stainless steel pipe fittings

ASTM A403 WP: WP304/WP304L/WP316/WP316L

Typical size range: 1/2″ NB–48″ NB; common wall: Sch 10S / 40S / 80S (incl. 2 inch NPS 2)

Fitting types: elbows, tees, caps, reducers, couplings, nipples, bends, olets

Solution annealing (min.): 1900°F [1040°C] (general); 321/347: 1900–2100°F [1040–1150°C]; 321H/347H: 1925–2100°F [1050–1150°C]

Chemistry key point: 316/316L Mo = 2.00–3.00% (grade-defining vs 304/304L)

Tensile (min.): 304/316: YS 30 ksi [205 MPa], TS 75 ksi [515 MPa]; 304L/316L: YS 25 ksi [170 MPa], TS 70 ksi [485 MPa]

Surface limits: fish-scale cracks > 1/64″ (0.4 mm) removed; mechanical defects > 1/16″ (1.6 mm) removed; other discontinuities ≤ 5% of nominal wall

Weld repair not allowed when defect depth > 33 1/3% of nominal wall or affected area > 10% of fitting surface

Stainless steel pipe fittings (butt-weld) for pressure piping are commonly supplied to ASTM A403 as WP-grade austenitic stainless fittings, primarily WP304/WP304L and WP316/WP316L, used for directional change, branching, reduction, and end closure in stainless lines. Acceptance in procurement and site receiving is typically driven by four verifiable items: grade and heat traceability, dimensional conformity to ASME B16.9, heat-treatment condition, and surface condition/repair limits consistent with the A403 program.

This page summarizes the A403 purchasing scope for stainless steel butt weld pipe fittings, including units of description (inch-pound vs SI “M”), referenced standards used in project specifications, fitting types covered, and the technical data that supports release—chemistry by heat, tensile properties and test-report logic, solution annealing requirements, surface discontinuity limits, and weld-repair allowance—so buyers can place an order that is traceable, auditable, and ready for fabrication upon delivery.

Fitting Types Covered (ASTM A403 WP stainless fittings)

ASTM A403 WP stainless steel pipe fittings are typically supplied as factory-made butt-weld fittings to support stainless pressure piping assemblies. For procurement and fabrication control, the fitting type is usually specified together with the applicable dimensional standard (ASME B16.9 or relevant MSS practice), the NPS and schedule, and the ordered grade (WP304/WP304L or WP316/WP316L) so that fit-up, weld prep, and spool weights remain consistent across the package.

Core butt-weld fitting families (most common in stainless spool work)

• Elbows (45° / 90° / 180°)

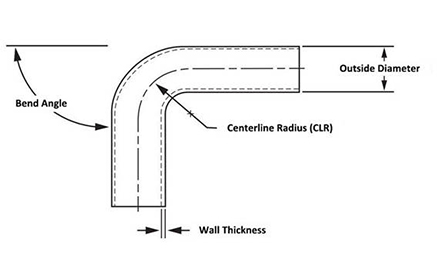

LR vs SR: SR elbow = R 1D (CLR = 1×NPS). LR elbow = R 1.5D (CLR = 1.5×NPS).

45° elbow: Elbow, 45° — LR (R=1.5D) for smoother direction change; SR (R=1D) for compact routing.

90° elbow: Elbow, 90° — LR (R=1.5D) for standard routing / lower loss; SR (R=1D) for tight space.

180° elbow: Elbow, 180° (Return Bend) — U-turn routing / return sections; specify CLR (LR/SR) per layout.

Used for directional change and routing around supports/nozzles. In prefab spools, elbows drive most fit-up hours; consistent end geometry and wall/schedule control reduce mismatch and rework at the weld station.

• Tees (equal / reducing)

Equal tee (Straight tee): Tee, Equal — ASME B16.9 (BW); ASTM A403 WP grade; NPS (run = branch); Sch/STD per line class; SMLS/WLD per spec.

Reducing tee (Reducer tee): Tee, Reducing — ASME B16.9 (BW); ASTM A403 WP grade; NPS (run × run × branch), e.g., 4″ × 4″ × 3″; Sch/STD per line class; SMLS/WLD per spec.

Used to create branch connections in headers and manifolds. Reducing tees are frequently specified where the branch line is smaller than the run; procurement control focuses on correct run/branch sizes and schedule alignment to avoid field reducers being improvised.

• Reducers (concentric / eccentric)

Reducer—CON/ECC — specify NPS (large × small) and Sch; BW: ASME B16.9 (ends plain/beveled); SW insert: ASME B16.11 Type 1/2/3 (typ. NPS ≤ 2).

Used to transition between line sizes. Concentric reducers are common in vertical lines; eccentric reducers are often specified in horizontal lines to manage drainage and pocketing. Correct orientation requirements are usually handled at spool drawing level, but purchasing must still lock the reducer type (ECC/CON) and schedule.

Dimensions and weight details can be referenced in the PDF: Eccentric reducer dimensions and weight.

• Caps (butt-weld caps/socket weld caps)

BW cap: Cap, BW — ASTM A403 WP grade; ASME B16.9; NPS × Sch; end closure / test header / future tie-in.

SW cap: Cap, SW — per line class forged fitting spec; ASME B16.11; NPS × Class (3000/6000/9000); pipe seats into socket shoulder/recess then fillet weld; keep SW caps as separate line items from BW caps to avoid end-type mix.

Used for end closure, test headers, and future tie-in allowances. Cap wall/schedule consistency is important for hydrotest preparation and future cut-and-cap operations.

Connection and specialty forms (project-dependent, but often bundled)

• Olets / branch outlets

Sockolet / Weldolet — branch connection without full-size tee; specify type (Sockolet/Weldolet), run NPS × branch NPS, pressure class (or line class), and end type (SW/BW); ensure reinforcement requirement matches piping class to avoid fit-up/NDE rework.

Used where a branch is taken off a run without a full-size tee, especially on congested racks or retrofit tie-ins. Outlet selection is typically tied to line class and branch reinforcement requirements, so correct type and size pairing prevents rework during fit-up and inspection.

• Bends (induction bends or formed bends, where specified)

Bend vs Elbow (CLR): Elbow = CLR 1D (SR) or 1.5D (LR). Pipe bend = CLR > 2D (e.g., 3D/5D/6D/8D).

Pipe bend: Bend, Pipe — specify CLR (3D/5D/6D/8D or custom) and bend angle (15°/22.5°/30°/45°/60°/90°/180° or custom); NPS × Sch per line class.

Used to reduce weld count in long-radius routing or where smooth flow is required. Purchasing must align bend radius/angle and schedule with the isometric and avoid substituting elbows where a bend is required for geometry.

• Couplings and nipples (when included in the stainless fitting package)

Coupling

Coupling — ASTM A182; Grade F304/F304L or F316/F316L; size up to 20″; type: Socket Weld Coupling / Threaded Coupling / SW×Thread (one end SW, other end threaded); thread form where specified: BTC / EUE / NUE / Premium.

Nipple

Nipple, Pipe — threaded both ends; specify type: Barrel Nipple / Hex Nipple / Close Nipple / Reducer (Unequal) Nipple; size 1/2″–6″; Sch 10/40/80; length = overall (incl. threads) or close; thread standard: BSP/BSPT/NPT/NPSM/Metric; coating where specified: black paint / varnished / galvanized.

Some projects group small-bore connections or threaded/socket items into the same supply scope for convenience. In that case, procurement should explicitly call out the governing dimensional standard (e.g., B16.11 for forged small-bore items) to avoid mixing butt-weld expectations with forged fitting requirements.

What to state in the order (to avoid “functionally similar” substitutions)

For each fitting line item, the purchase description typically includes:

Fitting type (elbow/tee/reducer/cap/olet/bend, etc.)

• Dimensional standard (ASME B16.9 and/or applicable MSS)

• NPS and schedule (including high-usage items such as 2 inch stainless steel pipe fittings (NPS 2) with Sch 10S/40S/80S where applicable)

• Grade (WP304/WP304L or WP316/WP316L) and required documentation/traceability

This approach keeps the delivered stainless fittings consistent with the project line class and reduces downstream issues such as schedule mismatch, incorrect reducer type, or branch outlet substitutions that typically trigger QA holds and fabrication rework.

Specifications & Standard Coverage (ASTM A403 WP)

Standard scope and WP grade logic

ASTM A403 covers wrought austenitic stainless steel piping fittings for pressure piping. Grades are designated with a WP or CR prefix depending on the applicable dimensional/rating standards, and WP grades include classes to indicate seamless vs welded construction and the NDE method/extent used. Cast fittings are outside this scope.

Units of description

ASTM A403 is expressed in inch-pound and SI units. Unless the purchase order specifies the applicable “M” (SI) designation, material is furnished to inch-pound units, and the two systems are treated independently to avoid non-conformance.

Referenced standards

A403 commonly references ASTM A351/A743/A744 (castings, excluded from A403 supply), ASTM A751 (chemistry), ASTM A960/A960M (common requirements), ASTM E112/E165 (testing), ASME B16.9/B16.11 (dimensional/rating), MSS SP-25/SP-43/SP-79/SP-95/SP-97 (marking and fittings practices), and AWS A5.4/A5.9/A5.11/A5.14 (welding consumables).

Product data table

| Item | Stainless Steel Pipe Fittings Supply (Typical) |

|---|---|

| Standard | ASTM A403 (WP / CR prefix) |

| Common grades | WP304 / WP304L / WP316 / WP316L (others available by request) |

| Construction | Seamless or Welded (WP class indicates construction and NDE extent) |

| Size range | 1/2″ NB to 48″ NB |

| Wall / schedule | Schedule 10S / 40S / 80S |

| Common request | 2 inch stainless steel pipe fittings (NPS 2) in Sch 10S/40S/80S |

Application Scenarios

Chloride-bearing water, coastal outdoor racks, and wash-down areas (WP316 / WP316L stainless steel)

When the service includes chloride exposure (cooling water, seawater mist, brine carryover, frequent wash-down), the procurement-driven risk is localized pitting/crevice attack that starts at weld toes, gasket crevices, and low-drain pockets. Selecting WP316/WP316L stainless steel pipe fittings adds molybdenum (controlled on the MTC) and improves resistance in these initiation zones, reducing early leak risk at joints and tight crevices.

• Typical fit: outdoor piping racks near marine air, cooling-water headers, CIP/wash-down utility lines, chemical drain/neutralization where chloride is present.

• Grade selection logic: ⒈ WP316L for welded spools and repeated fabrication (lower carbon improves weld-related sensitization margin). ⒉ WP316 for general stainless fabrication where L-grade is not mandated by the line class.

• How the benefit is made real on site: ⒈Require heat/lot traceability and MTC chemistry by heat for every line item, so the Mo-bearing grade is verifiable at receiving. ⒉ Specify PMI coverage (lot-based or 100% on critical lines) to prevent 304/316 mixing—this is the most common “paper-pass, site-fail” issue in mixed stainless projects. ⒊ Keep pickling/passivation status consistent across lots to avoid uneven surface condition that accelerates local corrosion at weld-adjacent zones.

General process piping, indoor utilities, and food-contact equipment (WP304 / WP304L, SUS 304 stainless steel)

For indoor utilities and general process lines where the dominant requirement is stable corrosion resistance + cleanability (rather than chloride pitting resistance), WP304/WP304L (SUS 304 stainless steel) is typically selected to control cost while maintaining predictable fabrication and hygiene performance.

Typical fit: indoor process lines, compressed air (dry), inert gas, clean water without chloride concerns, food-contact transfer where routine cleaning is the main driver.

Grade selection logic: ⒈ WP304L for welded spools and frequent field tie-ins (controls carbon to improve weld robustness). ⒉ WP304 for standard fabrication where L-grade is not specified by the project.

How the benefit is made real on site:

⒈ Lock the standard + grade + schedule at RFQ/PO level so elbows/tees/reducers do not arrive as “functionally similar but dimensionally mixed” parts.

⒉ Use one heat/lot mapping per shipment so receiving can clear pallets quickly and fabrication can release spools without document hold-ups.

⒊ Keep surface condition consistent (passivated / free of scale) to reduce extra grinding and re-cleaning before welding, which is a common time loss on stainless prefab.

316 vs 304 Stainless Steel for Pipe Fittings

Both 304 and 316 are widely specified for stainless steel pipe fittings, but they are purchased for different risk profiles. The decision is typically driven by whether the service is likely to trigger localized corrosion (pitting/crevice) around joints and low-drain features, or whether the project is dominated by general corrosion resistance, cleanability, and cost stability across a high volume of fittings.

When WP304 / WP304L (SUS 304 stainless steel) is typically specified

WP304/WP304L is commonly selected for indoor utilities and general process services where chloride exposure is controlled and the priority is consistent availability and predictable fabrication.

Typical fit: indoor process piping, dry gas lines, clean water without chloride concern, routine cleaning environments.

Procurement outcome: stable lead time and uniform spool fabrication when grade and schedule are kept consistent across the package.

When WP316 / WP316L is typically specified

WP316/WP316L is commonly selected where chloride-bearing exposure increases the likelihood of early pitting or crevice attack at joints, gasket interfaces, and weld-adjacent zones. In these services, molybdenum-bearing chemistry is treated as a grade-defining acceptance point on the MTC and can be confirmed by PMI when required.

Typical fit: coastal outdoor racks, wash-down utilities, cooling-water services, chloride-containing drains.

Procurement outcome: reduced early leak risk in localized corrosion-prone areas, with acceptance supported by heat-based chemistry traceability.

304L vs 316L for welded spool packages

For prefab spools and field tie-ins, L-grades are frequently specified to support welded fabrication. Where service selection requires 316, choosing 316L keeps the material strategy aligned with welded spool construction and mixed-lot segregation practices.

Is 316 stainless steel magnetic (and is 304 stainless steel magnetic)?

Magnetic response is not a reliable grade identifier for stainless fittings. Austenitic stainless can show low/weak magnetism depending on heat treatment condition and the amount of cold work introduced during forming. For procurement acceptance, grade verification is tied to heat identification, MTC chemistry, and PMI when specified by the project ITP—so material identity is auditable rather than inferred from a magnet test.

System Package

Stainless steel pipe fittings clear faster when the interface set is consistent: pipe + butt-weld fittings + flanges match the same grade family (304/304L or 316/316L), NPS/schedule, and end-prep/dimensional standard. This reduces two common site holds: (1) mixed-grade items inside one kit, and (2) wall/bore mismatches that slow fit-up—especially on repetitive sizes like 2 inch stainless steel pipe fittings (NPS 2). A unified traceability pack (marking → heat → MTC → packing list line-item mapping) helps receiving release the kit as one lot instead of splitting it into partial quarantines.

Quality & Technical Data Pack

Material

A403 WP fittings are made from wrought stainless starting forms such as forgings, bars, plates, and tubular products. Each lot is tied to a furnace/heat identity so chemical and mechanical compliance can be traced to the delivered fittings.

Smelting

A403 programs may use electric-furnace or vacuum melting routes, and may include secondary remelting routes (such as vacuum remelting / ESR-type practice). The practical requirement for procurement is that the melt identity remains coherent across remelted material so the furnace/heat number on the fitting can be reconciled against the material test certificate set.

Forming

Fittings can be produced by methods such as press/hammer forging, extrusion, upsetting, rolling, bending, welding, and machining, or combinations of these. The key acceptance outcome is that forming does not introduce harmful defects and that the finished geometry remains within the applicable dimensional standard.

Heat treatment

A403 WP stainless fittings are commonly supplied in the specified heat-treated condition. Where welding is part of the manufacturing route, it is completed prior to final heat treatment. When fittings are machined from solution-annealed starting stock under controlled conditions, additional re-annealing may not be required depending on the product route and grade requirements.

For H-grade materials, solution annealing requires a dedicated solution heat treatment cycle. Fittings are supplied in the heat-treated condition, and any manufacturing welding is completed prior to final heat treatment. Where fittings are produced by direct machining from solution-annealed forgings or bars, re-annealing is not required for that route.

Solution Annealing / Heat Treatment (ASTM A403)

| Grade | Solution Annealing Temperature, °F [°C], min. Unless Range Specified |

|---|---|

| All except those listed below | 1900 [1040] |

| 348H | 1925 [1050] |

| S31254 | 2100 [1150] |

| S33228 | 2050 [1120] |

| S34565 | 2050–2140 [1120–1170] |

| 321, 347 | 1900–2100 [1040–1150] |

| 321H, 347H | 1925–2100 [1050–1150] |

Chemical composition

Chemical composition is verified by heat and released only when it meets the ordered grade requirements. The MTC reports the chemistry results against the same heat identity marked on the fittings, enabling receiving inspection to confirm grade compliance and maintain heat/lot segregation across mixed packages. Where the project ITP requires positive grade segregation, PMI is applied at the defined scope to prevent 304/316 mix-ups during receiving and fabrication.

| Grade | Composition, % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade WP | Grade CR | UNS Designation | C | Mn | P | S | Si | Ni | Cr | Mo | Ti |

| WP304 | CR304 | S30400 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 8.0–11.0 | 18.0–20.0 | … | … |

| WP304L | CR304L | S30403 | 0.030E | 2.00 | 0.045 | 0.030 | 1.00 | 8.0–12.0 | 18.0–20.0 | … | … |

| WP310S | CR310S | S31008 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 19.0–22.0 | 24.0–26.0 | … | … |

| WP316 | CR316 | S31600 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0–14.0 | 16.0–18.0 | 2.00–3.00 | … |

| WP316L | CR316L | S31603 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0–14.0 | 16.0–18.0 | 2.00–3.00 | … |

| WP321 | CR321 | S32100 | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 9.0–12.0 | 17.0–19.0 | … | G |

Tensile properties (A403 WP/CR grades)

| All WP and CR Grades | Yield Strength, min ksi [MPa] |

Tensile Strength, min ksi [MPa] |

|---|---|---|

| 304, 304H, 309, 310, 316, 316LN, 316H, 317, 317L, 321, 321H, 347, 347H, 348, 348H, S31725 | 30 [205] | 75 [515] |

| 304L, 316L | 25 [170] | 70 [485] |

| 304N, 316N, S31726 | 35 [240] | 80 [550] |

| XM-19 | 55 [380] | 100 [690] |

| S31254 | 44 [300] | 94 [650] to 119 [820] |

| S33228 | 27 [185] | 73 [500] |

| S34565 | 60 [415] | 115 [795] |

The tensile properties of fitting materials must meet the tensile requirements. Testing and reporting are carried out in accordance with ASTM A370 methods and definitions. Tensile specimens may be cut longitudinally or transversely; where elongation requirements are defined for both directions, the applicable requirement is evaluated in the corresponding specimen direction.

Tensile test report logic

A403 programs recognize two compliant report paths:

• Starting material tensile reports can support compliance when the heat treatment condition matches the fitting material.

• When starting material was not tested, or when the heat treatment condition differs, a tensile test is performed on material representing the finished fittings under the same heat treatment condition, tied to the furnace steel identity.

starting material vs finished fittings

When tensile test reports are based on starting materials, the reports remain valid only when the heat treatment condition of the starting material is the same as the heat treatment condition of the fittings. If the starting material was not tested, or if the heat treatment condition differs, the fitting manufacturer performs at least one tensile test for each furnace steel on material representing a fitting, and the test heat treatment condition matches that of the representative fittings.

Surface Treatment

Fittings supplied to this standard are visually examined and typical surface discontinuities are measured for depth. Surface “fish-scale” cracks deeper than 1/64 in (0.4 mm) are removed. Mechanical defects deeper than 1/16 in (1.6 mm) are removed. Except for these two items, surface discontinuities are not deeper than 5% of the specified nominal wall thickness, and the finished surface is maintained in a sound machinable condition.

Surface dressing, local repair, and weld repair allowance

Surface dressing is used to remove localized imperfections within defined limits, followed by re-inspection to confirm an acceptable surface condition for welding and service.

Weld repair allowance is controlled by strict limits; when defect depth or affected area exceeds the allowable thresholds, weld repair is not applied and the fitting does not pass release. This protects the buyer from accepting fittings that may later be rejected by site QA or create uncertainty in service.

On-Site Advantages (fit-up, weld-ability, acceptance points)

Geometry that reduces weld time (fit-up controls that survive prefab reality)

For stainless spool work, “geometry” is not a marketing word—it is the difference between a spool that welds the first time and a spool that burns hours in re-fit and re-bevel. Procurement achieves this on site by locking three fit-up items into the supply package and verifying them at receiving:

• End preparation consistency: Butt-weld ends are supplied with a consistent bevel profile per the applicable end-prep practice, so welders do not have to re-cut lands or re-angle bevels across the same spool kit. This is especially visible on high-turn items such as 2 inch stainless steel pipe fittings (NPS 2) where the number of welds magnifies small inconsistencies.

• Schedule alignment across the lot: The delivered elbows/tees/reducers match the ordered schedule (Sch 10S/40S/80S), preventing wall mismatch at the joint that forces extra weld metal, grinding, and additional NDE risk.

• Roundness and end-face stability: End conditions are kept stable enough that standard fit-up tools and tack sequences work as expected, reducing time lost to forcing alignment or correcting mismatch before welding.

The practical result is predictable root opening, stable tack-up, and fewer “fit-up holds” triggered by the inspector during spool fabrication.

Surface integrity with measurable thresholds (what the inspector checks before you can weld)

On stainless fittings, surface condition affects both weld quality and acceptance speed. A403 programs manage this through measurable discontinuity limits and re-inspection after dressing, which makes the delivered surface predictable for fabrication:

• Defined removal thresholds: Surface “fish-scale” cracks deeper than 1/64 in (0.4 mm) are removed; mechanical defects deeper than 1/16 in (1.6 mm) are removed; other discontinuities are controlled to ≤ 5% of nominal wall thickness. These numbers allow receiving inspection and shop QA to make a fast accept/reject decision without subjective debate.

• Re-inspection after dressing: When local grinding is performed, the area is rechecked so the fitting surface remains suitable for welding and does not hide undercut-like defects that later appear as PT/VT issues.

• Consistent surface condition across the package: “Free of scale / passivated” supply reduces extra cleaning and rework before welding, which is a common hidden cost in stainless prefab—especially when multiple crews work in parallel and surface condition variability causes uneven weld outcomes.

This approach reduces the probability of discovering unacceptable surface conditions only after fit-up has started and the spool is already consuming fabrication hours.

Repair rules that prevent hidden risk from shipping (release gates that reduce NCR cost)

he highest-cost failures in stainless projects are not found in the supplier yard—they are found after the jobsite has committed labor. A403 weld-repair allowance is therefore treated as a procurement-side release gate to avoid shipping fittings that will later trigger NCRs:

⒜ Hard limits on weld repair: Weld repair is not permitted when defect depth exceeds 33 1/3% of nominal wall thickness or when affected area exceeds 10% of fitting surface area. Fittings outside these limits are not “repaired and blended”; they are not released.

⒝ Controlled defect removal: Unacceptable areas are removed by mechanical methods or approved thermal cutting/gouging, then cleaned and re-inspected to confirm the base material is sound.

⒞ Impact on project acceptance: By controlling repair eligibility before shipment, the buyer avoids late-stage rejection at receiving or during spool inspection, which otherwise causes fabrication stop-starts, reordering, and schedule disruption.

For procurement, these three controls—fit-up geometry, surface thresholds, and repair eligibility—translate directly into fewer site holds, fewer rework cycles, and smoother acceptance against the project ITP.

Cooperation Experience (delivery control, batch isolation, and receiving speed)

Ordering Notes (PO fields that prevent rework)

Standard: ASTM A403 (state SI requirement explicitly if the project requires SI delivery designation)

Grade: WP304/WP304L or WP316/WP316L

Construction / class: seamless or welded; NDE class/extent aligned to project ITP

Dimensional standard: ASME B16.9 (butt weld) and any applicable MSS requirement by fitting typ

Size & schedule: include critical repeats such as 2 inch stainless steel pipe fittings with Sch 10S/40S/80S

Surface condition: passivated / free of scale; specify any additional finish requirement

Repair acceptance: weld repair allowance governed by the A403 program requirements

Documentation pack: MTC by heat, test report set, and packing list line-item mapping by heat/lot

Octal Pipe execution advantages

Octal Pipe supplies stainless steel pipe fittings as a release-controlled package designed for fast receiving clearance and predictable site fabrication:

• Grade-mix control for 304/316: Orders are organized by grade and heat/lot so mixed pallets do not turn into mixed spools. Receiving teams can reconcile markings against the packing list without opening and re-sorting every carton.

• Release gates aligned to acceptance: Surface condition and repair allowance are treated as shipment release criteria. This reduces the chance that “acceptable in the warehouse” becomes “rejected at site,” which is where NCR cost and schedule loss typically occur.

• Documents tied to the parts that ship: MTCs, tensile report logic, and inspection records are assembled to match furnace/heat identity and packing list line items. Inspectors can verify compliance by heat/lot rather than chasing ambiguous PDFs.

• Faster flow on repetitive sizes: High-consumption items like 2 inch fittings ship with stable labeling and line-item mapping so site QA can clear them quickly and keep fabrication moving.

FAQ

Q1: What are stainless steel butt weld pipe fittings?

A1: Stainless steel butt weld pipe fittings are factory-made components—such as elbows, tees, reducers, and caps—that are welded directly to stainless pipe ends for pressure piping and process lines, commonly supplied as ASTM A403 WP grades.

Q2: What does WP mean in ASTM A403 stainless fittings?

A2: WP identifies wrought stainless fitting grades used for pressure piping supply programs; the WP class can indicate the construction route (seamless or welded) and the NDE method/extent associated with the fitting class.

Q3: 304 vs 316 stainless steel — what is the difference for fittings?

A3: 316 includes molybdenum and is commonly selected where chlorides increase pitting risk; 304 is widely used for general service environments where broad corrosion resistance and cost control are priorities.

Q4: Is 316 stainless steel magnetic (and is 304 stainless steel magnetic)?

A4: In the annealed condition, 304 and 316 austenitic stainless are generally non-magnetic or weakly magnetic, but cold work and certain fabrication conditions can increase magnetic response; grade confirmation is tied to heat identity, MTC chemistry, and PMI where required.