CRA Clad, Lined, Weld Overlay Pipe Cladding- Bimetal Pipes

Solid CRA lined pipes or CRA clad (cladding) pipes are known as bimetal pipe that consist of an inner alloy pipe for corrosion-resistance and an outer carbon steel pipe which can withstand external and internal pressure.

Normally, the mother pipe in carbon steel is of API 5L B to X70, ASTM A53B, or A106B. Clad or lined is with alloy steel of 316L or Inconel alloy 625 / Inconel 625 / UNS N06625, alloy 825, UNS31803, UNS 31254.

Pipes made from CRA (Corrosion-Resistant Alloy) materials have a wide range of applications. These include subsea pipelines used for transporting sour gas and oil, saltwater pipelines, water reinjection systems, process pipes in the chemical industry, saltwater pipes, and many others.

These CRA lined and clad steel pipes are majorly used as:

-Water injection pipelines

-Interfield pipelines

-Riser pipelines

-Flow-lines

Octal offers high quality CRA clad and lined pipe.

Mechanical bonding

Mechanical bonding method is to use an expanding machine to expand the inner alloy pipe to outer carbon steel pipe.

CRA Overlay / Weld Overlay

CRA Weld overlay Pipe involves the use of an alloy welding rod (cladding material) to weld an overlay onto the internal surface of a carbon steel pipe. This overlay essentially serves to overwrite the alloy steel onto the carbon steel pipe.

Methods of Bonding CRA material to carbon steel pipe

In terms of bonding the CRA material to carbon steel, there are two methods to go about it:

1. Metallurgical bond (for CRA Clad Pipes) – Cladding of plates (metallurgical bond between two different metals) can be carried out by various operations such as coextrusion, hot rolling, explosive bonding or weld overlay. However, one of the major challenges with metallurgical bonding is the high cost associated with it. This is mainly due to the limited number of suppliers who can perform the complex and demanding manufacturing process required for metallurgical bonding of the plates.

2. Mechanical bond (for CRA Lined pipes) – Mechanical bonding the CRA pipe and the backing steel pipe by using spring back variation which can be achieved by means of Hydroforming or full-length pipe expander.

3. CRA Weld Overlay.

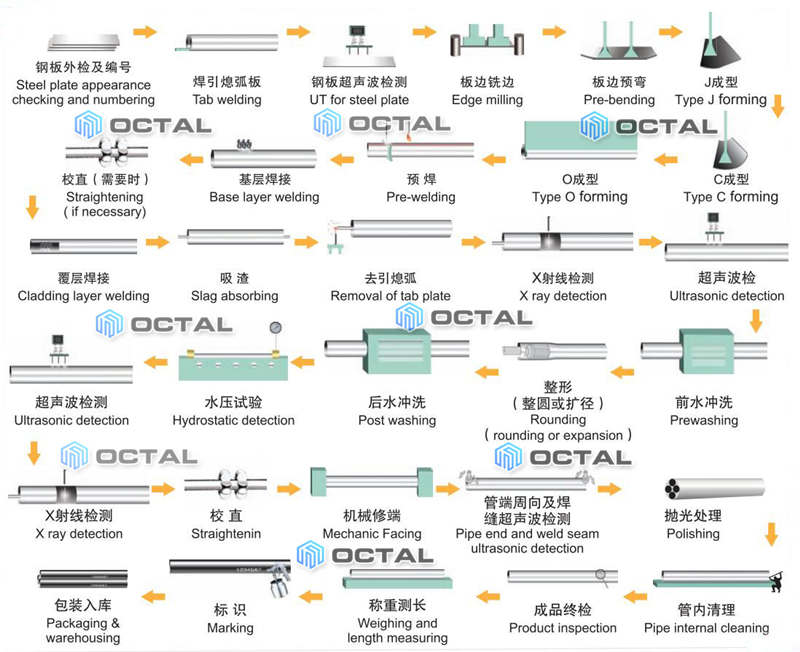

Pipe Cladding Key Process

The key process in cladding (clad) pipe production involves the use of metallurgical methods such as weld overlay or co-extrusion for bonding. The first step is to clad the CRA (Corrosion-Resistant Alloy) material onto a steel plate. Then, the cladding steel plate is formed into a pipe shape and welded to complete the clad pipe.

Using CRA plate to make the pipe

Bonding Process of CRA lined pipes

To bond CRA lined pipes using a Full-Length Pipe Expander, the outer and inner pipe are aligned in a telescopic manner. They are then positioned on the outfeed and infeed loading cart respectively. The pipe is gradually fed using the loading cart over the expanding head.

In order to achieve consistent mechanical bonding between the outer and inner pipe across the entire contact area, a specialized expander head design is utilized. The Full-Length Pipe Expander is equipped with a linear transducer that precisely measures the position of the dies. This allows for the attainment of the optimal point in mechanical bonding for each combination of outer and inner pipe materials.

Full-Length Pipe Expander vs Hydroforming Machine for CRA Lined Pipe

Some manufacturers utilize Hydroforming machines for bonding operations. However, when comparing the Full-Length Pipe Expander to the Hydroforming machine, it becomes evident that the latter is more expensive. Additionally, the Hydroforming machine has costly tooling and often results in material waste due to the seals used on the pipe ends.

Companies like Fontijne Grotnes offer a more economical and controlled solution in the form of the Full-Length Pipe Expander. This equipment allows for optimum mechanical bonding between the outer and inner pipe combinations. The process is facilitated by diameter position control, eliminating the need for expensive outer dies.

This process guarantees a constant production process according to API 5L through:

-Improving mechanical properties by exceeding its material yield strength

-Stress relief of material in way of the weld zone

-Pipe weld steam testing

-Pipe straightening

-Pipe calibration over its full length in diameter and roundness

Market Growth for cladding and lined pipe

The demand for CRA clad and lined pipes is increasing due to the anticipated rise in corrosive conditions. This is primarily driven by the higher water cuts and concentrations of carbon dioxide and hydrogen sulfide in produced fluids. Additionally, these corrosive products often need to be transported over long distances, at higher pressures, and in an environmentally friendly manner.

Inconel Alloy 625 Weld Overlay / Alloy 625 Clad Pipe and Lined Pipe

Inconel alloy 625, which is a Ni-Cr based material, has been proven to possess high corrosion resistance in a wide range of environments, including marine, aerospace, chemical plants, and petrochemical industries. It exhibits exceptional resistance to various highly corrosive environments and offers advanced mechanical properties at both low and high temperatures.

Cladding or lining the inside of a carbon steel pipe with Inconel alloy 625 material has become a popular solution for addressing corrosive issues and achieving significant cost savings.

Our Supplied Range:

We supply CRA Clad and Lined pipes, Fittings, Flanges:

Clad or Lined standard: API 5LD, API 5LC

Outer Diameter Cladding pipe: 6” to 60”

OD range for CRA lined pipe: 1/2” to 24”

Thickness: Up to 80 mm (Clad pipe), 7 mm to 35 mm (For lined pipe)

Maximum length: 12.3 meter

Backing steel pipe (mother pipe) material: Carbon Steel Pipe, C-Mn Steel Pipe, API 5L B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1, PSL2 and SOUR NACE MR0175, ASTM A106 B, ASTM A333 Grade 6, etc.

CRA Clad Pipe Fittings: Elbow, Cap, Tee, Reducer in ASME B16.9, Material in ASTM A234WPB, WPC, ASTM A420 WPL6.

CRA Clad Flange: Welding Neck Flange, Slip On Flange in ASME B16.5, B16.47 A/B, Material in ASTM A105, A350.

Cladding and Lining CRA (Corrosion resistant alloy) material: Austenitic stainless steel, nickel alloy steel, Hastelloy C276, Inconel Alloy 625 (Inconel 625 weld overlay), 825, S31803, S31254 titanium alloy steel duplex steel, and etc.