LSAW Pipe and SSAW Pipe Specifications, Differences

Difference between LSAW and SSAW Pipes

Pipelines that transport oil, gas, water, or other fluids rely heavily on welded steel pipes, particularly LSAW (Longitudinal Submerged Arc Welding) and SSAW (Spiral Submerged Arc Welding) pipes. Although both utilize submerged arc welding technologies, the distinction in their welding orientations leads to significant differences in mechanical behavior, dimension control, defect propensity, and application scope. Understanding these differences is essential for pipeline engineers, project planners, and procurement specialists who must match materials to service conditions with precision.

LSAW pipes are formed from steel plates bent and welded longitudinally to produce a seam that runs parallel to the pipe’s axis, offering superior straightness, weld uniformity, and controlled mechanical properties. Their design makes them ideal for high-pressure pipelines and critical infrastructure spanning long distances. SSAW pipes, in contrast, are produced by spirally welding a steel strip at a preset helix angle, which allows a single strip width to yield different diameters. This versatility enhances material utilization and cost effectiveness but introduces additional considerations in seam stress behavior and defect control.

This FAQ dives into the key specifications, manufacturing principles, advantages, and limitations of LSAW and SSAW pipes, and guides selection based on field conditions such as pressure class, installation route, defect risk, and regulatory acceptance.

What is LSAW Pipe

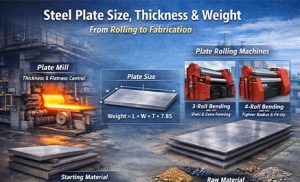

LSAW Pipe, or Longitudinal Submerged Arc-Welding Pipe (also known as SAWL pipe), is manufactured using steel plates as the raw material. The plates are shaped using a molding machine and then undergo double-sided submerged arc welding. This process imparts the LSAW steel pipe with superior ductility, weld toughness, uniformity, plasticity, and excellent sealing properties.

Diameters range and performances of LSAW pipe

The diameter range of LSAW pipes is broader than that of ERW pipes, typically spanning from 16 inches to 60 inches (406 mm to 1500 mm). They demonstrate excellent performance in terms of high-pressure resistance and low-temperature corrosion resistance.

Octal has LSAW pipe on sale.

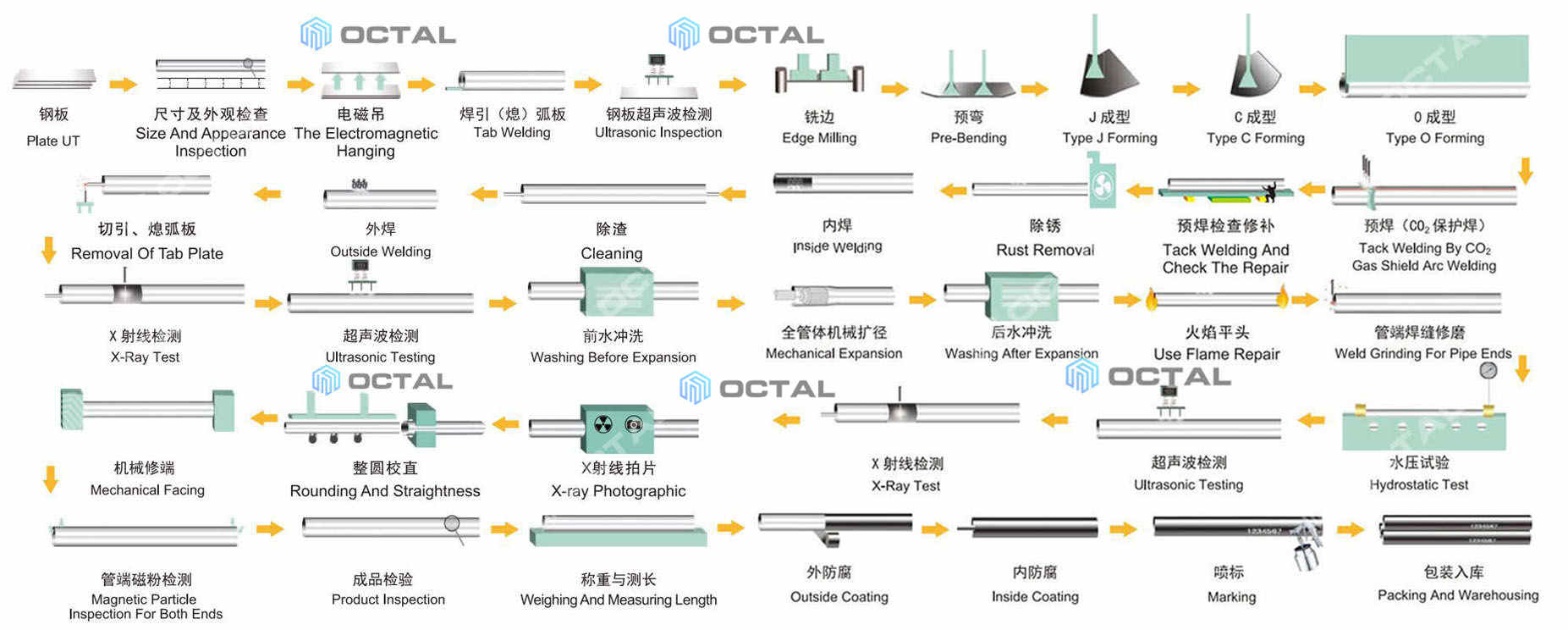

LSAW Pipe/SAWL Pipe (JCOE Pipe) Manufacturing Flow Chart

LSAW Pipe Moulding Machine

LSAW pipe moulding machine

LSAW Pipe Manufacturing Video

Applications of LSAW pipe

LSAW pipes are extensively used in oil and gas pipelines, particularly where large diameter and thick-walled pipes with high strength are required for long-distance transportation. They are also utilized in construction projects that demand robust strength, such as water treatment facilities, thermal industries, and bridge construction. According to API specifications, LSAW pipes (also known as SAWL pipes or JCOE pipes) are specifically designed for large-scale oil and gas transportation, especially in scenarios where pipelines traverse urban areas, cities, and seas. These applications fall under class 1 and class 2 areas.

SSAW Pipe (HSAW Pipe)

SSAW Pipe, or Spiral Submerged Arc-Welding Pipe (also known as HSAW pipe or Helical SAW), features a welding seam that resembles a helix. It employs the same submerged arc welding technology used in LSAW pipes; however, the key difference lies in the welding method. While LSAW pipes are welded longitudinally, SSAW pipes are spiral welded. The manufacturing process involves rolling a steel strip at an angle to the pipe’s centerline, which creates a spiral welding seam during the forming and welding stages.

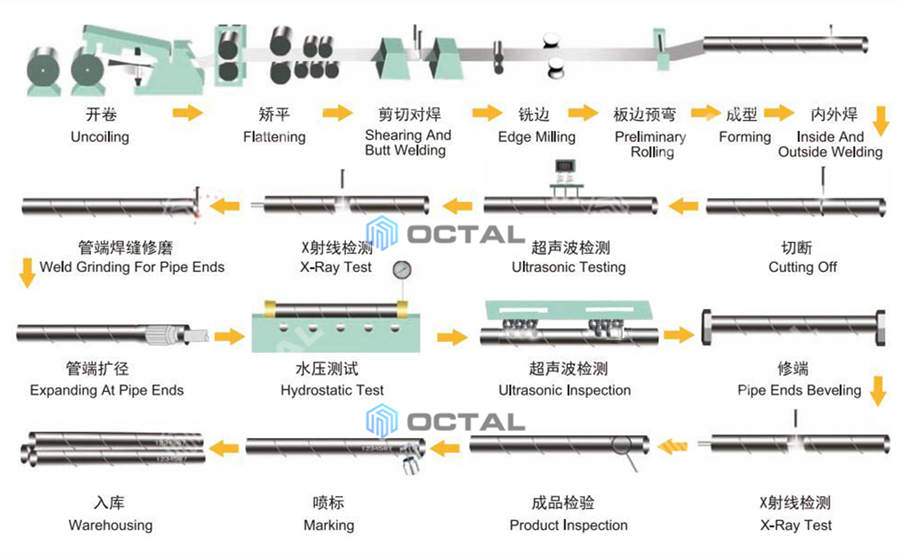

SSAW Pipe Manufacturing Flow Chart

SSAW Pipe Manufacturing Video

SSAW pipe (HSAW Pipe) Size range and Features

The diameter range of SSAW pipes spans from 20 inches to 100 inches (406 mm to 2540 mm). One of the key advantages is that we can produce various diameters of SSAW pipes using the same size steel strip, allowing for versatile applications of the raw material. Additionally, the welding seam is designed to minimize primary stress, providing good performance under stress conditions.

However, there are some disadvantages, including challenges with physical dimensions. The length of the welding seam is longer than the pipe itself, which can lead to defects such as cracks, air holes, cinder inclusion, partial welding, and issues with welding force during the pulling process.

Applications of SSAW pipe

For oil and gas pipeline systems, the petroleum design specifications restrict the application of SSAW pipes (HSAW pipes) to class 3 and class 4 areas. Additionally, these pipes are used in construction structures, water transportation, sewage treatment, the thermal industry, and various building projects.

LSAW Pipe better than SSAW Pipe

LSAW (Longitudinal Submerged Arc-Welding) pipes are often considered superior to SSAW (Spiral Submerged Arc-Welding) pipes for several reasons:

- Welding Quality: LSAW pipes are welded longitudinally, which typically results in a more uniform and consistent weld seam. This can lead to better mechanical properties and reduced risk of defects compared to the spiral welds found in SSAW pipes.

- Strength and Durability: The longitudinal weld in LSAW pipes generally provides higher strength and better resistance to internal pressure. This makes them more suitable for high-pressure applications, such as in critical oil and gas pipelines.

- Dimensional Accuracy: LSAW pipes tend to have better dimensional accuracy and straightness compared to SSAW pipes. This can facilitate easier installation and alignment in pipeline projects.

- Thickness Range: LSAW pipes can be produced in thicker wall sections than SSAW pipes, making them more suitable for applications that require enhanced strength and durability.

- Application Versatility: LSAW pipes are often preferred for high-stress applications, including those in urban areas and critical infrastructure, where reliability is paramount.

- Regulatory Acceptance: Many regulatory bodies and industry standards favor LSAW pipes for key pipeline projects, leading to broader acceptance in critical applications compared to SSAW pipes.

- Reduced Risk of Defects: The manufacturing process of LSAW pipes minimizes the risk of defects such as cracks, air holes, and inclusions, which can be more prevalent in SSAW pipes due to their spiral welding process.

Overall, while both LSAW and SSAW pipes have their applications, LSAW pipes are often favored for their superior mechanical properties, quality, and suitability for high-pressure and critical applications.

Why Choose Octal Pipe

When choosing between LSAW pipe and SSAW pipe, the decision should be based on a comprehensive assessment of pipeline route, pressure rating, defect tolerance, and lifetime performance. For high-pressure trunklines and critical oil & gas transmission projects, LSAW often holds the advantage due to its superior weld uniformity, dimensional accuracy, and lower defect probability. SSAW pipes remain competitive in large-diameter, lower-pressure contexts where material efficiency and cost optimization are prioritized.

Octal Steel provides both LSAW and SSAW pipes manufactured under stringent quality control and in compliance with industry standards. With full traceability, rigorous testing, and expert technical support, Octal Steel ensures that your pipeline design aligns with operational reliability, safety requirements, and cost targets. Choosing the right pipe type is not merely a material decision—it is a strategic foundation for the long-term success of your infrastructure projects.