FBE coating

Scope: defines FBE coating requirements for pipe coating by service environment and installation damage exposure.

Process window: blast clean (Sa 2½ / NACE No. 2, 50–100 μm), preheat 180–250°C, electrostatic FBE powder coating, fusion bonding cure.

Acceptance: DFT targets, holiday (jeep) testing, cutback/end protection, repair limits, and retest closure.

Standards: ISO 21809-2, AWWA C213, AWWA C550, CSA Z245.21 (project-defined), translated into inspection and documentation evidence.

Traceability: links pipe identification, coating lot/powder batch, inspection and repair logs, and packing list line items.

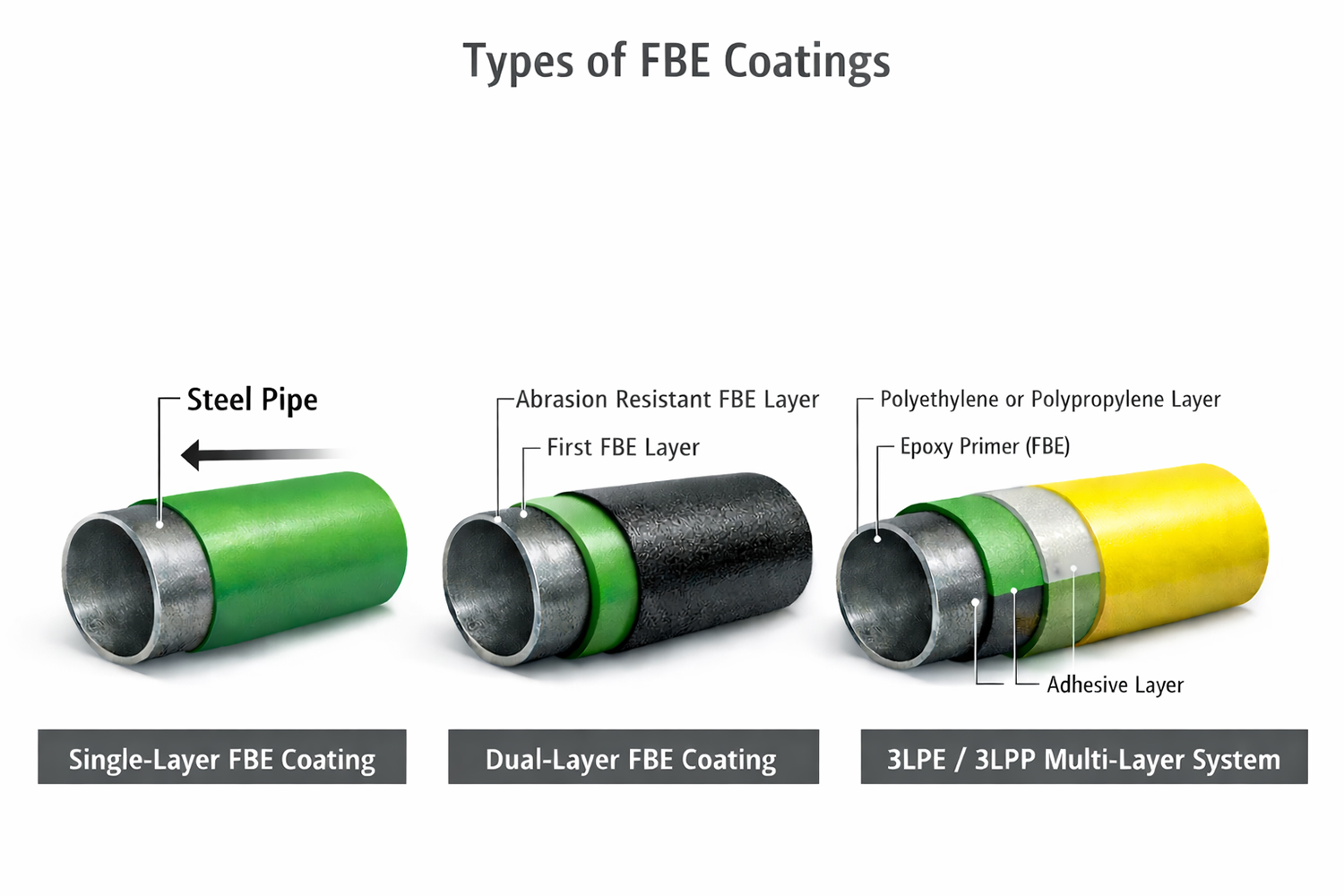

System options: single-layer FBE, dual-layer abrasion-resistant FBE, or 3LPE/3LPP (FBE as epoxy primer), plus epoxy paint boundaries for field joints and localized repairs.

Overview

FBE coating is a fusion bonded epoxy coating applied to preheated steel as an epoxy powder, where the powder melts, flows, and cures into a continuous cross-linked film—creating an electrically insulating, moisture-resistant corrosion barrier for long-term pipe coating in buried, submerged, or chemically aggressive service. This heat-driven melt-and-cure bonding mechanism is known as fusion bonding: at typical application temperatures of about 180–250°C (356–482°F), the FBE powder melts into a liquid, wets the hot steel surface, and then chemically cross-links as it cures into a continuous film, which is why the coating is called fusion bonded epoxy coating.

In project language, FBE powder coating emphasizes the powder-applied process, while FBE coating describes the final cured barrier on coating pipes, fittings, and valves. In many specifications, “fusion bonding” describes the heat-assisted formation of a bonded epoxy film through melt, wetting, and chemical cross-linking during cure.

As an external coating, FBE is often selected because it combines corrosion isolation with inspection-based acceptance, allowing coating integrity to be verified after handling and installation activities.

Typical Applications

FBE coating is specified where external corrosion protection must remain verifiable after handling, stringing, and installation, and where coating performance is managed through defined DFT, continuity (holiday) testing, cutback control, and repair/retest closure.

• Oil & gas pipelines: applied to transmission and gathering lines where corrosion control relies on an electrically insulating barrier that remains continuous under soil moisture and CP exposure. Performance is typically achieved by controlling preheat and DFT to form a uniform film, protecting cutbacks for field joints, and verifying continuity by holiday (jeep) testing after yard handling and stringing; abrasion-resistant or dual-layer FBE is commonly selected for crossings where mechanical damage risk is higher.

• Water and sewage pipelines: specified to isolate steel from wet soil and groundwater exposure and to keep coating acceptance measurable on water pipe and fittings. The coating effect is managed through surface preparation quality, DFT distribution, and holiday testing to prevent pinholes that can become localized corrosion initiation points; repair rules and retesting are used to keep coating continuity consistent across buried sections and fittings with geometry changes.

• Fittings & valves: used on bends, tees, reducers, and coated valves where edges, radii, and transitions are frequent thin-film risk areas. Coating effectiveness is achieved by controlling deposition around geometric transitions, verifying DFT in high-risk zones, and applying holiday testing with repair/retest closure so the coating remains continuous through handling and installation; documentation often ties each component ID to inspection logs for acceptance.

• Rebar (project-dependent): applied to reinforcing bars where corrosion protection is achieved by forming a continuous epoxy barrier that limits chloride and moisture access in concrete exposure conditions. Performance is typically managed by coating continuity control and damage repair practices during transport and placement, so coating defects do not become preferential corrosion sites once embedded.

Pipe Coating Specification Scope and Acceptance Items

A practical FBE coating scope typically aligns procurement fields with engineering acceptance criteria and is executed under a project-approved inspection and test plan (ITP).

Specification snapshot for pipe coating RFQs

| Item | Typical RFQ / ITP Definition | Acceptance Focus |

|---|---|---|

| Coating system | Single-layer FBE coating, or FBE as the epoxy base layer within multi-layer systems | System definition aligns with service and handling risks |

| Surface preparation | Blast cleanliness + surface profile + contamination controls | Adhesion stability and repeatability |

| DFT / thickness | Target range + min/max criteria + gauge method | Thickness distribution and traceable readings |

| Holiday / porosity test | Test voltage criteria + repair and retest rules | Continuity of corrosion barrier |

| Pipe ends / cutback | Cutback length + bevel/end protection + handling protection | Field joint compatibility and end-condition control |

| Repairs | Repair method + repair material qualification + re-inspection scope | Closed-loop repair records and retest evidence |

| Traceability | Pipe ID to coating lot/powder batch + inspection logs + packing list mapping | Documents close without re-submission cycles |

A typical coating specification may reference industry standards (project-dependent) and owner requirements, and is implemented through an ITP that defines process controls and acceptance evidence across production lots. FBE coating scopes are commonly aligned with recognized standards to keep system definition, inspection methods, and release documentation consistent across project lots. ISO 21809-2 is often referenced for external pipeline coatings using single-layer fusion bonded epoxy; AWWA C213 is commonly used in water pipeline programs for FBE coatings/linings on steel pipe and fittings; AWWA C550 is frequently referenced when the scope includes epoxy-coated valves and hydrants; and CSA Z245.21 is used in Canadian programs for external coatings on steel pipe. In RFQs and ITPs, these references typically translate into measurable acceptance items such as DFT mapping, holiday (jeep) testing, repair/retest closure, cutback/end controls, and traceability linked to pipe identification.

Application Process (Surface Prep, Preheat, Powder, Fusion & Cure)

FBE coating performance starts with surface condition and thermal control, then depends on how the powder forms the final film.

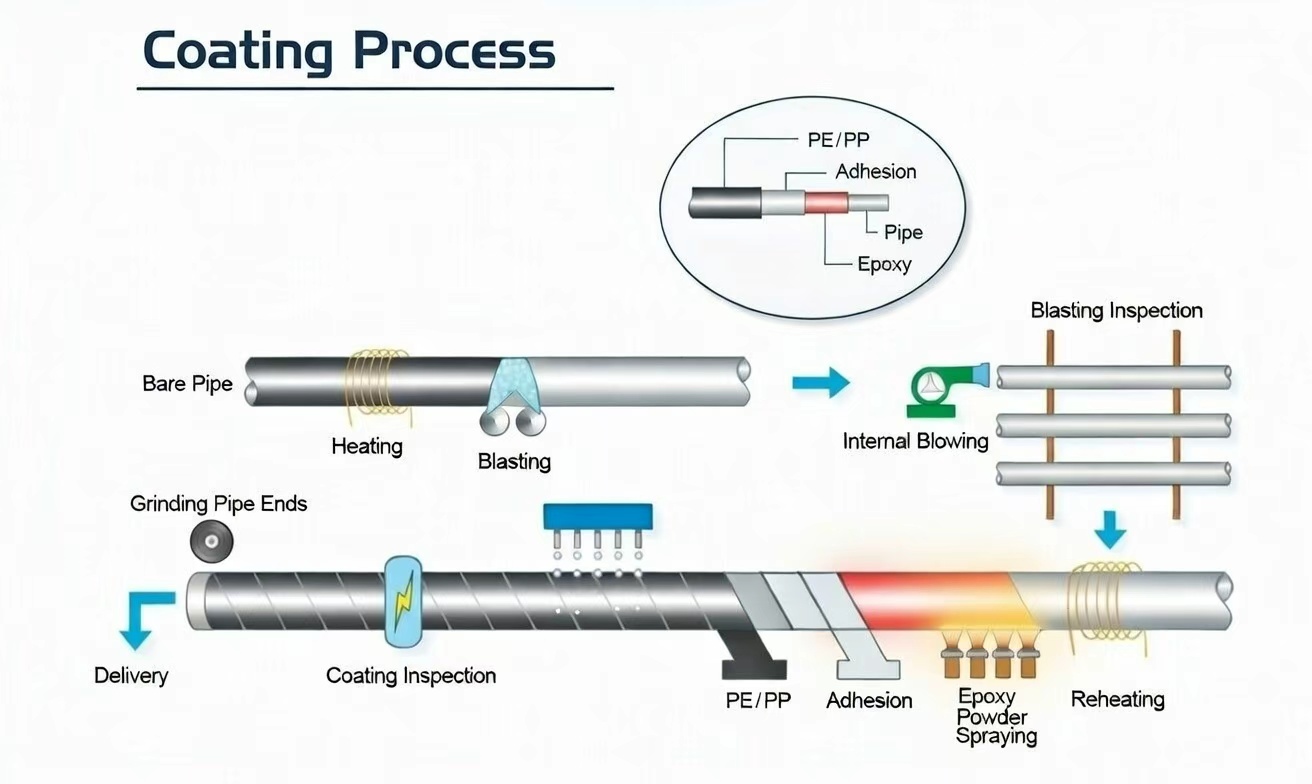

⒈ Surface preparation: abrasive blasting removes rust, mill scale, oil/grease residue, and embedded contaminants, then establishes a controlled surface profile for mechanical anchoring. Typical alignment is Sa 2½ or NACE No. 2 with a 50–100 μm profile range; acceptance is commonly supported by visual cleanliness checks, surface profile readings, and confirmation that dust and soluble contamination are controlled before heating.

⒉Preheating: heating brings the steel into a stable thermal window (typically 180–250°C) so the powder can fully melt, wet the steel, and cure without under-cure or dry spray. A consistent temperature across pipe OD and along length improves film uniformity and reduces edge/end variability, especially around cutback zones and pipe ends where heat loss can be higher.

⒊Electrostatic powder application: charged epoxy powder is applied by electrostatic spray to achieve even coverage around the circumference and along the pipe body. On contact with the hot surface, the powder melts and flows to fill the blast profile and form a continuous film; deposition settings and line speed are tuned to reach the target DFT window while avoiding thin areas at weld seams, edges, and geometric transitions.

⒋Cure and cooling: after application, the coating chemically cross-links using residual heat (or controlled post-heat on some lines) to develop final hardness, adhesion, and chemical resistance. Cooling is then managed to stabilize the coating prior to inspection—water quench is used in some facilities, while other lines use staged air/water cooling—followed by holiday (jeep) testing to detect pinholes, voids, or discontinuities in the FBE film, with any indications repaired and re-tested until the coated surface meets the specified continuity criteria and is traceable to the pipe identification.

This fused film acts as an electrically insulating barrier, helping limit moisture contact and external corrosion drivers on the steel surface.

Key Performance Attributes

A fusion bonded epoxy coating is selected because its performance characteristics align with both corrosion control and inspection-based acceptance.

• Corrosion protection: a dense barrier against water, soil moisture, and many external chemical exposures encountered in buried service.

• High adhesion: strong bonding to the steel substrate, supporting coating integrity under handling and controlled installation practices.

• Chemical resistance: stable performance against a range of corrosive substances in the external environment, defined by project exposure conditions.

• Cathodic disbondment resistance: reduced tendency for coating separation under cathodic protection exposure when specified and qualified accordingly.

• Toughness and flexibility: durability that helps reduce damage risk during transport, yard handling, field stringing, lowering-in, and back-filling.

• Efficient flow surface: a smooth finished coating surface that may reduce friction effects in pipeline operation, depending on system design and service conditions.

System Interfaces: Epoxy Primer and Epoxy Paint

Coating documents often include multiple epoxy terms because different layers and different work locations require different application methods.

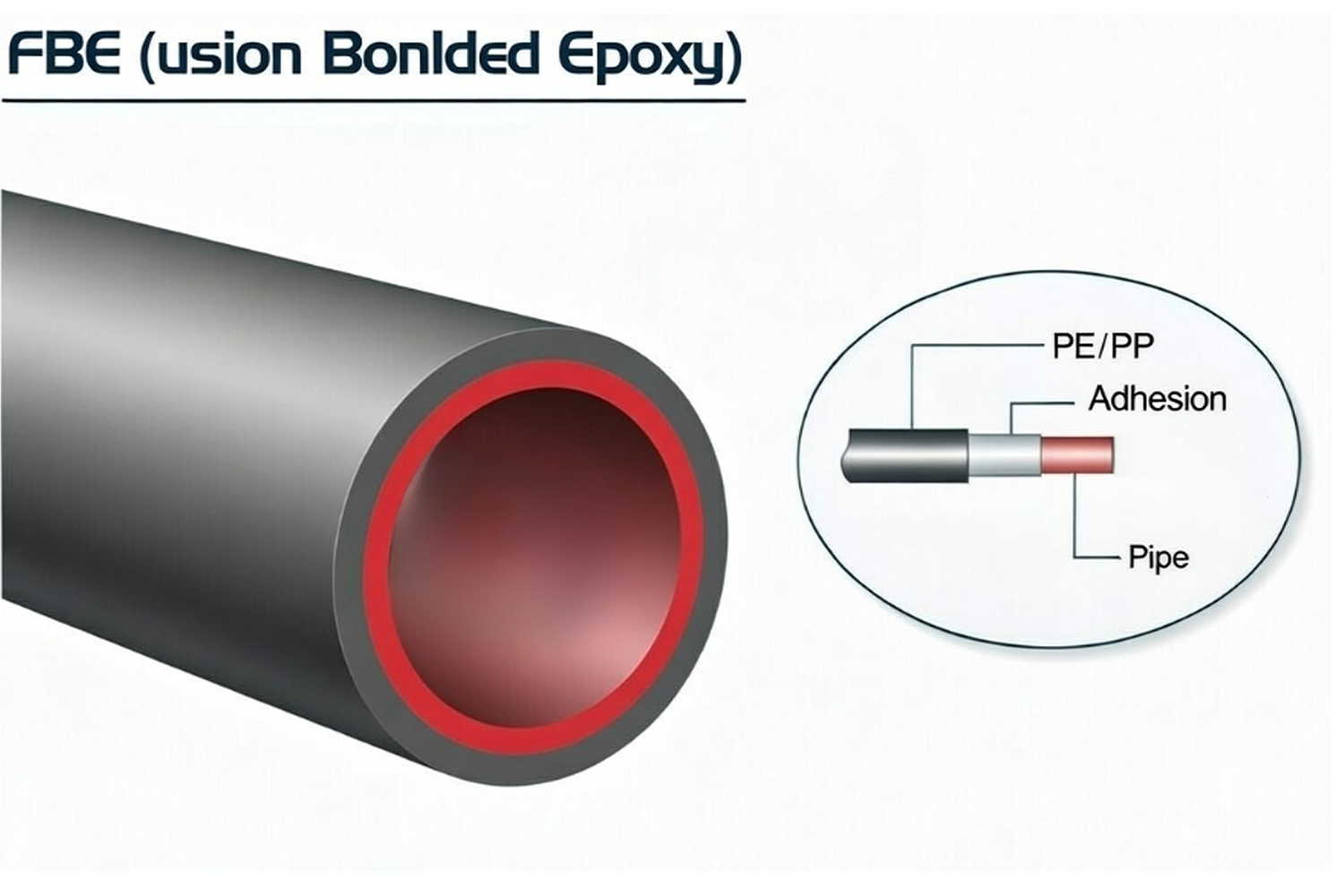

• Epoxy primer: in multi-layer external coating systems (for example, polyolefin systems), the base epoxy layer is commonly described as an epoxy primer because it anchors the system to blast-cleaned steel and provides the primary corrosion barrier function. In many production lines, FBE serves as that epoxy primer layer within the full system structure.

• Abrasion-resistant dual-layer FBE (project-defined): where installation damage risk increases at crossings (roads, waterways, and congested utilities), dual-layer or abrasion-resistant FBE systems may be specified to provide additional mechanical protection beyond standard single-layer FBE coating.

• Epoxy paint: in field joint areas, shop bends, and localized repairs, plant-applied powder fusion is not typically re-applied on site. In these zones, liquid-applied epoxy materials are often specified as epoxy paint for stripe coating, touch-up, or repair work, followed by continuity retesting to close acceptance.

Types and Variations

FBE coating is specified in different constructions depending on mechanical damage risk, moisture barrier needs, and system interfaces on coating pipes.

• Single-layer FBE: a thin-film fusion bonded epoxy coating used for standard external corrosion protection where installation damage risk is controlled by handling and backfill conditions. RFQs typically define the coating as “single-layer FBE coating” with the DFT range, holiday test requirement, cutback length, repair limits, and traceability records aligned to pipe identification.

• Dual-layer FBE: a two-layer FBE construction applied to increase impact and abrasion resistance for mechanically demanding sections such as road/water crossings and high-stress installation areas. RFQs commonly state “dual-layer / abrasion-resistant FBE” and include layer construction intent, mechanical damage resistance focus, continuity (holiday) criteria after repair, and end/cutback handling controls.

• Multi-layer systems (3LPE / 3LPP): FBE is used as the essential anti-corrosion epoxy primer layer bonded to blast-cleaned steel, followed by an adhesive tie layer and a PE/PP outer layer for higher mechanical and moisture barrier performance. RFQs typically specify the system as “3LPE” or “3LPP” and define the epoxy primer (FBE) requirement, layer structure, cutback configuration, repair method boundaries for field joints, and a release dossier that links inspection results to each pipe length or batch.

Inspection and Documentation Package

Typical deliverables include:

⒈ Process and material control records: coating procedure and ITP (project-approved), incoming inspection logs, epoxy powder batch/lot certificates (CoA), batch traceability, storage/shelf-life control, and line process parameters covering blast media control, surface profile targets, and preheat temperature window (180–250°C) used for production.

⒉ Surface preparation and application evidence: cleanliness verification (e.g., Sa 2½ / NACE No. 2 where specified), surface profile readings (e.g., 50–100 μm where specified), preheat temperature readings along the run, and application logs that support repeatability across the production lot and pipe ends/cutback areas.

⒊ Finished-coating inspection reports: DFT results with traceable gauge identification and a defined reading pattern (min/avg/max against the specified range), holiday (jeep) test records stating test voltage criteria, coverage scope, results, and any discontinuities found, plus visual inspection notes for coating condition and end/cutback compliance.

⒋ Repair and retest closure package: a repair register listing defect type, location (by pipe ID and position), repair material/method, cure confirmation (as required), and mandatory re-testing results (holiday re-test and any recheck DFT) until continuity acceptance is met with no open repairs.

⒌ Traceability and release dossier: a traceability matrix that ties pipe marking/ID to coating lot and powder batch, inspection report numbers (DFT/holiday/repair), and packing list line items, supported by calibration certificates for inspection equipment (DFT gauge, holiday detector, temperature instruments) and project-defined qualification/lab records where required (e.g., adhesion, cathodic disbondment, impact/abrasion).

Supply and Project Execution Support

OCTAL supports FBE coating supply by aligning the coating scope with measurable acceptance evidence, so RFQ review, ITP execution, and release approval can be closed on the first submission.

Execution coverage commonly includes:

Scope confirmation: coating system type (single-layer FBE, dual-layer abrasion-resistant FBE, or FBE as epoxy primer in 3LPE/3LPP), DFT window, holiday (jeep) test criteria, cutback length, repair limits, and retest requirements matched to the installation method and field joint interface.

Lot and document control: pipe identification linked to coating lot and powder batch, with DFT readings, holiday test logs, and repair/retest records organized by pipe length or batch and mapped to packing list line items.

Handling protection: cutback and bevel/end protection defined and applied to reduce damage during loading, transport, and yard handling, maintaining end-condition consistency for field welding and joint coating.

Release dossier: a consolidated package that groups coating process records, inspection results, calibration/qualification evidence (project-defined), traceability mapping, and shipment documents in a review-ready structure to minimize re-submission cycles.

FAQ

Q1: What is fusion bonded epoxy coating, and what does “fusion” mean in FBE coating?

A1: Fusion bonded epoxy coating is an epoxy powder coating applied to preheated steel; “fusion” is the powder melting and wetting the hot steel surface, flowing into a continuous film, then curing into a cross-linked epoxy barrier.

Q2: Is there a difference between FBE coating and FBE powder coating?

A2: FBE coating describes the final cured coating on the pipe or component, while FBE powder coating emphasizes the powder material and the powder-application process used to form that coating.

Q3: Which inspection items are typically used to accept FBE coating on coating pipes?

A3: Acceptance commonly focuses on dry film thickness (DFT) distribution, holiday/porosity testing, repair and retest records, cutback/end condition control, and traceability linking pipe ID to coating lot and inspection logs.

Q4: Where do epoxy primer and epoxy paint fit in a pipe coating project that specifies FBE coating?

A4: Epoxy primer commonly describes the base epoxy layer in multi-layer systems where FBE can serve as the primer layer, while epoxy paint is typically used for field joint coating or localized repairs where powder fusion application is not re-applied on site.