API 5L B PSL2 Seamless Steel Pipe Manufacturing Process

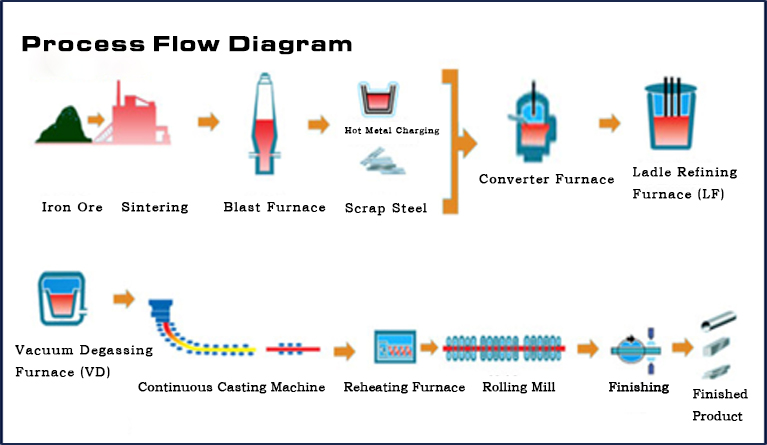

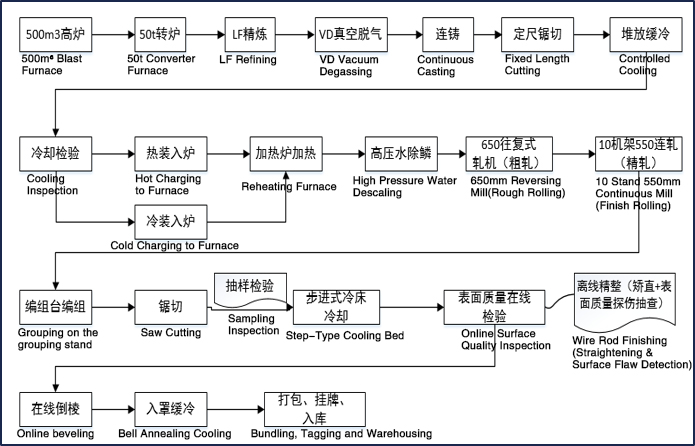

Our company employs advanced integrated steel smelting processes to produce API 5L B PSL2 seamless steel pipes. From raw material processing to final product delivery, the entire process strictly follows international standards. Our smelting process includes blast furnace ironmaking, converter steelmaking, refining treatment, continuous casting, and subsequent rolling operations, ensuring stable and reliable product quality.

Detailed Technical Description

1.Raw Material Preparation and Blast Furnace Ironmaking:

- Iron Ore Processing: High-quality iron ore is processed through sintering technology to produce sinter

- Blast Furnace Smelting: 500m³ blast furnace reduces iron ore with coke to obtain hot metal

- Temperature Control: Blast furnace tapping temperature controlled at 1450-1500°C to ensure hot metal quality

2.Converter Steelmaking and Refining

- Converter Smelting: 50t converter processes hot metal and scrap steel

- Composition Control: Strict control of C, Si, Mn, P, S content to meet API 5L B standards

- LF Refining: Ladle refining furnace for desulfurization, deoxidation, and composition fine-tuning

- VD Vacuum Degassing: Vacuum degassing furnace removes harmful gases like H₂ and N₂, improving steel purity

3. Continuous Casting

- Continuous Casting Process: Continuous casting technology pours refined molten steel into tube billets

- Fixed Length Cutting: Cutting according to specification requirements

- Controlled Cooling: Control cooling rate to prevent internal stress formation

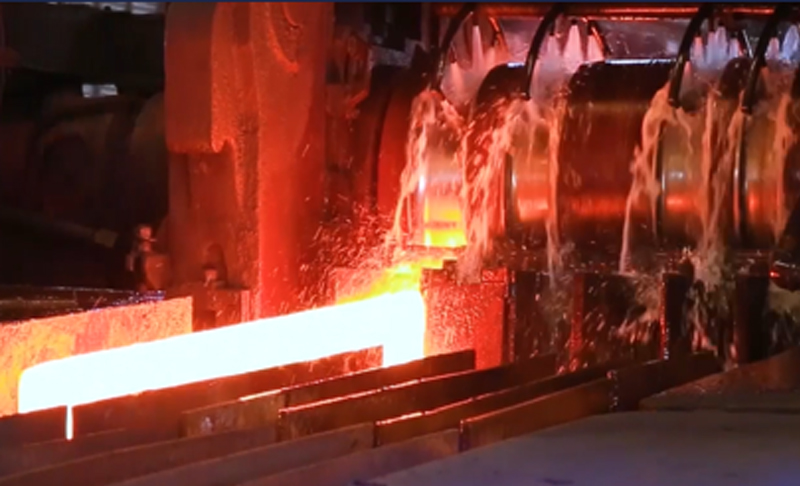

4.Heating and Rolling

- Hot Charging: Hot charging of billets into reheating furnace to reduce energy consumption

- Reheating Furnace: Heating billets to 1200-1250°C rolling temperature

- High Pressure Water Descaling: Removal of surface oxides to ensure surface quality

- Rough Rolling: 650mm reversing mill for rough rolling formation

- Finish Rolling: 10-stand 550mm continuous mill for precision rolling

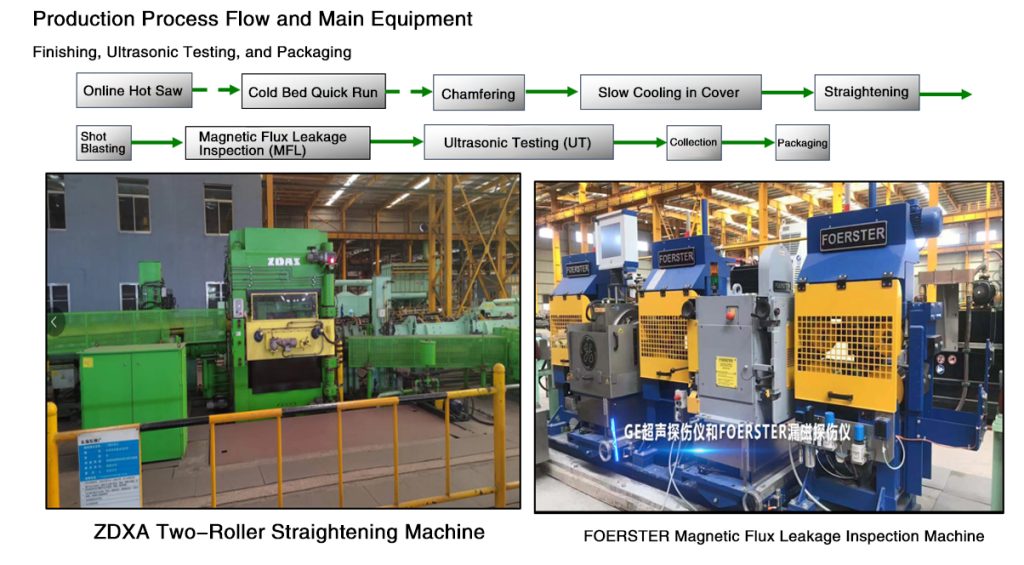

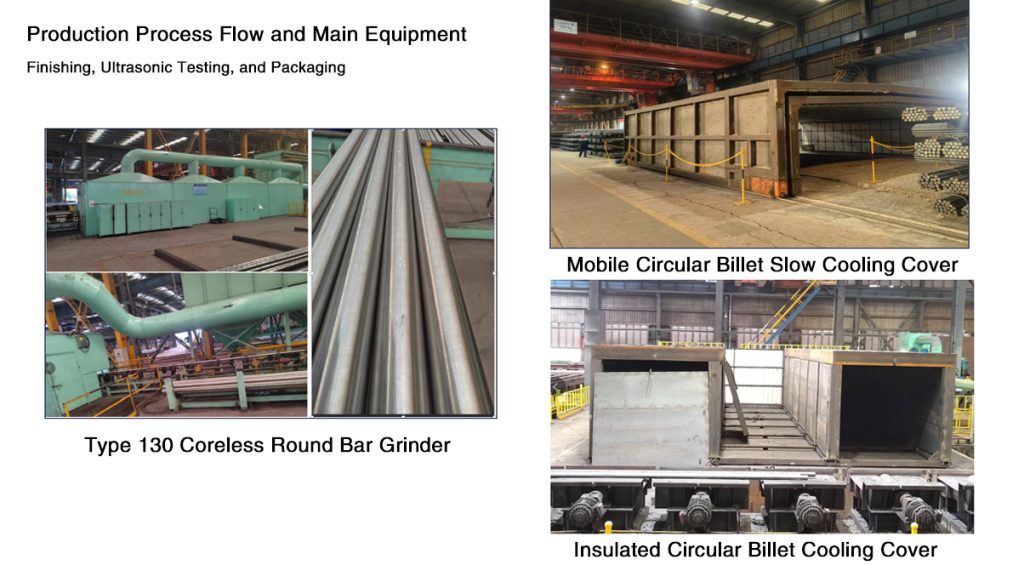

5.Finishing and Quality Control

- Step-Type Cooling Bed: Uniform cooling to eliminate residual stress

- Online Inspection: Online surface quality detection system

- Sampling Inspection: Comprehensive inspection of chemical composition and mechanical properties

- Wire Rod Finishing: Straightening and surface flaw detection

- Product Packaging: Bundling, tagging, and warehouse management

Production Facilities & Quality Certification Gallery

Pipe Manufacturing Process

Production Capacity and Product Specificatins

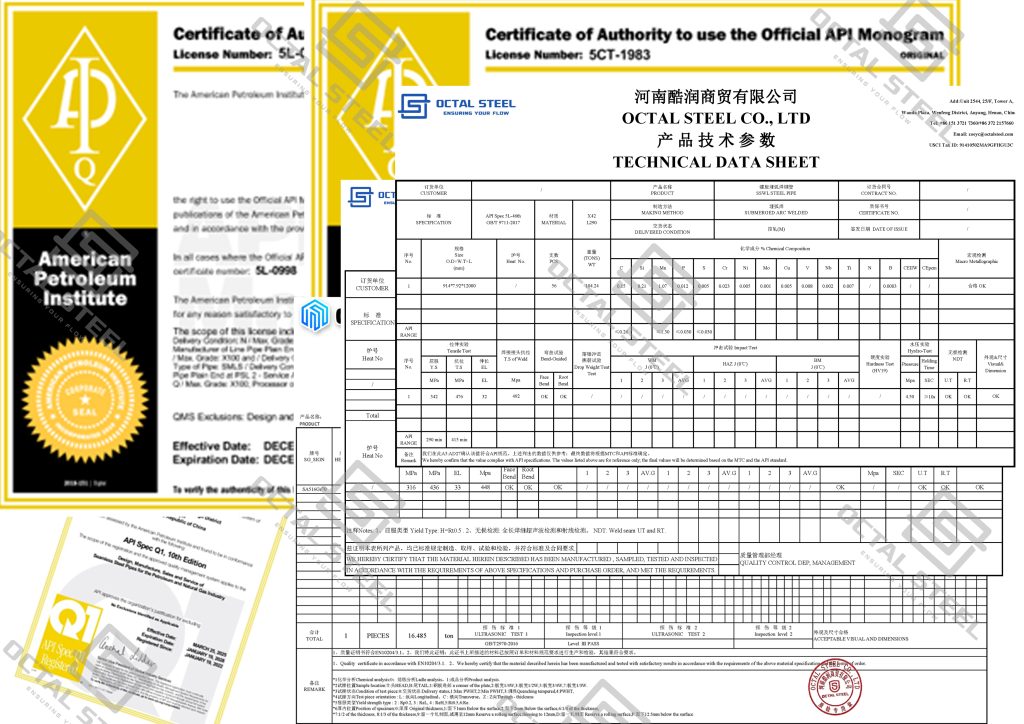

Our company possesses robust production capabilities with an annual total steel output of 600,000 tons, including 400,000 tons of seamless steel pipes, and a monthly capacity of 50,000 tons through 24-hour continuous production operations, capable of meeting large-scale order requirements. Our main products are API 5L B PSL2 seamless steel pipes with outer diameters ranging from 21.3mm to 813mm and wall thickness from 2.5mm to 80mm, strictly controlling chemical composition (C≤0.30%, Mn≤1.40%, P≤0.030%, S≤0.030%, Si 0.15-0.40%) and mechanical properties (yield strength ≥245MPa, tensile strength 415-760MPa, elongation ≥22%) according to API 5L standards. We are equipped with efficient casting furnaces and rolling mills, precision dimension control systems, real-time quality monitoring systems, automated coating equipment, and professional testing equipment, establishing a comprehensive quality assurance system covering chemical composition analysis, mechanical property testing, non-destructive testing, and other comprehensive inspection items. Our products are widely applied in oil & gas, power, mechanical manufacturing, chemical, and construction industries, certified by API 5L, ISO 9001, ISO 14001, and other international standards, providing customers with excellent services including large-volume supply capability, customized production, fast delivery, and complete quality traceability.

Oficinay sucursales

Factory Address: No. 10 Fengyang Road, Luoshe Town, Huishan District, Wuxi City, China

Octal steel Pte.Limitado. Ltd.

Agregar: 8 Kaki Bukit Avenue 4 #03-21 Premier @Kaki Bukit Singapur (415875)

Octal Keerun co.. Ltd.

Dirección: Piso/Habitación 1512, 15.” piso, Lucky Center, n.° 165-171 Wan Chai Road, Wan Chai, Hong Kong

Cooperación internacional de la Industria de Maquinaria de china Co., Ltd.Dirección: Edificio A, n. 18, Carretera Dirun, Nuevo Distrito de Zhengdong, Zhengzhou, Henan, China

Henan Keerun Trading Co., Ltd

Agregar: Unidad 2544, 25/F, Torre A, Centro Wanda, Distrito Wenfeng, Anyang, Henan, China

Octal Enpro (Tianjin) Multinational co., Ltd

Dirección: Edificio Beichen, n.° 4-1114, Tianjin, China

Octal Fujian Keerun Trading Co., Ltd.

Dirección: 23/F, Torre Sur del Centro Guomao, 4686-4688 Xianyue Road, Xiamen, China

Factory Address: No. 10 Fengyang Road, Luoshe Town, Huishan District, Wuxi City, China