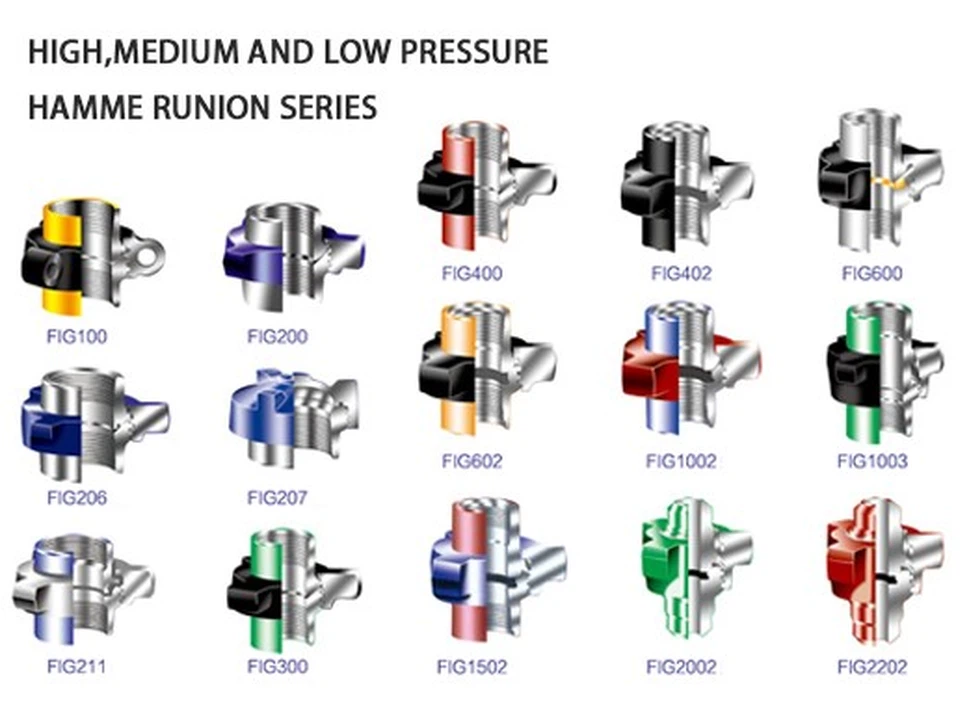

Hammer Unions

-

Size & Pressure Range

-

Sizes: 1″ to 4″

-

Pressure: 2,000 to 20,000 psi

-

Compatibility: FMC / WECO style figures

-

-

Versatile Applications

-

Ideal for frac spreads, choke manifolds, well test lines

-

Suitable for oil & gas, chemical, water treatment, and power generation

-

-

Seamless Integration

-

Matching Components: pup joints, tees, elbows, manifold spools

-

In high-pressure oilfield operations, even minor component issues—such as incorrect figure numbers, pressure ratings, or thread types—can lead to costly delays. These problems often arise from hammer unions, which are critical to maintaining pressure integrity. Octal Pipe offers a full range of high-pressure hammer unions designed for applications like frac spreads, choke manifolds, and well test lines. Our portfolio spans 1″ to 4″ sizes, and 2,000 to 20,000 psi pressure ratings, all compatible with mainstream FMC/WECO style dimensions. This ensures easy integration into existing systems without the need for redesigns or rework. Additionally, we supply a complete set of matching iron, including pup joints, tees, elbows, crosses, telescopic and pneumatic unions, and manifold spools. This allows for streamlined procurement and reduces the risk of mismatched components.

For operations involving H₂S or CO₂, we offer NACE MR0175 compliant hammer unions, ensuring that the material and seals meet stringent sour service requirements. Octal’s hammer unions are built to withstand tough conditions, providing reliable performance under pressure. Whether you’re working with high-frequency cycling or abrasive fluids, our products ensure consistent sealing and durability, meeting the demands of both standard and sour service applications. By sourcing from Octal, you receive not only individual parts but a fully coordinated solution, designed to reduce installation time and ensure compliance with relevant industry standards.

Technical Specifications

For sour service conditions, including H₂S and CO₂, Octal can supply hammer unions with NACE MR0175 / ISO 15156 compliant materials and seals, meeting both mechanical and environmental standards.

| Item | Range and Description |

|---|---|

| Nominal Sizes | 1″, 1½”, 2″, 2½”, 3″, 4″ |

| Working Pressure | 2,000 / 3,000 / 5,000 / 10,000 / 15,000 / 20,000 psi |

| Figure Numbers | Fig 100 / 200 / 206 / 602 / 1002 / 1003 / 1502 / 2002 / 2202 |

| Service Types | Standard service; sour service (H₂S) with NACE MR0175 / ISO 15156 materials |

| Temperature Range | -29 °C to +121 °C (PU class); low-temperature options available |

| Materials | Alloy steel, stainless steel, nylon unions for low-pressure corrosive lines |

| Design Basis | Based on API 16C high-pressure iron and API 6A standards |

| End Connections | F×F, F×M, M×M, butt-weld ends, LP/tubing threads, NPT, flanged ends, hose union ends |

| Figure Number |

CWP | Nominal Size(Inches) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | Service | 1″ | 1 1/4″ | 1 1/2″ | 2″ | 2 1/2″ | 3″ | 4″ | 5″ | 6″ | 8″ | 10″ | 12″ | 14″ | 16″ | |

| CWP | TEST | |||||||||||||||

| FIG100 | 1000 | 1500 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| FIG200 | 2000 | 3000 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| FIG206 | 2000 | 3000 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| FIG207 | 2000 | 3000 | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| FIG211 | 2000 | 3000 | ✓ | ✓ | ||||||||||||

| FIG300 | 2000 | 3000 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| FIG400 | 4000 | 6000 | ✓ | ✓ | ✓ | |||||||||||

| FIG600 | 6000 | 9000 | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| FIG602 | 6000 | 9000 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| FIG1002 | 10000 | 15000 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| FIG1003 | 10000 | 15000 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| FIG1502 | 15000 | 22500 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| FIG2002 | 20000 | 30000 | ✓ | ✓ | ✓ | |||||||||||

| FIG2202 | 20000 | 30000 | ✓ | ✓ | ✓ | |||||||||||

Why Choose Octal Hammer Unions?

Octal’s high-pressure hammer unions are specifically designed to meet the demanding conditions of oilfield services. With sizes ranging from 1″ to 4″ and pressure ratings from 2,000 to 20,000 psi, our hammer unions are compatible with popular FMC / WECO style figures and pressure classes. This ensures that our products fit seamlessly into existing iron systems, reducing downtime and the need for system redesigns. We offer a variety of hammer unions and matching components, including pup joints, elbows, tees, crosses, valves, and manifold spools, for both standard and sour service applications (NACE MR0175 compliant). Our unions are engineered to handle high-pressure, high-pulsation environments, making them ideal for demanding oilfield conditions.

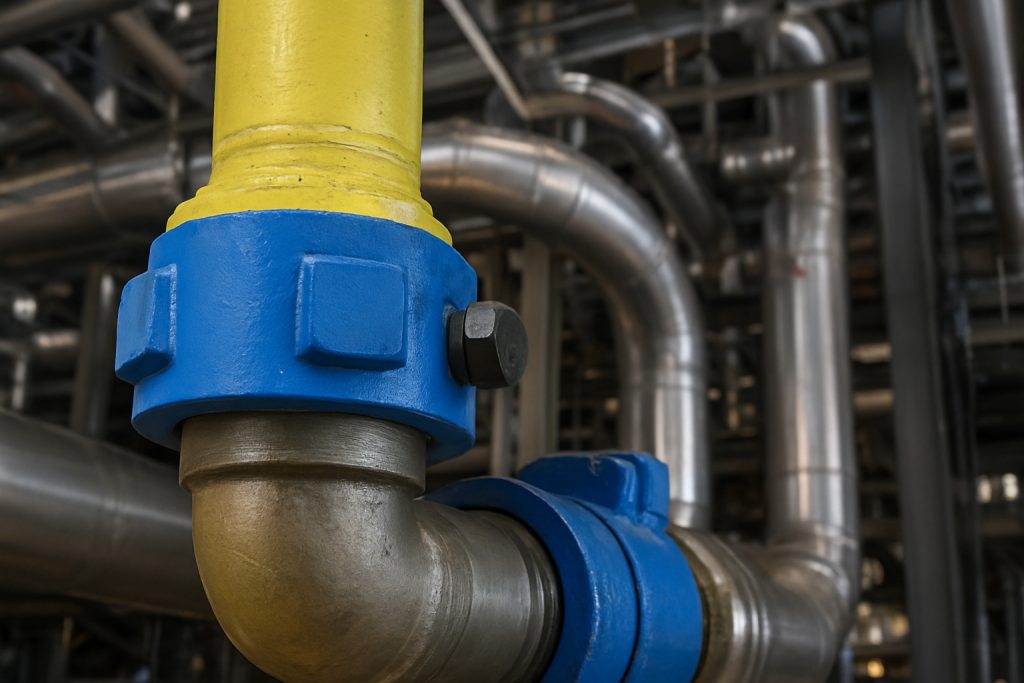

How Our Hammer Unions Can Be Applied Across Diverse Industrial Projects

Octal hammer unions are versatile components that ensure secure, leak-proof connections in critical, high-pressure systems across a wide range of industrial applications. Below are a few scenarios where our hammer unions excel, and how they ensure seamless operations in even the most demanding environments:

Oil & Gas Drilling and Production:Hammer unions are widely used in high-pressure frac operations and offshore oil rigs, where equipment reliability is paramount. These unions play a crucial role in maintaining the integrity of surface drilling lines, ensuring stable connections between pressure equipment like pumps, valves, and risers. Octal’s hammer unions handle extreme pressures, from high-frequency cycling to constant fluid flow, making them an ideal choice for operations in the oil and gas industry.

Operational Use Scenario: Connecting blowout prev-enters (BOP) and mud lines in deep-water rigs or connecting frac pumps to the surface frac iron in hydraulic fracturing operations.

Challenges Solved: Withstanding the extreme conditions found in deep-water exploration and fracking sites. Hammer unions provide quick and secure connections under fluctuating high pressures (up to 20,000 psi) and heavy fluid loads (including sand-laden slurry).

Water Treatment and Wastewater Systems:Water treatment plants and wastewater processing stations often operate under fluctuating pressures and stringent regulations. Hammer unions in these systems provide reliable sealing solutions, especially in high-pressure injection and filtration lines. They ensure that pressurized water or waste does not escape, maintaining system efficiency and protecting both the workers and the environment.

Operational Use Scenario: Connecting high-pressure pumps to filtration and treatment units, isolating and maintaining pipelines, and managing pressure release systems in large-scale water treatment plants.

Challenges Solved: Ensuring that pressure lines in wastewater treatment facilities remain secure under pressures of 2,000-15,000 psi. Our hammer unions are designed to endure high-frequency cycles while maintaining consistent sealing performance.

Power Generation – Steam and Gas Turbine Systems:Hammer unions are also crucial in power generation systems, particularly in steam and gas turbine plants where temperature and pressure control is critical. These unions can be used to maintain connections in high-pressure steam and cooling lines, ensuring that pressure fluctuations or vibrations don’t affect plant efficiency.

Operational Use Scenario: Connecting various pressure components in steam and gas systems, particularly in systems where expansion and contraction of materials are frequent due to thermal cycling.

Challenges Solved: Avoiding leaks and wear in high-temperature, high-pressure systems. Octal’s hammer unions maintain a high standard of sealing, even in the face of extreme thermal cycling and mechanical stresses.

Construction and Heavy Equipment:In construction and heavy equipment applications, hammer unions are often used in large hydraulic systems, such as concrete pumping or in construction projects that require high-pressure water or slurry transport. Their ability to handle fluctuating pressures and provide rapid, tool-free connections makes them a top choice for these industries.

Operational Use Scenario: Connecting hydraulic pumps and valves in concrete pumping operations or during the delivery of high-pressure water and slurry systems at construction sites.

Challenges Solved: Construction environments are fast-paced, and unions must be reliable and easy to install or break down. Our hammer unions are designed for quick assembly and disassembly, allowing crews to work efficiently without downtime.

Field Experience – Benefits of Using Octal Hammer Unions

Field operators rely on Octal hammer unions for their fast, reliable, and simple connection solutions. The advantages of using our unions include:

Ease of Assembly and Disassembly: Hammer unions are easy to make up and break out, requiring only a sledgehammer to tighten or loosen the connection. This speeds up the setup and breakdown process, especially in tight, high-pressure environments.

High Pressure and Durability: Octal hammer unions can withstand pressures of up to 20,000 psi and are designed to handle strong pulsations and high-frequency cycling. Their durability ensures they perform consistently throughout the life of the iron.

Compatibility with Different Media: From clean water and oil to cement slurry, acid, and sour produced fluids, Octal’s unions are built with the right materials and elastomers (e.g., NBR, HNBR, FKM) to suit a wide range of media and temperature requirements. Sour service unions are NACE MR0175 compliant, ensuring superior resistance to cracking and leakage.

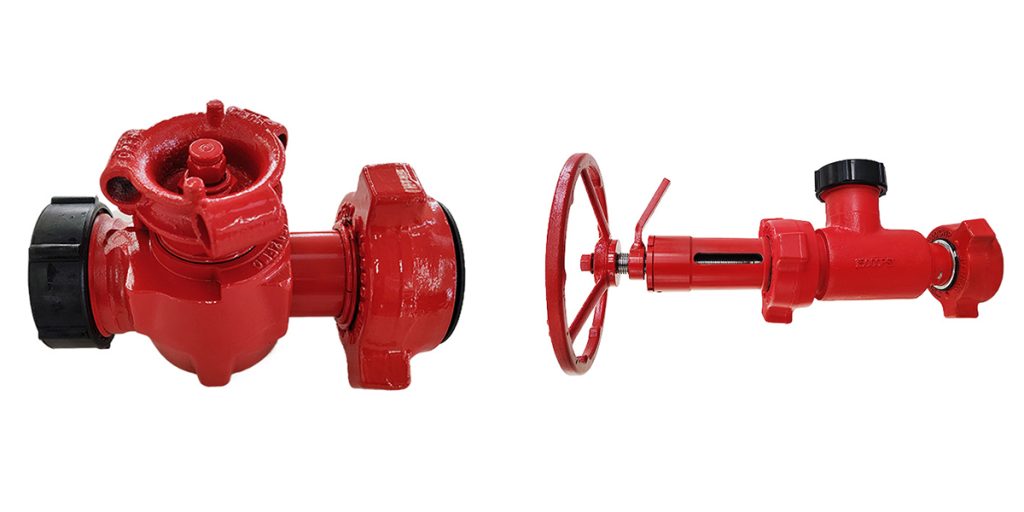

Complete System Solution

Octal offers more than just hammer unions; we provide a full high-pressure iron system. For frac and well test systems, we supply: Union pup joints, Integral tees and crosses, Long-radius and 90° elbows, Plug valves and choke valves with union ends.

This complete solution ensures that all components are designed to work together seamlessly, allowing for efficient installation and operation across the entire system. By standardizing the connection types, sizes, and pressure ratings across all components, we simplify procurement and system integration

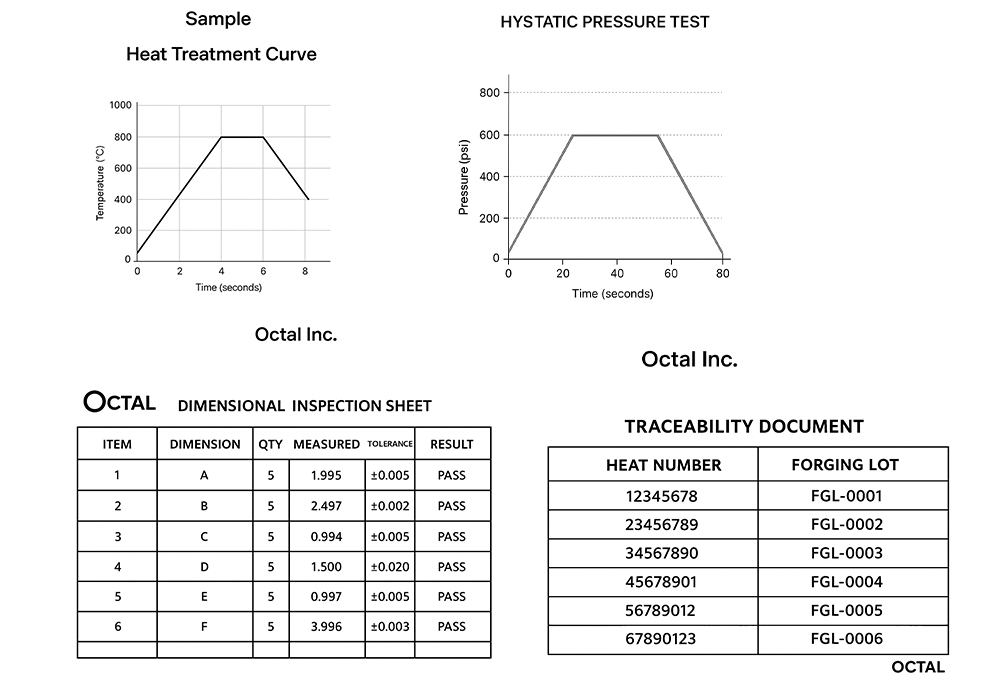

Quality and Documentation – Built to Last and Pass Inspection

Octal’s hammer unions are designed not only to deliver high performance but also to meet strict global requirements for quality control, documentation, and traceability.

For procurement teams, our products help shorten approval cycles, reduce inspection delays, and ensure full transparency throughout the supply chain.

Full Material Traceability:Octal ensures 100% material traceability from raw steel forging to finished hammer unions.

Every heat number, forging lot, and machining batch is documented and can be verified during customer audits.

Traceability Includes: Heat number tracking, Forging lot identification, Machining and assembly batch records, Material certificates stored for every order

This system helps buyers easily meet internal QA requirements and third-party inspection procedures.

Precision CNC Manufacturing:All sealing surfaces, ACME threads, and union seat geometries are fully CNC-machined to ensure dimensional accuracy and interchangeability.

Benefits for Buyers: Guaranteed compatibility with FMC / WECO style hammer unions, Uniform sealing performance across all batches, Reduced field installation issues, Lower maintenance and replacement frequency, CNC precision minimizes deviation and ensures long-term reliability under high pressure and vibration.

Rigorous Hydro-static & Sealing Tests:Each production batch undergoes pressure testing up to 1.5 × Working Pressure (WP).

Testing Includes: Hydro-static test,Sealing test,Visual & dimensional inspection,Batch-specific test reports

Comprehensive Documentation Package:To support compliance and streamline inspection processes, Octal provides a complete certification file for every product.

Documentation Provided: EN 10204 3.1 / 3.2 Material Certificate,Hydro-static Pressure Test Report,Seal Test Report, Heat Treatment Chart,Dimensional Inspection Report,Traceability List (Heat numbers, forging lots, machining batches). This ensures smooth approval with EPC contractors, drilling operators, and energy companies.

Technical & Documentation Summary Table

| Category | Details |

|---|---|

| Material Traceability | Full traceability for all materials, heat numbers, forging lots, machining batches |

| Manufacturing Accuracy | CNC machining; FMC/WECO compatibility |

| Pressure Testing | Hydro-static & seal test up to 1.5 × WP |

| Documentation Provided | EN10204 3.1/3.2, pressure test report, heat treatment chart, dimensional report |

| Compliance Level | Meets global QC and traceability standards |

Working with Octal – Streamlining Your Project

Choosing Octal as your supplier for hammer unions and related iron systems brings several advantages:

Specification Alignment: We work closely with you to map your specifications to our product catalog, ensuring that your requirements are met with precision.

Single Source Responsibility: With all parts coming from a single source, you simplify procurement, scheduling, and technical communication.

Efficient On-Site Installation: Unified specifications make installation faster and more predictable, reducing the need for custom adaptor or field modifications.

Seamless Acceptance and Handover: Our consistent documentation and labeling ensure smooth inspections and faster project handovers.

Social Share