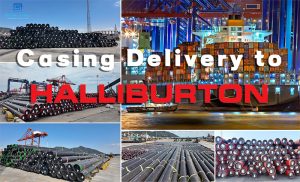

Port Staging & Shipment Workflow (Adjusted for Traceability)

To keep handling safe and traceability clear on a mixed-spec shipment, the port workflow is managed in a few practical phases:

-

Receipt check at the port yard

On arrival, quantities, visible condition, and markings are checked so the staged inventory matches the shipment plan from the start. -

Specification-based staging for fast picking

Casing is staged by OD / weight / length, keeping markings readable and placing bundles where crane/forklift movement is straightforward. This makes it easier to call off the right bundles during loading without re-sorting. -

Sampling checks before packing is finalized

Dimensional and visual checks are performed on a sampling basis when required, with records filed as part of the shipment documentation. -

Protection + export packing

End caps/protectors are installed and rechecked during staging. Where needed, wrapping/separation is used to reduce abrasion and contamination risk. Bundles are strapped with confirmed lifting points and clear tags for stable handling. -

Pre-loading verification, loading, and release

Before container stuffing and loading, bundles are verified against the Packing List, and heat/batch references are confirmed to keep the traceability chain clean. During loading, lashing and reinforcement are applied to reduce shifting risk in ocean transit. Shipment release is completed only when inspection status, packing status, and the final document package are aligned.

Operational detail for mixed-grade cargo: when K55/L80/P110 are shipped together, bundles are staged by grade and size with outward-facing tags to speed cross-checking during loading and reduce the chance of mix-up at discharge and site distribution.