Drilling Riser

Drilling Riser, 21″–21½″ ID, providing stability and well control in deepwater operations.

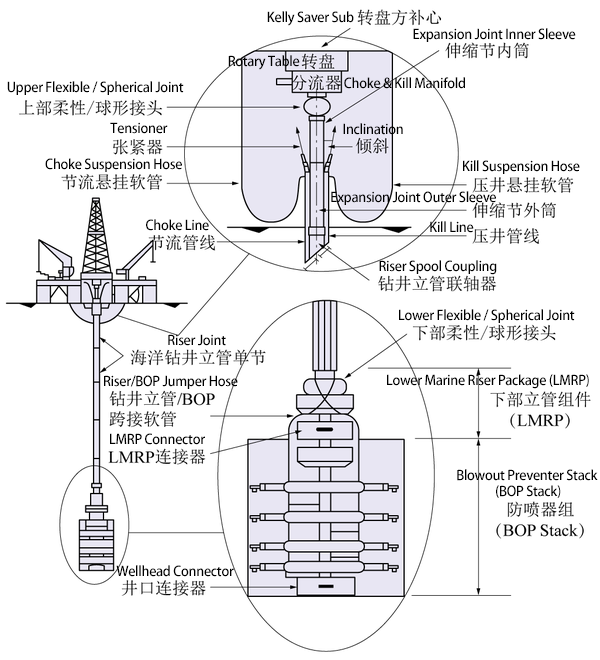

A drilling riser is a critical piece of subsea equipment that connects the subsea wellhead and blowout preventer (BOP) to the surface drilling rig or platform. Unlike conductor pipe, which is a permanent foundation element, the drilling riser functions as a temporary, pressure-containing conduit during drilling operations. Its primary role is to provide a continuous flow path for drilling fluids, cuttings, and pressure control systems between the seabed and the rig.

Drilling risers are essential for deepwater and ultra-deepwater exploration, where water depths often exceed 2,000 meters. In these environments, direct access to subsea wellheads is not possible without a conduit system capable of handling dynamic marine motions, hydrostatic pressures, and fluid returns. Equipped with tensioning systems and advanced sealing technologies, drilling risers ensure safe well control and efficient drilling performance under some of the most challenging offshore conditions.

Drilling Riser Specifications & Functions

The drilling riser is often described as the umbilical cord between the surface drilling unit and the subsea wellhead. Its functions extend beyond providing a simple conduit; it plays a multi-dimensional role in ensuring the safety, efficiency, and controllability of offshore drilling operations: Circulation of Drilling Fluids

The riser provides a continuous annular pathway for drilling fluids to travel from the subsea wellbore back to the rig.

It enables the removal of cuttings, cooling of the drill bit, and stabilization of the wellbore.

In deepwater wells, this circulation function is critical because the mud column must balance formation pressures while maintaining density stability across long vertical distances.

Pressure Control and Well Integrity

- The riser connects the subsea blowout preventer (BOP) stack to the rig’s well control system, enabling surface operators to shut in the well if abnormal pressure conditions occur.

- By housing choke and kill lines along its exterior, the riser also allows operators to control wellbore pressures, circulate out kicks, and inject fluids directly into the wellbore when required.

- This pressure management capability makes the riser a central element of well integrity defense.

Dynamic Flexibility and Motion Compensation

- Offshore rigs are subject to environmental motions from waves, wind, and currents.

- The riser is designed with tensioning systems, flex joints, and buoyancy modules to accommodate vertical heave and lateral offsets.

- These components maintain the riser’s verticality and protect the subsea wellhead from excessive bending or fatigue.

Temporary but Reusable Infrastructure

- Unlike permanent casing strings, the drilling riser is retrieved after the well is drilled.

- With proper inspection, refurbishment, and recertification, riser joints can be reused across multiple wells, making them a cost-efficient and sustainable offshore asset.

Integration with Subsea Systems

- Drilling risers serve as the main structural and hydraulic connection between the rig and subsea BOP.

- They support auxiliary lines (choke, kill, hydraulic, booster) essential for deepwater well control and intervention.

- In effect, the riser becomes a multi-functional conduit for both fluids and control systems.

Manufacturing Standards and Capabilities

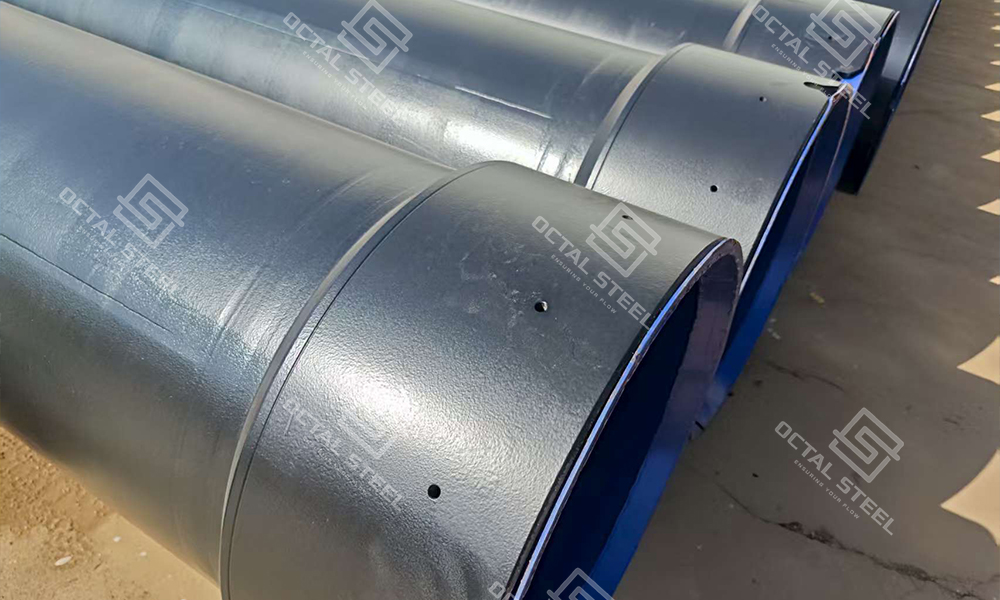

Octal Steel provides drilling risers engineered to withstand deepwater loads, extreme hydrostatic pressures, and harsh marine environments.

-

Material Selection

-

High-strength low-alloy steels with fatigue resistance.

-

Advanced coatings for corrosion protection in seawater immersion.

-

-

Design Options

-

Marine drilling risers with tension joints, flex joints, and buoyancy modules.

-

Internal sealing mechanisms for fluid isolation.

-

API and DNV certified riser systems for global offshore projects.

-

-

Quality Assurance

-

Non-Destructive Testing (NDT) for welds and stress-bearing sections.

-

Fatigue and corrosion testing under simulated seawater conditions.

-

Hydrostatic pressure testing to validate deepwater performance.

-

Difference between Conductor Pipe and Drilling Riser

| Aspect | Conductor Pipe | Drilling Riser |

|---|---|---|

| Function | Permanent casing foundation; stabilizes seabed, isolates seawater, supports wellhead. | Temporary conduit; connects subsea wellhead/BOP to surface rig. |

| Installation Stage | First casing string, installed into seabed. | Deployed after wellhead installation, during drilling. |

| Permanence | Permanent structural part of the well. | Temporary, retrieved after drilling is complete. |

| Operational Scope | Shallow-water structural foundation and stability. | Deepwater circulation, pressure management, and well control. |

| Load Role | Transfers axial and lateral loads to seabed. | Manages dynamic motions via tension systems. |

| Diameter Range | Typically 20″–36″. | Larger riser systems with internal ID often >21″. |

Conclusion of Comparison:

-

Conductor Pipe is the foundation in shallow-water wells, ensuring structural stability.

-

Drilling Riser is the operational conduit in deepwater wells, enabling safe fluid circulation and pressure control.

Together, they form a complementary system, bridging seabed integrity with surface operational control.

Applications of Drilling Risers

Drilling risers are indispensable in offshore drilling projects, particularly where deepwater and ultra-deepwater conditions demand advanced well control infrastructure:

-

Deepwater and Ultra-Deepwater Exploration

-

Applied in water depths often exceeding 2,000 meters, where direct drilling without a riser is not feasible.

-

Essential for projects in frontier basins such as the Gulf of Mexico, offshore Brazil, and West Africa.

-

-

Dynamic Offshore Environments

-

Used in floating rigs, drillships, and semi-submersibles, where platform motions require tensioned riser systems to maintain well control.

-

The riser’s ability to accommodate vessel movement ensures operational continuity even under harsh sea states.

-

-

High-Pressure, High-Temperature (HPHT) Wells

-

Provides secure pressure containment when drilling into challenging reservoirs.

-

Designed to withstand extreme gradients and pressure fluctuations without compromising integrity.

-

-

Integration with Well Control Equipment

-

Interfaces with subsea BOP stacks, enabling emergency shut-in and pressure containment during drilling.

-

Facilitates safe operation of auxiliary lines (choke and kill), which are vital for well intervention and pressure regulation.

-

-

Temporary Well Access and Intervention

-

Beyond drilling, risers can be deployed for workover operations, allowing tools and fluids to reach subsea completions safely.

-

Their temporary and modular nature makes them versatile across different stages of well development.

-

Engineering Example: In deepwater fields offshore Brazil, drilling risers have been used to connect semi-submersibles to subsea wellheads at depths beyond 2,500 m, with riser tensioners maintaining continuous control despite wave heights of up to 10 meters. This demonstrates their indispensable role in bridging subsea infrastructure with surface drilling operations.

Ensuring Reliability in Deepwater Drilling

The drilling riser is the lifeline of deepwater drilling operations. By establishing a secure conduit between subsea wellheads and surface rigs, it enables safe fluid circulation, pressure control, and operational flexibility under extreme offshore conditions. With advanced materials, engineered tensioning systems, and compliance with international standards, Octal Steel supplies drilling risers that meet the demanding requirements of global offshore exploration.

For shallow-water wells, conductor pipes serve as the foundation; for deepwater projects, drilling risers extend the reach and safety of drilling operations. Together, they represent a comprehensive solution for modern offshore oil and gas development.

Social Share