FAQ

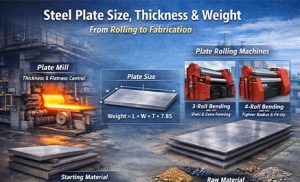

Steel Plate Size, Thickness & Weight: From Rolling to Fabrication

Steel plate is flat-rolled steel delivered as individual plates (not coil) for fabrication where thickness stability, flatness, and verified mechanical properties must remain consistent through cutting, forming, welding, and inspection. In project packages, steel plate is often treated as a starting material for downstream manufacturing, where the process route and plate category can matter as […]

Pipe Connection Reliability and Sealing Controls for Steel Piping Systems

A stable pipe connection is built when joint geometry is repeatable, sealing load is repeatable, and the acceptance evidence is already defined before fabrication starts. In steel piping projects, the highest rework risk concentrates at interfaces—where tolerances stack up across pipe, pipe connection fittings, and assembly practice. What procurement is really buying: a “joint package” […]

API 5L B PSL2 Seamless Steel Pipe Manufacturing Process

Our company employs advanced integrated steel smelting processes to produce API 5L B PSL2 seamless steel pipes. From raw material processing to final product delivery, the entire process strictly follows international standards. Our smelting process includes blast furnace ironmaking, converter steelmaking, refining treatment, continuous casting, and subsequent rolling operations, ensuring stable and reliable product quality. […]

API 5L PSL1 and PSL2 Differences for the Steel Line Pipe

API 5L line pipe (Seamless and welded pipe) of all grades have PSL1 and PSL2 two product specifications, they are different on chemical composition, manufacturing processes, mechanical strength, heat treatment, test records, traceability etc. Line pipes in API 5L PSL2 is higher than PSL1 a. PSL is the short name of product standard level. The product […]

What is Common Defects for Welded Steel Pipes

For welded and seamless steel pipes, no matter how perfectly designed and fabricated they are, would certainly have some defects in some areas. A welded defect is a flaw that inhibits the usefulness of the steel pipe and there is a wide range of these effects with causes. Testing method for the defects on the […]

Steel Sucker Rod and Pony Rod Differences

What is API 11B Steel Sucker Rod Steel sucker rod is a kind of long slender bar used in pumping well, common standard is API SPEC 11B (Specification for sucker rods, polished rods and liners, couplings, sinker bars, polished rod clamps, stuffing boxes, and pumping tees). It connects with polished bar above, and pumps at […]

Fire Protection Pipe and Connection Fittings

The fire protection pipe and connection fittings are mainly used to connect firefighting equipment, conveying fire fighting water and so on. It is also called fire sprinkler pipe and fittings. Due to the special requirements, the thickness and material of the fire protection pipe and fittings have special requirements. According to the regulations, the fire […]

Galvanized Rigid Steel/Metallic Conduit Pipe (GRC)

1. What is Galvanized rigid steel pipe conduit Galvanized rigid steel conduit is manufactured from mild steel, it is used as a steel raceway system for electric conductors. The shape is circular cross-section, designed for the physical protection and routing of wire conductors and use as an equipment grounding conductor. Galvanized rigid steel conduit is […]

Things you need to know about hot dipped galvanized steel pipe

In the realm of steel protection engineering, Hot-Dipped Galvanizing (HDG) represents a classic, century-proven corrosion control strategy that remains irreplaceable. Its technical essence is far more than a simple surface coating; it is a complex process involving physics, chemistry, and metallurgy. The core principle involves immersing a meticulously prepared steel pipe (after pickling and fluxing) […]

Differences between 3PE (3LPE Coated Pipe) and FBE Epoxy Coating Pipe

Differences between 3PE and FBE. 3PE coated steel pipe have 3 layers of FBE, corrosive, and PE layers, it has integrated advantages of FBE and PE.

Differences between ERW and HFW Steel Pipe

In welded steel pipe production, ERW (Electric Resistance Welded) pipe and HFW (High-Frequency Welded) pipe are two closely related but distinct concepts. ERW refers broadly to the electric resistance welding process, which may use low, medium, or high-frequency currents to generate heat and form the weld. Within this category, HFW pipe is a specific subset […]

Differences between ASTM A53 B and ASTM A106 B Steel Pipe

Differences of ASTM A53 B and ASTM A106 B. ASTM A53 B covers ERW, Seamless and Galvanized steel pipe. A106 B covers only seamless steel pipe for high temperature service.