Vacuum Insulated Tubing

Outer × Inner Pipe: 2-⅞” × 1.9″ to 7″ × 5-½”

Outer Pipe OD × WT: 73.02 × 5.51 mm to 177.8 × 9.19 mm

Inner Pipe OD × WT: 48.26 × 3.68 mm to 139.7 × 7.72 mm

Weight: 13.5 kg/m to 65 kg/m

Insulation Grade: B, C, D, E

Thermal Conductivity (λ): 0.06 – 0.002 W/m·°C

Thread Type: USS, BTC, or custom options

Vacuum Insulated Tubing (VIT) – OCTAL Technical Overview

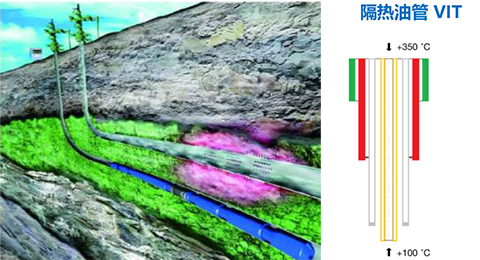

Thermal-Control Tubing for Steam Injection, Heavy Oil Production, Deep water Wells & Geothermal Systems Maintaining temperature inside the well-bore is essential for a wide range of modern oil & gas and geothermal operations. Heat loss not only reduces production efficiency but also increases risks such as wax deposition, formation instability, and thermal fatigue of casing and cement. OCTAL Vacuum Insulated Tubing (VIT) is engineered to address these challenges by providing a highly efficient thermal barrier along the production or injection string.

Product Introduction

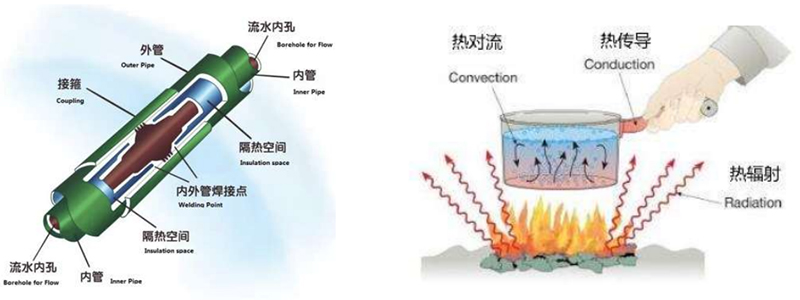

OCTAL VIT consists of an inner flow pipe and an outer protective pipe assembled into a concentric dual-tube system. The annular space between them is vacuum-sealed and integrated with thermal insulation layers. This configuration minimizes heat transfer through conduction, convection, and radiation, allowing high-temperature media—such as steam, thermal fluids, or geothermal water—to maintain stable temperatures throughout their travel in the well. The product is designed to operate under continuous high-temperature exposure and repeated thermal cycling, making it suitable for challenging well environments.

Functional Benefits for Engineering and Procurement

Maintaining Heavy Oil Mobility: When heavy crude cools in the well bore, viscosity increases sharply, limiting flow and decreasing daily production. VIT helps preserve the temperature profile along the tubing, enabling higher production rates without relying on auxiliary heating systems.

Enhancing Steam Delivery Efficiency: For SAGD, CSS, and other steam-based enhanced recovery processes, the quality of steam delivered into the reservoir directly impacts overall recovery. VIT reduces heat loss to the casing and cement sheath, improving the thermal efficiency of steam injection and reducing thermal stress on surrounding well components.

Lowering Hydrate and Pressure Risks in Deep water Wells: During shut-ins, deep water wells may form methane hydrate plugs as the fluids cool. VIT delays hydrate formation and reduces the likelihood of unintended heating of hydrate-bearing formations, which can destabilize the well. It also helps mitigate annulus pressure buildup.

Protecting Permafrost Zones: In cold regions, heat transfer from the tubing string can cause thawing of permafrost, leading to ground settlement and structural concerns. VIT acts as a thermal shield, preserving the temperature balance around the wellhead area.

Improving Geothermal Production Efficiency: In geothermal systems, temperature is directly tied to power generation efficiency. VIT minimizes thermal losses in the upper well section, helping maintain stable and high-temperature flow to surface equipment.

Engineering Design Characteristics

Key features of OCTAL’s VIT design include:

Dual-pipe construction: inner pipe for fluid transport; outer pipe for mechanical protection.

Multi-layer insulation system: reflective foil, insulation materials, and a high-vacuum environment working together.

Pre-stressed inner tube: improves welding integrity and reduces thermal deformation.

Controlled vacuum system: getter materials maintain long-term vacuum performance.

Full-process NDT: applied to base tubes, welds, vacuum ports, and final thermal conductivity tests.

The overall design ensures reliability under high temperature, high pressure, and multi-cycle thermal loading conditions.

OCTAL VIT Technical Specifications

Main Dimensional Range

| Model | Outer × Inner Pipe (in.) | Outer Pipe OD × WT (mm) | Inner Pipe OD × WT (mm) | ID / Annulus (mm) | Thread Type | Weight (Kg/m) | Insulation Grade |

|---|---|---|---|---|---|---|---|

| 73 × 40 | 2-⅞” × 1.9″ | 73.02 × 5.51 | 48.26 × 3.68 | 40.9 / 6.87 | USS 88.9 | 13.5 | B |

| 89 × 50 | 3-½” × 2-⅜” | 88.9 × 6.45 | 60.32 × 4.83 | 50.66 / 7.84 | USS 108 | 20.5 | C |

| 114 × 76 | 4-½” × 3-½” | 114.3 × 6.88 | 88.9 × 6.45 | 76 / 5.82 | BTC 132.1 | 32 | D |

Thermal Conductivity Grades

| Grade | λ (W/m·°C) | Btu/(ft·h·°F) |

|---|---|---|

| B | 0.06 – 0.04 | 0.0347 – 0.0231 |

| C | 0.04 – 0.02 | 0.0231 – 0.0116 |

| D | 0.02 – 0.006 | 0.0116 – 0.0035 |

| E | 0.006 – 0.002 | 0.0035 – 0.0012 |

Manufacturing Workflow

OCTAL follows a controlled manufacturing workflow to ensure stable insulation performance: Seamless pipe rolling → heat treatment → NDT, Insulation wrapping and curing of inner pipe, Concentric assembly and controlled stretching, Precision double-pipe welding, Vacuum extraction and getter activation, Weld inspection and vacuum port verification, Thermal conductivity testing, threading, and packaging.

Supply Range & Optional Configurations

Steel Grades: N80, L80-1, L80-1Cr, L80-3Cr, L80-9Cr, Q125, S135

Connections: API BTC, premium gas-tight threads (BL-2T, integral)

Lengths: R2 / R3; short sections available

Customization: non-standard sizes, special insulation requirements, premium connections

OCTAL VIT is deployed in multiple thermal recovery and geothermal projects with proven in-field performance.