Boiler Pipe Material Specification and Application

Boiler steel pipe refers to specialized seamless steel tubes designed for use in high-temperature and high-pressure environments, particularly within power generation and petrochemical facilities. According to manufacturing practice, boiler pipes are divided into medium-pressure boiler pipes and high-pressure boiler pipes, both of which are almost exclusively produced using seamless processes due to the stringent requirements for strength, reliability, and resistance to failure. Welded steel pipes are generally not applicable for such critical services, as seam integrity can be a limiting factor under cyclic thermal stress.

These pipes serve as essential components in heat exchanger tubing, tube bundles, economizers, superheaters, and high-pressure boilers, where stable mechanical properties and resistance to oxidation at elevated temperatures are indispensable. Their design and production must strictly conform to standards such as ASTM, ASME, DIN, and EN specifications to ensure performance in demanding operating conditions. By combining metallurgical quality, dimensional accuracy, and pressure tolerance, boiler steel pipes play a pivotal role in the safety and efficiency of thermal and chemical process industries.

It has been widely used at heat exchanger pipe and tubing services, tube exchanger bundle, high pressure boiler, economizer, super heater, petrochemical industry pipes, etc.

Boiler pipe materials and standards

Standards and material for steel pipe is available at carbon, alloy, and stainless steel material.

Carbon steel: ASTM/ASME A/SA 106, ASTM A179, ASTM A192, ASTM/ASME A/SA 210, ASTM A333 Gr 1, 6,7 to Gr 9,

Alloy steel: ASTM/ASME A/SA 213 T1, T2, T5, T9, T11, T12, T22, T91, T92; ASTM A335 P1, P2, P5, P9, P11, P12, P22, P91, P92

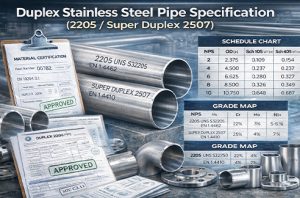

Stainless Steel: ASTM A268, ASTM A213, TP304/L, TP316/L, 310S,309S,317,317L,321,321H, and duplex stainless steel material etc.

Common Sizes: OD from 6mm to 1240mm, thickness from 1mm to 50mm

Types: Straight boiler pipe, and U boiler steel pipe for tube exchanger bundle.

These standards specify the classification, size, shape, weight and allowable deviation, technical requirements, inspection and test, packaging, marking and quality certificate of seamless steel tubes for boiler.

Boiler Pipe Size

Boiler pipe size range complied with the different ASTM standard required. Like ASTM A106 or ASTM 179, 192 etc.

But most of the boiler pipe size is small, outer diameter usually less than 1 1/2” (1/4”, 1/2”, 3/4”, 1” and 1 1/2”). Then 2”, 2 1/2”, 3” and maximum to 4”.

Medium and high pressure boiler pipe differences

Based on different working temperature, the medium or high pressure boiler pipe shall be used. Normally classified as below cases:

a. The operation temperature of general boiler pipe is lower than 450℃. The medium pressure boiler pipeline mainly adopts hot rolling process or cold drawing process.

b. High pressure boiler pipes are often used in high temperature and high pressure conditions. Under the action of high temperature flue gas and steam, the pipe will occur oxidation and corrosion. It is required high pressure boiler pipe that has high durable strength, high oxidation corrosion resistance and good tissue stability.

Boiler Pipe Manufacturing methods

The manufacturing method of medium and high pressure boiler steel pipe is same with the seamless steel pipe, but there are some key manufacturing processes shall be noted:

Fine drawing, surface bright, hot rolling, cold drawn, heat expansion

Heat treatment methods applied in the boiler pipes

Heat treatment is a method of changing the physical properties of high pressure boiler pipe by heating and cooling. Heat treatment can improve the microstructure of high pressure boiler pipe, so as to meet the required physical requirements. Toughness, hardness and wear resistance are obtained by heat treatment. In order to obtain these characteristics, it is necessary to adopt quenching, annealing, tempering and surface hardening.

a. Quenching

Hardening, also called quenching, is that high pressure boiler pipe is heated evenly to the appropriate temperature, then quickly immerse in water or oil for rapid cooling, and cooling in the air or in the freezing zone. So that the high pressure boiler pipe can obtain the required hardness.

b. Tempering

High pressure boiler pipe will become brittle after hardening. And the stress caused by quenching can make the high pressure boiler pipe tapped and broken. The tempering method can be used to eliminate brittleness. Although the hardness of high pressure boiler pipe is lighter reduced, its the toughness can be increased to reduce the brittleness.

c. Annealing

Annealing is the method to eliminate the internal stress of high pressure boiler pipe. The annealing method is that the steel parts need to be heated to the critical temperature, then put in dry ash, lime, asbestos or closed in the furnace, then let it cooling slowly.

The basic method of rust removal

a. Cleaning

Using the solvent and emulsion to clean the surface of high pressure boiler pipe, so as to achieve the purpose of removing oil, grease, dust, lubricant and similar organic matter. But it cannot remove the dust, oxide skin, welding medicine and so on. So it is only as a supplementary method in the anti-corrosion production.

b. Tool

Tool rust removal mainly use wire brush and other tools to grind the surface of high pressure boiler pipe. It can remove loose or warping of the oxide skin, rust, welding slag and so on. Manual tool can reach SA2 level, power tool can reach SA3 level. If the iron oxide scale attached to the surface, it cannot reach the anchorage depth required by the anti-corrosion construction.

c. Acid cleaning

High pressure boiler pipe generally adopt chemical and electrolytic methods to do pickling treatment.

d. Spray rust removal

Spray rust removal cannot only remove rust, oxide and dirt completely, but also high pressure boiler pipe can achieve the required uniform roughness under the action of abrasive impact and friction force.

Spay rust removal cannot only expand the physical adsorption on the surface of high pressure boiler pipe, but also enhance the mechanical adhesion between the anti corrosion layer and the pipe surface. So spray rust removal is ideal method of rust removing for pipeline corrosion.

In Summary

The reliability of a boiler system depends heavily on the quality of its tubing. By delivering consistent performance under extreme pressure and temperature fluctuations, boiler steel pipes ensure the stable operation of power plants, refineries, and industrial heat exchangers. Their ability to resist creep, oxidation, and thermal fatigue makes them indispensable for facilities that cannot afford downtime or structural failure.

As a global supplier, Octal Steel provides certified medium-pressure and high-pressure boiler steel pipes manufactured in strict accordance with ASTM, ASME, and EN standards. Each pipe undergoes rigorous quality inspections and is supplied with complete documentation, including mill test certificates (MTC) and traceability reports. For clients across the energy and petrochemical sectors, Octal Steel delivers not only high-quality boiler tubing but also long-term reliability and technical assurance essential for critical operations.