASME SB677 – Extremely corrosive resistance

ASME SB677 specification covers the UNS N08904 (904L), UNS N08925, UNS N08926 (alloy 926), in seamless, of cold-drawn, and hot finished steel pipe and steel tube for the extremely corrosive services. The standard includes the material in carbon steel, and ferritic alloy steel, and austenitic stainless steel pipes and tube, 6% molybdenum alloy stainless seamless pipe and tube.

ASTM A789 – Duplex stainless tubing

ASTM A789/ ASME SA789 covers seamless and welded ferritic/austenitic stainless steel tubing for general services. The standard also applied to duplex stainless steel tube material. All tubes in this standard shall be furnished with heat-treated condition according to specified temperature and quench conditions. When the final heat treatment is in a continuous furnace, or when heat treated condition is obitained directly by quenching after hot forming, the number of tubes of same size and from the same heat lot shall be determined from the prescribed sizes of the tubes.

ASTM A790 – Good resistance on stress corrosion cracking

ASTM A790/ ASME SA790 is standard specification for seamless and welded ferritic/austenitic stainless steel pipe. Including duplex stainless steel pipe material. The standard specification mainly covers seamless and longitudinal weld ferritic/austenitic steel pipe, that applied intended for general corrosive services, with particular emphasis on resistance to stress corrosion cracking. This kind of pipe shall be manufactured by seamless or automatic welding process, without adding filler metal in the welding processes. Heat analysis shall be made to determine the percentages of the chemical elements specified. Tensile test, hardening test, flattening test, hydrostatic tests and nondestructive test shall be performed to the specified requirements.

Stainless steel pipe and tube sizes and grades

Octal supply range for the stainless steel pipe and tube:

Standards: ASTM A321, ASTM A213, ASTM A269, ASME SB677

Duplex stainless steel pipe standards: ASTM A789/ ASME SA 789. ASTM A790/ ASME SA 790

Material: AISI 304, 304L, 316, 316L

Outer Diameter: 5.8 – 508mm,

Wall Thickness: 0.3 – 50mm

Manufacturing types and processes

1. Seamless Hot Rolling Processes

Round Pipe Billet → Heating → Perforation → Three Roll Skew Rolling, Continuous Rolling or Extrusion → Off Pipe → Sizing (Or Reducing Diameter)→ Cooling → Billet → Straightening → Water Pressure Test ( Or Flaw Detection) → Marking → Storage

2. Seamless Cold Rolling (Cold drawn) Processes

Round Pipe Billet → Heating → Perforation → Head → Annealing → Pickling → Oil (Copper) → Multi Pass Drawing (Cold Rolling) → Billet → Heat Treatment → Straightening → Water Pressure Test → Marking → Storage

3. Longitudinal welding (Straight seam welding) processes

Including ERW, EFW.

Corrosion Resistance of Stainless Steel Tube and Pipe

Corrosion resistance performances is the key feature for stainless tube. The commonly used types of steel involve ferritic and martensitic steel, that are predominantly made by adding chromium and manufactured through heat-treatment or to be annealed. There are austenitic stainless steel tubing products that are rich in chromium and nickel and they offer better resistance levels when used under the same conditions as compared to martensitic or ferritic materials.

Common types of stainless steel tubing pipe

As Stainless steel tubing applied in different industries and applications, so what are the common types of the Stainless tubing pipe. Here are below:

• Stainless steel tubing in high pressure use

• Sanitary tubing

• Mechanical use

• Stainless steel tubing for structural and construction

• Boiler stainless steel tube, heat exchanger

• Aircraft tubing

• Oil and gas industries, Petroleum cracking process, Casing and tubing

• For pipelines, liquid transmission

Stainless Pipe for High Pressure

Generally manufactured using solid chromium or a combination of nickel and chromium, including manufactured in seamless and welded stainless pipe. Such as electric fusion welded pipe (ERW) that find application in high-pressure usage; Large diameter stainless steel pipe (in welded and seamless) in case of corrosion of high-temperature applications.

Stainless Sanitary Tubing

Sanitary tubing usually in stainless material and referred standards is ASTM A270. In case the pipe or tube coming in direct contact with sensitive products like food, water, or drink, it is what we called sanitary tube. In these situations, sanitary tubing has good performances of corrosive resistance, no tarnish, and is easy to clean.

Based on the usage, different levels of tolerance (diameters and thickness) shall be applied as in ASTM A270.

Stainless steel tubing for mechanical usage

When the usage is in cylinders, bearings or other hollow formed parts, there is a usage for mechanical purposes. The tubing that is available can be manipulated easily and it results in a wide range of cross-sectional shapes, or even shapes that are round or the ones that need to fit in the cross-section. It finds widespread usage in case of mechanical tubing.

Technical Summary

For systems where corrosion resistance, hygiene, and durability are paramount, stainless steel pipes and tubes deliver unmatched performance. By choosing materials such as 304 / 304L or 316 / 316L, and adhering to trusted standards like ASTM A312, A213, and A270, applications across industry can achieve longevity, reduce maintenance, and ensure process integrity.

Octal Steel offers a comprehensive portfolio of stainless steel pipes and tubes with full certification, traceability, and controlled metallurgy. Whether required for chemical plants, marine systems, food & beverage lines, or high-purity installations, our products are engineered to meet demanding standards and deliver dependable performance. Partner with Octal Steel for stainless solutions that combine material science, manufacturing excellence, and real-world durability.

Social Share