CRA Clad, Lined, Weld Overlay Pipe Cladding- Bimetal Pipes

What is clad pipe

In CRA service, clad pipe meaning refers to a bimetal (bimetallic) pipe construction that combines a carbon steel backing pipe for strength with a corrosion-resistant alloy layer or liner on the wetted surface for corrosion protection. In project language, this is often written as CRA pipe, CRA clad, CRA clad pipe (sometimes typed as cra clad.) and CRA lined / overlay solutions, depending on how the CRA is applied.

Solid CRA lined pipes or CRA clad (cladding) pipes are known as bimetal pipe that consist of an inner alloy pipe for corrosion-resistance and an outer carbon steel pipe which can withstand external and internal pressure.

In highly aggressive media such as sour gas, H₂S, CO₂, chloride brines, and saline water reinjection systems, standard carbon steel pipelines often fail prematurely due to corrosion. CRA (Corrosion-Resistant Alloy) clad, lined, and weld overlay pipes provide a robust solution by combining the structural strength of carbon steel with a corrosion-resistant layer or liner of higher-performance alloys. These bimetallic pipes consist of an inner CRA layer (e.g., stainless steel 316L, Inconel 625, alloy 825, duplex alloys) welded or bonded to a carbon steel base pipe (e.g., API 5L, ASTM A106/A53, ASTM A333 Grade 6).

-

In a clad configuration, the CRA alloy is metallurgically bonded to the carbon steel via methods such as explosive bonding, roll bonding, or weld overlay.

-

In a lined configuration, the CRA alloy pipe is mechanically expanded, press-fitted, or bonded inside the carbon steel backing pipe using full-length expanders, hydroforming, or similar techniques.

-

CRA weld overlay uses alloy welding rods to deposit a corrosion-resistant layer onto the internal surface of the carbon steel pipe.

These composite pipes are widely used in applications such as water injection pipelines, interfield flowlines, riser pipelines, and subsea flowlines, where long-term resistance to internal corrosion is critical. Octal Steel supplies CRA clad and lined pipes, fittings, and flanges with outer diameters from 6″ to 60″ (clad) and 1/2″ to 24″ (lined), CRA thickness up to 80 mm (clad) and 7–35 mm (lined), and maximum lengths up to 12.3 meters.

Where CRA composite pipes fit in the field: CRA composite pipe selection typically anchors on internal medium severity (CO₂/H₂S/chlorides), operating temperature, pressure, and expected service life. CRA clad, lined, and overlay solutions are commonly specified when solid CRA pipe cost is not justified across the full line length, but internal corrosion risk remains non-negotiable.

how to do pipe cladding

Bonding and cladding processes for CRA cladding and lined pipe.

Clad pipe manufacturing process (overview): The “pipe cladding” scope usually covers (1) selecting the CRA layer / liner material, (2) bonding the CRA to the carbon steel backing pipe (metallurgical bond, mechanical bond, or weld overlay), (3) welding and dimensional control, and (4) inspection and documentation closure aligned to the specified standard and project acceptance package.

Normally, the mother pipe in carbon steel is of API 5L B to X70, ASTM A53B, or A106B. Clad or lined is with alloy steel of 316L or Inconel alloy 625 / Inconel 625 / UNS N06625, alloy 825, UNS31803, UNS 31254.

CRA Clad and Lined pipe API 5L X65 with 316L

Pipes made from CRA (Corrosion-Resistant Alloy) materials have a wide range of applications. These include subsea pipelines used for transporting sour gas and oil, saltwater pipelines, water reinjection systems, process pipes in the chemical industry, saltwater pipes, and many others.

These CRA lined and clad steel pipes are majorly used as:

-Water injection pipelines

Used to move treated or filtered seawater / produced water from pumps to injection wells at sustained pressure, where oxygen residuals, chlorides, and biocide chemistry can accelerate corrosion in carbon steel. CRA clad or lined construction is selected to keep the internal wetted surface corrosion-resistant while retaining the pressure capacity of the carbon steel backing pipe, especially in long injection headers and trunk lines.

-Inter-field pipelines

Applied on tie-in lines between wells, manifolds, and processing facilities that carry multiphase flow (oil, gas, produced water) with CO₂ and, in many fields, H₂S. These lines often see variable flow regimes and water cut increases over time, which drives localized corrosion risk. CRA composite pipes are used to maintain internal corrosion resistance without using solid CRA pipe across the entire interfield network.

-Riser pipelines

Used as production or injection risers where internal corrosion resistance must be maintained under combined mechanical loading and aggressive media. Riser service typically demands stable internal surface protection over long operating periods, and CRA lined/clad options are commonly applied to manage corrosion risk while keeping the structural role on the carbon steel side.

-Flow-lines

Used for production flow-lines that transport corrosive fluids from wells to manifolds or processing units, including wet gas, sour service, or high-chloride produced water. CRA clad/lined pipes are specified when the corrosion mechanism is dominated by internal exposure and long-term integrity depends on maintaining a continuous CRA barrier on the wetted surface, while the base pipe provides the primary load-bearing section.

Octal offers high quality CRA clad and lined pipe.

Acceptance-facing definition (engineer + inspection): In CRA composite piping, “high quality” is demonstrated through controlled bonding quality, overlay chemistry / thickness consistency (where applicable), dimensional conformity, and a documentation set that ties heat numbers and inspection results to each pipe / spool.

Mechanical bonding

Mechanical bonding method is to use an expanding machine to expand the inner alloy pipe to outer carbon steel pipe.

Mechanical bond acceptance focus: Mechanical bonding performance is typically demonstrated through stable contact along the full interface length, controlled ovality/roundness, and repeatable bonding results by process control (expander die position control or hydroforming controls), aligned to the specified lined-pipe standard and project requirements.

CRA Overlay / Weld Overlay

CRA weld overlay methods

CRA Weld overlay Pipe involves the use of an alloy welding rod (cladding material) to weld an overlay onto the internal surface of a carbon steel pipe. This overlay essentially serves to overwrite the alloy steel onto the carbon steel pipe.

Clad pipe welding (overlay) acceptance focus: Weld overlay performance is typically evaluated by overlay thickness uniformity, continuity (no exposed carbon steel at the wetted surface), chemistry/dilution control, and agreed NDT scope. For critical service, overlay mapping and inspection records are commonly used to close acceptance and handover.

Methods of Bonding CRA material to carbon steel pipe

In terms of bonding the CRA material to carbon steel, there are two methods to go about it:

1. Metallurgical bond (for CRA Clad Pipes) – Cladding of plates (metallurgical bond between two different metals) can be carried out by various operations such as coextrusion, hot rolling, explosive bonding or weld overlay. However, one of the major challenges with metallurgical bonding is the high cost associated with it. This is mainly due to the limited number of suppliers who can perform the complex and demanding manufacturing process required for metallurgical bonding of the plates.

2. Mechanical bond (for CRA Lined pipes) – Mechanical bonding the CRA pipe and the backing steel pipe by using spring back variation which can be achieved by means of Hydroforming or full-length pipe expander.

3. CRA Weld Overlay.

Supplier capability note: When projects compare clad pipe manufacturers (sometimes misspelled in searches as cald pipe manufacturers), practical differentiators are process route capability (clad / lined / overlay), size range, CRA thickness control, repeatable bonding results, and completeness of inspection documentation for acceptance.

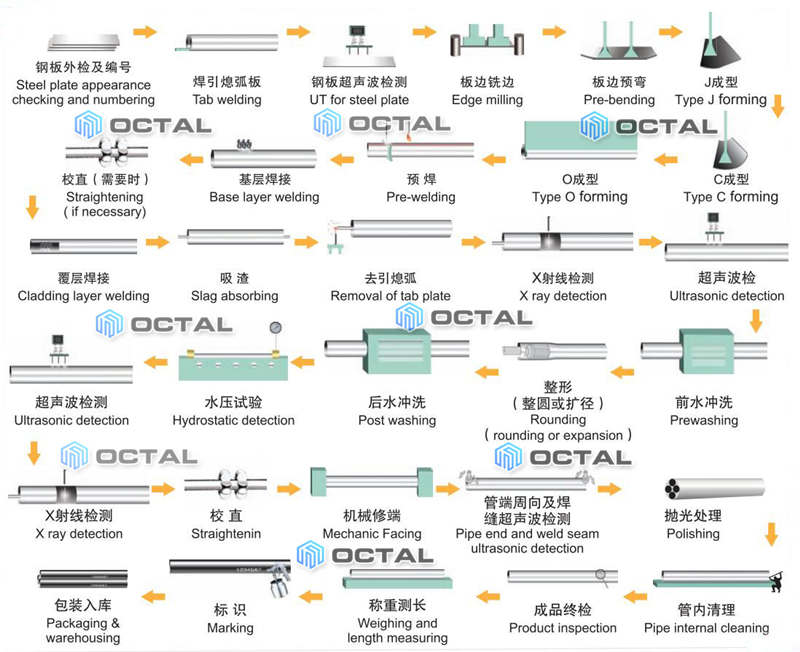

Pipe Cladding Key Process

The key process in cladding (clad) pipe production involves the use of metallurgical methods such as weld overlay or co-extrusion for bonding. The first step is to clad the CRA (Corrosion-Resistant Alloy) material onto a steel plate. Then, the cladding steel plate is formed into a pipe shape and welded to complete the clad pipe.

Clad pipe manufacturing process (step chain): CRA plate / layer preparation → bonding to backing steel (clad / overlay) → forming → seam welding → dimensional control → NDT → final inspection and documentation closure. This step chain is often used to define scope and acceptance points on clad projects.

Using CRA plate to make the pipe

CRA clad lined pipe process bimetal

Clad pipe material alignment: CRA plate (or deposited overlay metal) selection is normally driven by corrosive mechanism (CO₂/H₂S/chlorides), operating temperature, flow regime, and required design life, with the backing steel selected to satisfy pressure containment and structural needs.

Bonding Process of CRA lined pipes

To bond CRA lined pipes using a Full-Length Pipe Expander, the outer and inner pipe are aligned in a telescopic manner. They are then positioned on the outfeed and infeed loading cart respectively. The pipe is gradually fed using the loading cart over the expanding head.

In order to achieve consistent mechanical bonding between the outer and inner pipe across the entire contact area, a specialized expander head design is utilized. The Full-Length Pipe Expander is equipped with a linear transducer that precisely measures the position of the dies. This allows for the attainment of the optimal point in mechanical bonding for each combination of outer and inner pipe materials.

CRA Clad and Lined pipe API 5L X65 with 316L

Field-fit implication: Controlled expansion and calibration support predictable roundness and interface contact, which matters for spool fit-up, welding alignment, and downstream inspection acceptance—especially where dimensional tolerances and internal liner integrity are inspected.

Full-Length Pipe Expander vs Hydroforming Machine for CRA Lined Pipe

Some manufacturers utilize Hydroforming machines for bonding operations. However, when comparing the Full-Length Pipe Expander to the Hydroforming machine, it becomes evident that the latter is more expensive. Additionally, the Hydroforming machine has costly tooling and often results in material waste due to the seals used on the pipe ends.

Companies like Fontijne Grotnes offer a more economical and controlled solution in the form of the Full-Length Pipe Expander. This equipment allows for optimum mechanical bonding between the outer and inner pipe combinations. The process is facilitated by diameter position control, eliminating the need for expensive outer dies.

This process guarantees a constant production process according to API 5L through:

-Improving mechanical properties by exceeding its material yield strength

-Stress relief of material in way of the weld zone

-Pipe weld steam testing

-Pipe straightening

-Pipe calibration over its full length in diameter and roundness

Market Growth for cladding and lined pipe

The demand for CRA clad and lined pipes is increasing due to the anticipated rise in corrosive conditions. This is primarily driven by the higher water cuts and concentrations of carbon dioxide and hydrogen sulfide in produced fluids. Additionally, these corrosive products often need to be transported over long distances, at higher pressures, and in an environmentally friendly manner.

Inconel Alloy 625 Weld Overlay / Alloy 625 Clad Pipe and Lined Pipe

Inconel alloy 625, which is a Ni-Cr based material, has been proven to possess high corrosion resistance in a wide range of environments, including marine, aerospace, chemical plants, and petrochemical industries. It exhibits exceptional resistance to various highly corrosive environments and offers advanced mechanical properties at both low and high temperatures.

Cladding or lining the inside of a carbon steel pipe with Inconel alloy 625 material has become a popular solution for addressing corrosive issues and achieving significant cost savings.

Clad pipe material mapping: Alloy 625 is frequently selected for aggressive internal corrosion environments where chloride exposure, sour conditions, and elevated temperature combine, and where long-term internal corrosion resistance is required without the cost of full solid CRA pipe.

Our Supplied Range (Structured Table)

| Item | Details |

|---|---|

| Supply scope | CRA Clad and Lined pipes, Fittings, Flanges |

| Clad / lined standard | API 5LD, API 5LC |

| Outer Diameter (cladding pipe) | 6” to 60” |

| OD range (CRA lined pipe) | 1/2” to 24” |

| Thickness | Up to 80 mm (Clad pipe), 7 mm to 35 mm (For lined pipe) |

| Maximum length | 12.3 meter |

| Backing steel pipe (mother pipe) material | Carbon Steel Pipe, C-Mn Steel Pipe, API 5L B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1, PSL2 and SOUR NACE MR0175, ASTM A106 B, ASTM A333 Grade 6, etc. |

| CRA Clad Pipe Fittings | Elbow, Cap, Tee, Reducer in ASME B16.9, Material in ASTM A234WPB, WPC, ASTM A420 WPL6. |

| CRA Clad Flange | Welding Neck Flange, Slip On Flange in ASME B16.5, B16.47 A/B, Material in ASTM A105, A350. |

| Cladding and Lining CRA material | Austenitic stainless steel, nickel alloy steel, Hastelloy C276, Inconel Alloy 625 (Inconel 625 weld overlay), 825, S31803, S31254, titanium alloy steel, duplex steel, and etc. |

Clad Pipe Insulation vs CRA Cladding (Insulation Cladding / Aluminum Cladding)

The word “cladding” is used in two different engineering contexts:

CRA cladding / CRA lined / weld overlay (CRA pipe scope): internal corrosion protection achieved by CRA layers, liners, or overlays bonded to a carbon steel backing pipe.

Clad pipe insulation / metal clad pipe insulation (insulation cladding scope): external thermal insulation protected by metal jacketing, often called aluminum cladding or stainless steel jacketing.

In piping specifications, clad pipe insulation refers to the insulation system outside the pipe, while CRA cladding refers to the corrosion-resistant layer inside the pipe

How to Install Pipe Insulation (Metal Jacketing / Insulation Cladding Sequence)

The phrase how to install pipe insulation typically refers to the standard insulation cladding sequence used on industrial piping: insulation sections installed and jointed over the pipe, followed by metal jacketing installation (often aluminum cladding), controlled overlap direction and fastening, sealing of seams to limit water ingress, and inspection of terminations and penetrations to maintain a continuous protective jacket. This sequence is commonly specified for metal clad pipe insulation systems exposed to weather, splash, or mechanical damage.

Engineered Corrosion Protection for Critical Pipelines

CRA clad, lined, and weld overlay pipes offer engineered solutions for pipeline systems where corrosion resistance is non-negotiable. By integrating a durable alloy layer with a structural carbon steel base, these bimetallic pipes deliver both mechanical strength and chemical durability, even under severe service conditions such as sour gas, high CO₂, or chloride-laden flows.

Octal Steel provides a full portfolio of CRA clad & lined solutions, including matching clad pipe fittings, flanges, and full documentation (MTC, NDT reports, bond strength certificates) for major standards like API 5LD, API 5LC, and ASME/ASTM codes. Whether your project demands high-performance internal corrosion resistance or cost-effective structural support, choosing Octal Steel’s CRA clad & lined pipe systems ensures long-term reliability and integrated protection across critical pipeline networks.

FAQ

Q1: What is clad pipe and what is the clad pipe meaning in CRA projects?

A1: A clad pipe is a bimetal pipe combining a carbon steel backing pipe with a corrosion-resistant alloy layer or liner on the wetted surface; clad pipe meaning in CRA projects refers to internal corrosion protection achieved by CRA clad, CRA lined, or weld overlay construction.

Q2: What is the difference between CRA clad pipe, CRA lined pipe, and CRA weld overlay?

A2: CRA clad pipe uses a metallurgical bond between the CRA layer and carbon steel; CRA lined pipe uses mechanical bonding by expansion or hydroforming of a CRA liner inside the backing pipe; CRA weld overlay deposits an alloy layer by controlled welding onto the internal surface.

Q3: What are typical clad pipe material options for the CRA layer or liner?

A3: Common clad pipe material selections include stainless steel 316L, nickel alloys such as Inconel Alloy 625 (UNS N06625) and Alloy 825, and duplex / high-alloy stainless grades, paired with carbon steel mother pipes such as API 5L or ASTM carbon steel pipe.

Q4: What is clad pipe insulation and how does it relate to insulation cladding or aluminum cladding?

A4: Clad pipe insulation refers to external thermal insulation protected by metal jacketing; insulation cladding or aluminum cladding describes the metal jacket over the insulation, which is a different engineering scope from CRA internal cladding used for corrosion protection.