Steel Pipe Fittings

Range of Sizes: 1/2” to 48”

Range of Thickness: SCH 5, SCH 10, Schedule 40, Schedule 80, SCH XS, SCH XXS etc.

Fittings Types: Welded pipe fittings, socket weld pipe fittings, flanged fittings, threaded fittings.

Materials: Carbon steel, Alloy steel, Galvanized and Stainless steel pipe fittings

Standards and Grades: ASTM A234 WPB, WP1, WP5, WP9, WP11, WP22; ASTM A403 304/L, 316/L; ASME B 16.9/11; MSS SP-75;

Pipe fittings are standardized joining and transition components—such as elbows, tees, reducers, caps, unions, and nipples—specified by NPS/OD, schedule (wall), connection type, and material grade to match the connected pipe, maintain pressure integrity, and keep fabrication and inspection acceptance consistent across plumbing, oil & gas, and industrial piping systems. They come in various shapes and sizes, designed to fit specific pipe dimensions and configurations. Common types of steel pipe fittings include:

- Elbows: Used to change the direction of the piping, typically at angles of 90 or 45 degrees.

- Tees: Allow for branching off the main pipeline, creating a T-shaped connection.

- Reducers: Used to connect pipes of different diameters, allowing for a smooth transition between sizes.

- Caps: Used to seal the end of a pipe, preventing flow.

- Flanges: Used to connect pipes, valves, and other equipment, providing a strong and secure joint.

Steel Pipe Fittings Types and Applications

To get a better known to pipe fittings, here we classify them into different types from different sides.

• According different body material for industrial pipelines, there are

Stainless steel pipe fittings

Carbon steel pipe fittings (Black steel pipe fittings)

Alloy steel pipe fittings

• According different coatings, there are

Black painted

PE coated

Cladding stainless steel or alloy steel

Galvanized steel pipe fittings (zinc coated)

• According different industrial purposes, there are

Oil and gas pipelines

Chemical plants

Food industry

Power stations

Fire sprinkler pipe fittings

• According to different connection type, there

Butt weld fittings type

Socket weld fittings type

Threaded type

Flanged type

On the other hand, when we talked about steel elbow, tees, cross or reducer, what are they?

They are the product name that installed exactly at the places in pipelines for playing the different functions and roles.

Pipe Fittings Classification Overview

| Classification basis | Options listed in the article |

|---|---|

| Body material | Stainless steel pipe fittings; Carbon steel pipe fittings (Black steel pipe fittings); Alloy steel pipe fittings |

| Coatings | Black painted; PE coated; Cladding stainless steel or alloy steel; Galvanized steel pipe fittings (zinc coated) |

| Industrial purposes | Oil and gas pipelines; Chemical plants; Food industry; Power stations; Fire sprinkler pipe fittings |

| Connection type | Butt weld fittings type; Socket weld fittings type; Threaded type |

How to describe pipe fitting correctly

Therefore, when you place an order or make an inquiry, the sample description will be like “90 degree stainless steel elbow long radius”, “carbon steel equal tee / reducing tee”, added with specific standards, diameters and wall thickness class, then we will know what exactly you are looking for.

Below let’s see how to range steel fittings from applications.

Application Types

Steel Elbow and Bends: For to change the direction of the pipeline

Steel Pipe Tee: To connect pipes from 3 directions.

Cross: To connect pipes from 4 directions.

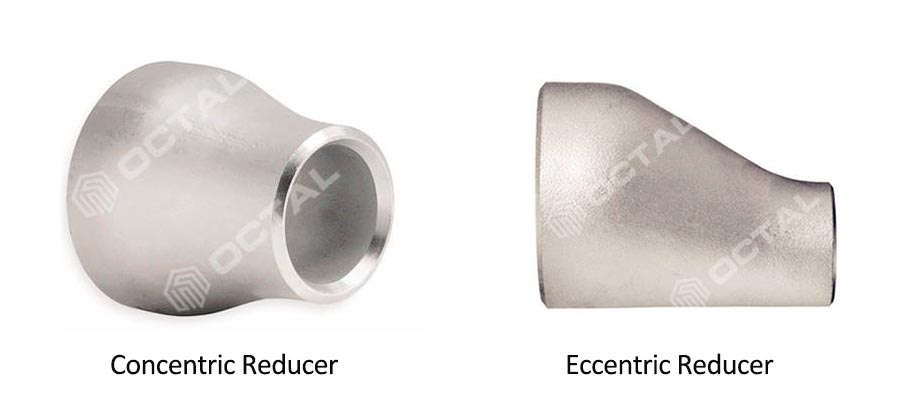

Reducer (Con. Reducer – Ecc. Reducer): Reduce the flow rate of the line pipe system;

Steel Cap: End the pipelines, to seal the pipe.

Nipple

Coupling

Sockolet

Weldolet

Threadolet

Pipe Union

Gasket (Ring)

Line Blanks

Steel Elbow

In the pipe system, steel pipe elbow changes the pipe direction.

45, 90 and 180 degree elbow are the most commonly used. Elbow materials have cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics. The connection ways between elbow and pipe that include flange connection, hot melt connection, fused connection, threaded connection and socket connection.

According to the production process, elbow can be divided into: welding elbow, stamping elbow, pushing elbow, casting and butt welding elbow.

Based on its radius of curvature, elbow can be divided into long radius elbow and short radius elbow

Long Radius Elbow (R=1.5D): Commonly adopted;

Short Radius Elbow (R=1.0D): Usually used in low pressure fluid and size-limited situation. R—elbow diameter, D—radius of curvature.

Steel Pipe Tee

Steel Pipe tee is used for the place where three pipes are assembled. It mainly used to change the direction of fluid in the branch pipe.

Steel Reducer

There are two types concentric reducer and eccentric reducer.

Reducer is one of the chemical pipe fittings that can connect two different diameter pipe. It also divided into concentric and eccentric reducer. Reducer material includes stainless steel reducer, alloy steel reducer, different diameter carbon steel reducer and so on.

Paste-ready (Workfront Scenarios):

-

Shutdown tie-ins on live rack lines: crews have a narrow window to cut-in elbows/tees; consistent center-to-end and bevel geometry helps welders keep stable root condition for RT/UT acceptance.

-

Spool prefabrication for modular skids: fittings are staged by ISO line list; consistent schedule matching reduces “thin-to-thick” surprises that trigger WPS changes mid-run—Octal can batch by line-item to match the fabrication sequence.

-

Pump station / manifold assemblies: eccentric reducers and tees must hold orientation for drain slope and venting; dimensional repeatability reduces field rework around supports and alignment.

Connection types

According to different connection types, steel pipe fitting can be divided into four categories:

Welded pipe fittings

Socket weld pipe fittings

Threaded pipe fittings

Flanged pipe fittings.

Welded steel pipe fitting

Welded steel pipe fittings ranges in butt weld and socket weld.

A welded pipe fitting connected to pipe by welding, it is mainly used for connecting with steel pipe. It is especially suitable for long pipelines, but not convenient for disassembling pipes frequently. It can be soldered or brazed, the latter often used for copper piping. Welded steel pipe fittings include elbow, flange, tee, reducer, head and other types.

Butt weld fittings

Usually with plain ends or beveled ends, and welding directly with pipe ends.

Socket weld pipe fittings

Socket welding is to install the pipe end into the valve body and perform welding. It has shape similar to internal thread connection after forming. Socket welding fittings is generally used for small diameter less than or equal to DN40, which is more economical. Butt welding is generally used for DN40 or more. The connection form of socket welding is mainly used for small diameter valves and pipes, pipe fittings and pipe welding. Because the wall thickness of small diameter pipe is generally thin, easy to edge and ablation, so it gets more difficult for butt welding, so people will go for socket welding.

Threaded pipe fittings

Threaded pipe fittings are commonly used in water and gas pipes. With small diameter, including compressed air pipe and low pressure steam pipe. The common materials of threaded pipe fittings have forged steel, cast steel, cast iron and malleable iron. Threaded pipe fittings mainly include internal pipe, external pipe, live pipe connection, reducer and so on.

Flanged pipe fittings

The flange pipe fitting belong to the welded pipe fitting. Its material have various kinds, such as carbon steel, alloy steel, stainless steel and so on.

Steel Pipe Fittings material standard and grades

As we talked above, based on materials for making the fittings, the are carbon, stainless, or alloy steel, so what are the related standards for these materials?

Material Standard

ASTM A234, for carbon and alloy steel

ASTM A105, for carbon flanges

ASTM A403, for stainless steel pipe fittings

ASME/ANSI B16.9 Factory-Made Wrought Steel Butt-welding Fittings

ASME/ANSI B16.11 Forged Steel Fittings, Socket-Welding and Threaded

MSS SP-75

EN10253-1, DIN2605-1, JIS B2311

GB/T12459, GB/T13401

SH3409, SH3409

HG/T12459, HG/T21631

DL/T695, GD2000

SY/T0518, SY/T0609, SY/T0510

Body material:

For Carbon Steel Pipe Fittings: A234 WPB, A420 WPL6, MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65 and 70.

For Stainless Steel Pipe Fittings: ASTM A403 WP 304, 304L, A403, 316, 316L, 317, 317L, 321, 310 and 904L, etc.

For Alloy Pipe Fittings: A234 WP1, WP5, WP9, WP11, WP22, WP91 etc.

More material for Steel Pipe Fittings are: 16Mn, 16MnR, 12CrMo, 15CrMo, 12Cr1MoV, 0Cr18Ni9, 1Cr18Ni9Ti, 0Cr18Ni12MoTi, 00Cr19Ni10, 00Cr17Ni12Mo2, etc

Pipe Fittings Standards and Grade Summary

| Category | Standards listed | Grades / scope listed in the article |

|---|---|---|

| Carbon & alloy steel fittings | ASTM A234; MSS SP-75 | A234 WPB; A420 WPL6; WPHY 42/46/52/56/60/65/70; WP1/WP5/WP9/WP11/WP22/WP91 |

| Stainless steel pipe fittings | ASTM A403 | WP 304/304L; 316/316L; 317/317L; 321; 310; 904L |

| Butt-weld fitting dimensions | ASME/ANSI B16.9 | Factory-Made Wrought Steel Butt-welding Fittings |

| Socket-weld & threaded fitting dimensions | ASME/ANSI B16.11 | Forged Steel Fittings, Socket-Welding and Threaded |

| Regional / industry standards listed | EN10253-1; DIN2605-1; JIS B2311; GB/T12459; GB/T13401; SH3409; HG/T12459; HG/T21631; DL/T695; GD2000; SY/T0518; SY/T0609; SY/T0510 | As listed in the article |

| Additional materials mentioned | (Materials list) | 16Mn; 16MnR; 12CrMo; 15CrMo; 12Cr1MoV; 0Cr18Ni9; 1Cr18Ni9Ti; 0Cr18Ni12MoTi; 00Cr19Ni10; 00Cr17Ni12Mo2 |

Stainless steel pipe fittings

Stainless steel pipe fittings is usually used for corrosive environments, to protect against pipelines from acid corrosion, for industrial purposes the mainly standard is ASTM A403, this specification includes wrought stainless steel fittings for pressure pipelines. There are several grades under this standard but most used are A403 WP 304, 304L, or 316 and 316L.

Stainless steel pipe fittings selection points (ASTM A403 focus)

Stainless steel pipe fittings are typically specified when internal corrosion risk, cleaning requirements, or chloride-bearing service drives material selection beyond carbon steel. Under ASTM A403, 304/304L and 316/316L remain the most common because they balance availability, weld-ability, and corrosion resistance across general industrial piping.

316/316L stainless steel pipe fittings are often chosen where chlorides or mildly aggressive media increase pitting/crevice corrosion concerns compared with 304/304L. “L” grades are widely used when welding is involved, because lower carbon reduces sensitization risk in the heat-affected zone.

For procurement consistency,Octal stainless steel pipe fittings are commonly controlled by piece-level heat/lot traceability (e.g., 100% marking tied to EN 10204 3.1/3.2 plus a packing-list heat/lot map), grade verification per ITP (PMI 10–100% as specified; L-grades confirmed by heat chemistry such as C ≤ 0.03%), and interface control to the mating pipe. Keeping the fitting’s schedule/class aligned with the connected pipe—and maintaining consistent end prep (e.g., ASME B16.25 bevel 37.5° ± 2.5°, typical root face around 1.6 mm)—helps prevent fit-up mismatch, stabilizes weld profiles, and reduces NDT-driven rework.

pipe fittings supplier scope for stainless steel pipe fittings

A pipe fittings supplier supporting stainless steel pipe fittings typically aligns supply scope across elbows/tees/reducers/caps in the same heat/lot logic, keeps marking and packaging clear for mixed-grade projects, and provides documentation packages (MTC, inspection records) to close approvals without repeated resubmittals—especially when 304L and 316L are both present in the same piping system.

Galvanized steel pipe fittings

First of all, galvanized steel pipe fitting includes malleable cast iron pipe fittings (lower pressure for plumbing) and carbon steel pipe fittings (for higher pressure), these two types has a big differences and for different usage.

On the other hand, there are cold galvanized and hot dipped galvanized, butt weld pipe fittings usually apply hot galvanized.

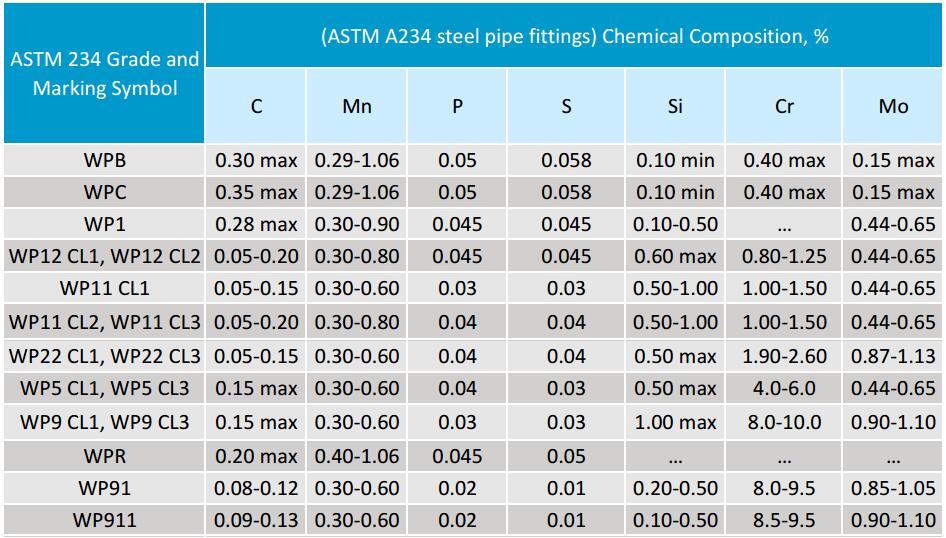

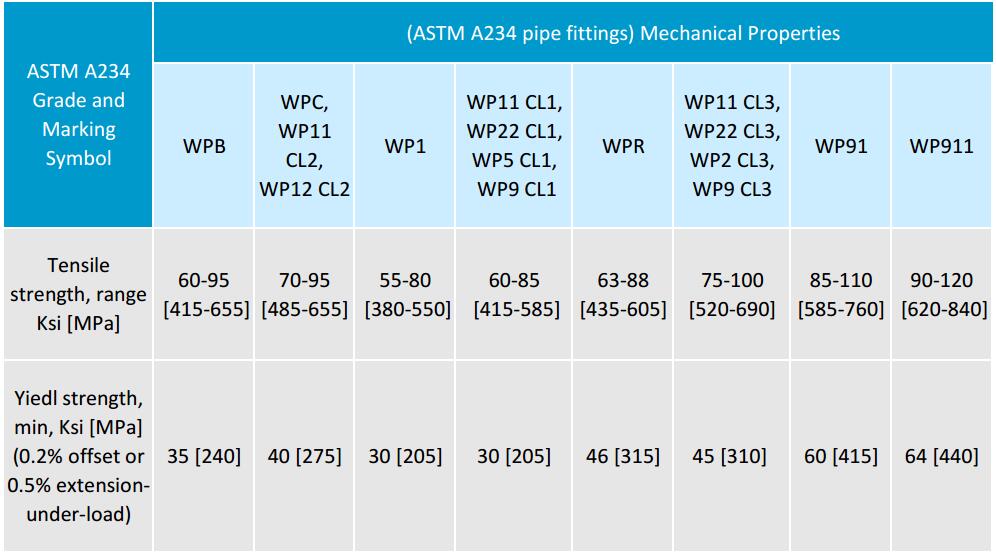

Common standard for carbon and alloy steel pipe fittings: ASTM A234

Chemical composition:

Mechanical properties

Range of Sizes for Steel Pipe Fittings and Accessories

For butt weld fittings sizes available in: 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48”.

For socket weld and threaded pipe fittings sizes in: 1/2”, 1”, 1/2”, 2” and up to 4”.

Thickness for butt weld fittings: SCH 5, SCH 10, SCH 40, SCH STD, SCH 80, SCH XS, SCH 160 and SCH XXS etc.(Schedule 40 steel pipe fittings, and schedule 80 pipe fittings are mostly used.)

Pressure class for socket weld fittings: 3000#, 6000#, 9000#; For threaded pipe fittings pressure ranges in 2000#, 3000# and 6000#

(Flange and gaskets thickness usually described as from 150#, 300#, 600# and up to 2500#. This is different with butt weld fittings but similar to socket weld fittings.)

Pipe Fittings Specification and Size Range Table

| Specification item | Range listed in the article |

|---|---|

| Butt weld fittings size range | 1/2”, 1”, 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 20” to 48” |

| Socket weld & threaded size range | 1/2”, 1”, 1/2”, 2” and up to 4” |

| Butt weld thickness (Schedule) | SCH 5, SCH 10, SCH 40, SCH STD, SCH 80, SCH XS, SCH 160, SCH XXS (Schedule 40 & Schedule 80 mostly used) |

| Socket weld pressure class | 3000#, 6000#, 9000# |

| Threaded pressure range | 2000#, 3000#, 6000# |

| Flange / gasket class note | 150#, 300#, 600# and up to 2500# (as noted on the page) |

Our Supply scope regarding steel pipe fittings

Octal supplies steel pipe accessories and pipe fittings applicable to different industrial areas, Oil & Gas transportation, Chemical Plant, Power Station, Water Treatment, Refining etc

pipe fittings manufacture control points (for approvals and acceptance)

For projects that need stable approvals, pipe fittings manufacture control is commonly verified through material identification, manufacturing route consistency (wrought fittings per the applicable standard), and dimensional checks that keep end prep, wall class, and alignment consistent at site. Typical acceptance packages may include MTC, dimensional inspection, and supplementary test records when required by the project specification.

For mixed connection types (butt weld, socket weld, threaded, flanged), keeping each fitting clearly identified by type, size, schedule/class, and heat number helps reduce installation errors and supports traceability during commissioning and later maintenance.

ASTM Complied

ASTM A234 covers carbon and alloy steel wrought butt-welding pipe fittings (WPB, WPL6, WP1/WP5/WP9/WP11/WP22/WP91).

ASTM A403 covers wrought stainless steel pipe fittings for pressure pipelines (WP304/304L, WP316/316L, 317/317L, 321, 310, 904L).

ASTM A105 is commonly applied where carbon steel forgings are used for flanges and related components.

Dimensional and end-prep control is normally aligned with:

ASME B16.9 (butt-welding fittings) and ASME B16.11 (socket-welding and threaded fittings), with MSS SP-75 used when pipeline-strength fitting scope is specified.

Typical compliance deliverables include:

• Mill Test Certificate (MTC) with heat number traceability, chemistry and mechanical results, and heat treatment record where applicable

• Piece marking and packing list that link each fitting to size, schedule/class, material grade, and heat number

• Dimensional inspection records: NPS/OD, wall (Schedule), center-to-end, angle tolerances (elbows), branch dimensions (tees), concentric/eccentric alignment (reducers), bevel/land and end preparation

• Inspection / test records when required by project scope: VT, MT/PT, UT/RT for welded seam control, plus impact/hardness tests when specified

• Lot segregation for mixed-grade shipments (e.g., 304L and 316L stainless steel pipe fittings) with clear label control through packing and documents

Pipe Fitting NDT Inspection Process — Weld, Dimensions & Corrosion Check

The inspection process ensures that each pipe fitting meets the required specifications before it reaches the job site. Dimensional checks are made to ensure proper NPS/OD and wall thickness alignment with the specified schedule, preventing misfit issues at the weld joint. For reducers and elbows, concentricity and alignment are checked to avoid distortion during welding. The end prep (bevel) is verified to meet ASME B16.25 standards, ensuring a perfect fit for the welding process.

Weld quality is assessed through visual inspection and NDT methods (MT, PT, UT, RT) based on the project’s ITP, verifying that no defects have compromised the pipe’s integrity. Special attention is given to heat-affected zones, as these areas are particularly vulnerable. Finally, before shipment, we ensure the corrosion resistance of the material and check the coating condition to protect the fittings during installation and long-term use. Every inspection is linked back to the heat number for full traceability, and all relevant data is documented in the packing list and MTC.

Octal Pipe Fittings Supplier Support for Approvals and Site Fit-Up

Weld Quality and Dimensional Control

At Octal, as a trusted Pipe Fittings Supplier, we ensure each fitting meets the highest standards. For example, on a project in Buenos Aires, Argentina, our pipe fittings were produced with precise weld bevels at 37.5° ± 2.5°, in line with ASME B16.25. The root face was set to 1.6mm for standard fittings, ensuring stable welding conditions. We conduct strict dimensional checks on OD, wall thickness, and minimum wall thickness to ensure the product meets specifications. Each weld is tested with 100% NDT, including UT and RT, to ensure no defects compromise the integrity of the product.

On-Time Delivery Reliability

Octal understands the importance of on-time delivery. For a recent project in Santiago, Chile, we delivered over 10,000 fittings within 50 days, meeting the project’s tight timeline. This was achieved through precise scheduling and expedited shipping, ensuring the fittings arrived on site without any delays. Our logistics system ensures that all orders are tracked, and customers are kept informed throughout the delivery process.

Long-Term Supply Capacity

As a leading Pipe Fittings Supplier, Octal has the capability to support large-scale, long-term projects. For example, in the Alaska LNG project, we provided a steady supply of 5,000 fittings per month for over a year, ensuring continuous availability of 316L stainless steel fittings. We maintain strict lot segregation and batch control to ensure traceability, and our robust supply chain management guarantees we can meet ongoing demands without any disruptions.

FAQ

Q1: What documents are typically included when ordering ASTM compliant pipe fittings?

A1: A typical package includes MTC with heat number traceability and chemistry/mechanical results, item marking linked to heat/grade, a packing list, dimensional inspection records (NPS/OD, schedule, end prep and key geometry), and any specified NDT or supplementary test reports.

Q2: How do I specify stainless steel pipe fittings for 304L vs 316L procurement?

A2: Specify the ASTM A403 grade (WP304L or WP316L), the applicable ASME dimensional standard (B16.9 or B16.11), size and schedule/class to match the pipe, and the required end prep; 316L is commonly selected when chloride exposure or pitting risk is higher than typical 304L service.

Q3: How do butt weld, socket weld, threaded, and flanged fittings differ in project use?

A3: Butt weld fittings are common for larger sizes and permanent joints; socket weld and threaded fittings are common for smaller bore connections and defined pressure classes; flanged fittings support disassembly and equipment tie-ins, with class rating controlled by the flange standard and project pressure/temperature conditions.

Q4: How does Octal control traceability for mixed-grade shipments of pipe fittings?

A4: Octal uses heat-based traceability with clear marking, lot segregation for different grades and sizes, and packing lists indexed to certificate heat numbers so receiving and QA teams can verify each fitting by type, schedule/class, grade, and heat number during inspection and installation.